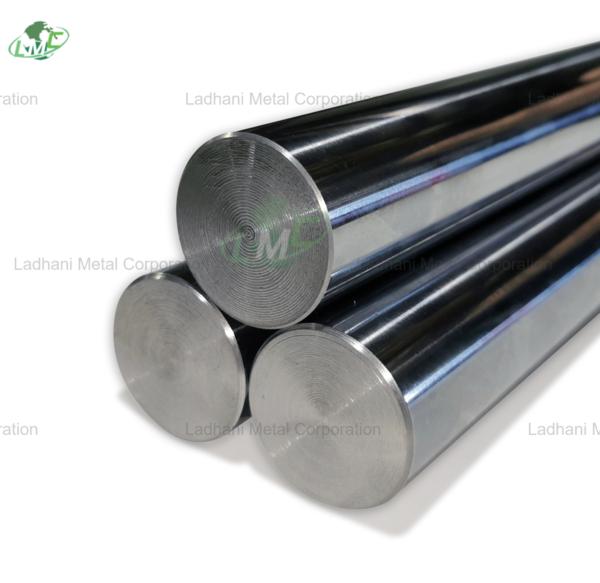

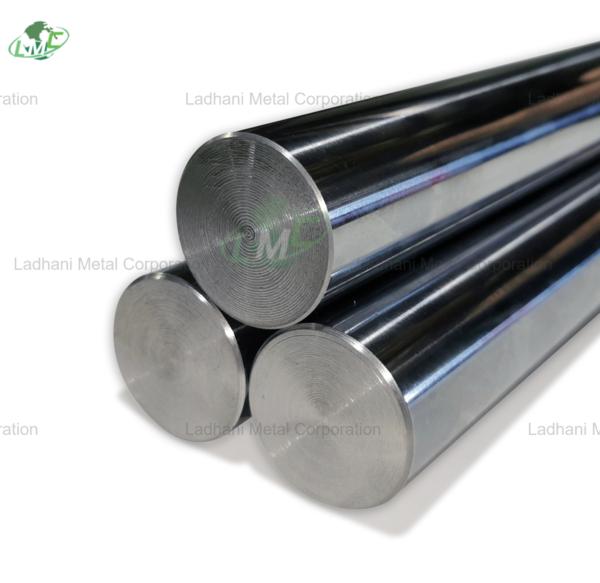

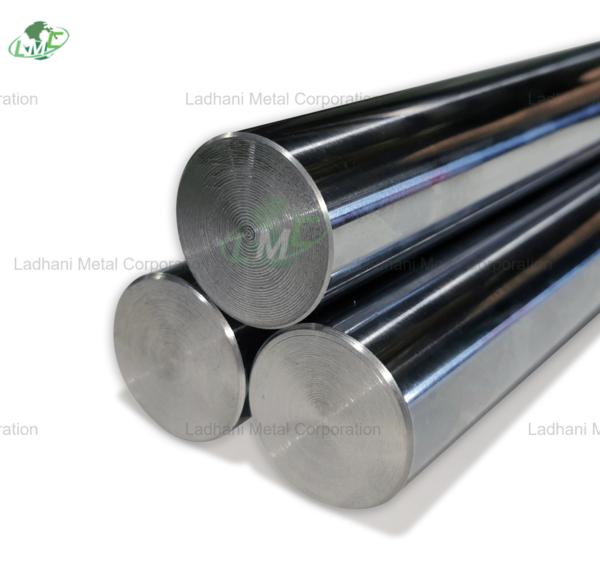

EN 10088-3 X5NiCrTiMoVB25-15-2 is a high-alloy, precipitation-hardenable stainless steel grade engineered for applications requiring very high strength, excellent toughness, and good corrosion resistance under demanding service conditions. Alloyed with nickel, chromium, molybdenum, titanium, vanadium, and boron, this grade offers superior mechanical performance, enhanced hardenability, and stability at elevated temperatures. Supplied in rod form, X5NiCrTiMoVB25-15-2 stainless steel is suitable for advanced engineering, aerospace, and high-stress industrial applications. This grade conforms to the EN 10088-3 standard for stainless steel bars and rods. Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of EN 10088-3 X5NiCrTiMoVB25-15-2 stainless steel rods. Our materials are sourced from approved mills and supplied with controlled chemical composition, consistent mechanical properties, and precise dimensional accuracy in accordance with EN 10088-3 specifications. Forms of Supply: Round bar, hex bar, square bar, rectangular bar, flat bar, rod Explanation of Designation (X5NiCrTiMoVB25-15-2): • X – High-alloy steel • 5 – Approx. 0.05% carbon content • Ni25 – Approx. 25% nickel • Cr15 – Approx. 15% chromium • Mo – Molybdenum alloyed for strength and corrosion resistance • Ti – Titanium for stabilization and precipitation hardening • V – Vanadium for grain refinement and strength • B – Boron for improved hardenability Chemical Composition (% – typical limits): • Carbon (C): ≤ 0.07 • Chromium (Cr): 14.0 – 16.0 • Nickel (Ni): 24.0 – 26.0 • Molybdenum (Mo): 1.5 – 2.5 • Titanium (Ti): 0.3 – 0.7 • Vanadium (V): 0.1 – 0.3 • Boron (B): ≤ 0.010 • Silicon (Si): ≤ 1.00 • Manganese (Mn): ≤ 1.50 • Phosphorus (P): ≤ 0.040 • Sulphur (S): ≤ 0.015 Mechanical Properties (Typical, solution treated and aged): • Tensile Strength: 900 – 1,300 MPa • Yield Strength: ≥ 700 MPa • Elongation: ≥ 10% • Hardness: Typically 300 – 420 HB after aging Key Features: • High-alloy precipitation-hardenable stainless steel • Very high strength and toughness • Good corrosion resistance in aggressive environments • Excellent hardenability and thermal stability • Suitable for high-stress and high-temperature service • Good structural integrity after heat treatment Material Characteristics: EN 10088-3 