FOR REQUIREMENT OF THIS GRADE OR FOR DETAIL CONTACT US AT :-

LADHANI METAL CORPORATION, MUMBAI, INDIA

Introduction

EN 10025-5

is a European standard that specifies structural steels with improved

atmospheric corrosion resistance, commonly known as weathering steels. These

steels are designed to form a stable, protective oxide layer when exposed to

the atmosphere, significantly reducing corrosion rates and minimizing the need

for surface coatings or maintenance.

EN 10025-5

steels are widely used in outdoor structural applications where long-term

durability, reduced maintenance cost, and aesthetic appearance are required.

The material is suitable for welded, bolted, and riveted constructions and is

supplied in sheet, plate, coil, and strip forms for a wide range of fabrication

and construction needs.

Applicable Standards and Specifications

Standard: EN

10025-5

Material Type: Atmospheric corrosion-resistant structural steel

Product Forms: Sheet, plate, coil, strip

Manufacturing Process: Hot Rolled

Delivery Condition: As Rolled (+AR), Normalized (+N), or Thermomechanically

Rolled (+M) depending on grade

EN 10025-5

steels comply with European structural design codes and are intended for

exposed structural applications.

Available Grades of EN 10025-5 Structural Steel

EN 10025-5

includes multiple grades classified by yield strength, impact toughness, and

delivery condition:

S235J0W,

S235J2W

S355J0W, S355J2W

S355K2W

The suffix

“W” indicates enhanced atmospheric corrosion resistance. Grades with J0, J2, or

K2 indicate impact testing requirements at different temperatures.

Chemical Composition of EN 10025-5 Structural Steel

(%)

S235J0W /

S235J2W

|

Element |

Composition (%) |

|

Carbon (C) |

0.16 max |

|

Manganese

(Mn) |

1.40 max |

|

Phosphorus

(P) |

0.035 max |

|

Sulfur (S) |

0.030 max |

|

Silicon

(Si) |

0.75 max |

|

Copper

(Cu) |

0.25 –

0.55 |

|

Chromium

(Cr) |

0.40 –

1.25 |

|

Nickel

(Ni) |

0.65 max |

S355J0W /

S355J2W / S355K2W

|

Element |

Composition

(%) |

|

Carbon (C) |

0.19 max |

|

Manganese

(Mn) |

1.60 max |

|

Phosphorus

(P) |

0.035 max |

|

Sulfur (S) |

0.030 max |

|

Silicon

(Si) |

0.75 max |

|

Copper

(Cu) |

0.25 –

0.55 |

|

Chromium

(Cr) |

0.40 –

1.25 |

|

Nickel

(Ni) |

0.65 max |

Note: The

combined presence of copper, chromium, nickel, and phosphorus contributes to

the formation of the protective patina layer.

Mechanical Properties of EN 10025-5 Structural Steel

|

Grade |

Yield

Strength (MPa) |

Tensile

Strength (MPa) |

Elongation (%) |

|

S235J0W /

S235J2W |

≥ 235 |

360 – 510 |

≥ 26 |

|

S355J0W /

S355J2W |

≥ 355 |

470 – 630 |

≥ 22 |

|

S355K2W |

≥ 355 |

470 – 630 |

≥ 22 |

Impact test

requirements:

J0 grades tested at 0°C

J2 grades tested at −20°C

K2 grades tested at −20°C with enhanced toughness requirements

Physical Properties (Typical)

Density:

approximately 7.85 g/cm³

Melting Point: approximately 1425 – 1540°C

Thermal Conductivity: approximately 45 – 55 W/m·K

Modulus of Elasticity: approximately 200 GPa

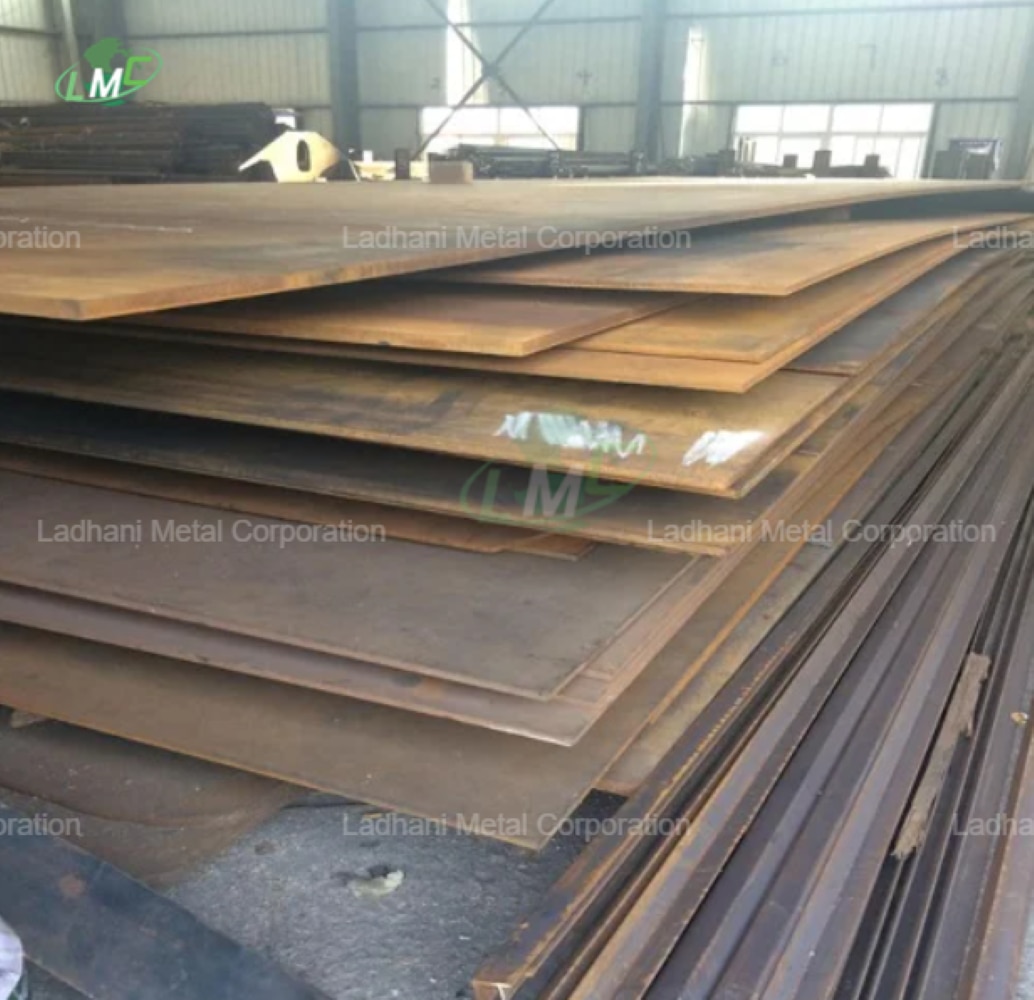

Thickness, Width, and Size Range

Sheet

thickness: 1.5 mm to 6 mm

Plate thickness: 6 mm to 150 mm

Coil thickness: 2 mm to 20 mm

Strip width: from 10 mm onwards

Maximum

width: up to 3000 mm

Length: up to 12000 mm or cut-to-length as required

Material can

be supplied in hot rolled, pickled, or surface-scaled condition.

Key Features of EN 10025-5 Steel Sheet / Plate / Coil

/ Strip

Atmospheric

Corrosion Resistance

EN 10025-5 steels develop a dense, adherent oxide layer when exposed to

atmospheric conditions, significantly slowing further corrosion and extending

service life without coatings.

Low

Maintenance Requirement

Due to the self-protecting patina, structures require minimal painting or

maintenance, reducing lifecycle costs.

Improved

Structural Strength

Higher yield strength grades allow reduced section thickness, resulting in

lighter structures without compromising strength.

Excellent

Weldability

Despite alloying elements for corrosion resistance, EN 10025-5 steels maintain

good weldability using standard welding processes with appropriate consumables.

Attractive

Aesthetic Appearance

The natural rust-like patina provides a distinctive architectural finish,

making these steels popular in architectural and landscaping projects.

Good

Formability and Fabrication

The steel can be easily cut, bent, rolled, and fabricated into complex shapes.

Environmental

Sustainability

Reduced need for paints and coatings lowers environmental impact and long-term

maintenance emissions.