X5NiCrTiMoVB25-15-2 stainless steel rod delivers an exceptional combination of strength, toughness, and corrosion resistance. Its complex alloying system and precipitation-hardening capability make it suitable for components subjected to extreme mechanical loads and demanding operating conditions. Applications: • Aerospace and defense components • High-strength shafts, rods, and fasteners • Turbine and power-generation parts • Heavy engineering and structural components • Specialized industrial machinery Conclusion: Ladhani Metal Corporation supplies premium-quality EN 10088-3 X5NiCrTiMoVB25-15-2 stainless steel rods with reliable mechanical performance and consistent quality. With very high strength, excellent toughness, and advanced alloy design, X5NiCrTiMoVB25-15-2 stainless steel rod is an ideal choice for critical engineering applications. For size availability, technical specifications, or customized requirements, contact Ladhani Metal Corporation. #EN10088 #EN100883 #EN100883Steel #EN10088StainlessSteel #StainlessSteel #EuropeanStainlessSteel #ENStandardStainlessSteel #EN10088Supplier #EN10088Manufacturer #EN10088Stockist #EN10088Exporter #StainlessSteelBars #StainlessSteelRods #StainlessSteelWire #StainlessSteelBrightBar #SSRoundBar #SSFlatBar #SSHexBar #SSSquareBar #AusteniticStainlessSteel #FerriticStainlessSteel #MartensiticStainlessSteel #DuplexStainlessSteel #304StainlessSteel #304LStainlessSteel #316StainlessSteel #316LStainlessSteel #2205Duplex #StainlessSteelManufacturers #StainlessSteelSuppliers #StainlessSteelStockist #StainlessSteelExporters #IndianStainlessSteel #SSStockist #SSExporter #SteelIndustry #MetalIndustry #EngineeringSteel #IndustrialSteel #CorrosionResistantSteel #HighStrengthStainlessSteel #WeldableStainlessSteel #MachiningSteel #BrightBars #SteelBars #SteelRods #SteelWire #InfrastructureSteel #LadhaniMetal #Mumbai #Delhi #Chennai #Kolkata #Pune #Ahmedabad #Hyderabad #Bengaluru #Coimbatore #Surat #Vadodara #Rajkot #Nashik #Indore #Nagpur #Ludhiana #Faridabad #Noida #Visakhapatnam #Bhubaneswar #Jamshedpur #Patna #Ranchi #Jaipur #Lucknow #Kanpur #Bhopal #Chandigarh #Amritsar #Trivandrum #Kochi #Mangalore #Goa #Aurangabad #Tirupur #Salem #Hosur #Durgapur #Guwahati #Vapi #Ankleshwar #Morbi #Vasai #Thane #Belgaum #Vijayawada #Madurai #Erode #Kolhapur #Hubli #Udaipur #Nagaur #Raipur #Bilaspur #Agra #Varanasi #Meerut #Jodhpur #Surendranagar #Valsad #Bhavnagar