Weldability and Fabrication

EN 10025-5

steels can be welded using SMAW, GMAW, FCAW, and SAW processes. Matching

weathering steel consumables are recommended to maintain corrosion resistance

across weld joints. Preheating is generally not required for thin sections,

while thicker plates may require controlled preheating depending on carbon

equivalent.

Machinability

Machinability

is comparable to conventional structural steels. Proper tool selection and

controlled cutting parameters ensure clean edges and consistent surface finish.

Corrosion Performance Considerations

EN 10025-5

steels perform best in environments with alternating wet and dry conditions.

They are not recommended for permanently wet, submerged, or chloride-rich

environments without additional protection.

Typical Applications of EN 10025-5 Steel Sheet / Plate

/ Coil / Strip

Structural and Construction

Applications

Bridges,

flyovers, and overpasses

Building facades and exposed steel frameworks

Industrial sheds and outdoor structures

Infrastructure and Transportation

Railway

wagons and bridges

Highway structures and sign gantries

Containers and freight equipment

Architectural and Urban Design

Building

cladding and facades

Sculptures and decorative structures

Urban furniture and landscaping elements

Energy and Industrial Applications

Transmission

towers

Power plant structures

Oil and gas secondary structural supports

Heavy Fabrication and Engineering

Material

handling equipment

Earthmoving equipment components

Structural frames exposed to atmosphere

Conclusion

EN 10025-5 Structural Steel Sheet, Plate, Coil, and Strip provide an ideal combination of strength, durability, and atmospheric corrosion resistance. With reduced maintenance requirements, attractive appearance, and excellent fabrication properties, these weathering steels are widely used in bridges, infrastructure, architectural projects, and outdoor structures. When applied in suitable environments, EN 10025-5 steels offer long service life, cost efficiency, and sustainable performance.

For customized sizes, grade

selection, or technical assistance, contact Ladhani Metal Corporation.

FOR REQUIREMENT OF THIS GRADE OR FOR DETAIL CONTACT US AT :-

Product Link:

https://www.indiamart.com/proddetail/en-10025-5-s355k2w-steel-sheet-2858404432191.html?sellerpreview=1

https://www.ladhanimetal.in/products/en-10025-5-s355j2w-steel-strip/3292

https://www.ladhanimetal.in/products/en-10025-5-s355j0w-steel-coil/3291

https://www.ladhanimetal.in/products/en-10025-5-s235j0w-steel-sheet/3289

#EN10025 #EN100255

#EN100255Steel #EN10025StructuralSteel #EN100255StructuralSteel

#WeatheringSteel #AtmosphericCorrosionResistantSteel #CortenEquivalentSteel

#S235J0W #S235J2W #S355J0W #S355J2W #S355K2W #StructuralSteelPlate #StructuralSteelSheet

#StructuralSteelCoil #StructuralSteelStrip #CarbonStructuralSteel

#EuropeanStructuralSteel #ConstructionSteel #SteelForConstruction

#SteelForStructures #BridgeSteel #OutdoorSteel #BuildingSteel #EngineeringSteel

#HeavyEngineeringSteel #FabricationSteel #SteelPlates #SteelSheets #SteelCoils

#SteelStrips #HotRolledSteel #WeatherResistantSteel #HighStrengthSteel

#WeldableSteel #LowCarbonSteel #SteelManufacturers #SteelSuppliers

#SteelExporters #IndianSteel #StructuralSteelSupplier #EN100255Supplier

#EN100255Manufacturer #EN100255Exporter #SteelPlatesIndia #SteelSheetsIndia

#MetalIndustry #IndustrialSteel #InfrastructureSteel #CivilEngineeringSteel

#EuropeanSteelStandard #ENStandardSteel #SteelStockist #SteelTrading

#EN100255SteelSupplier #EN100255SteelManufacturer #EN100255SteelExporter

#LadhaniMetal #Mumbai #NaviMumbai #Thane #Pune #Ahmedabad #Vadodara #Surat

#Rajkot #Jamnagar #Gandhidham #Delhi #Faridabad #Gurugram #Noida #Ghaziabad

#Jaipur #Neemrana #Ludhiana #Jalandhar #Amritsar #Chandigarh #Kolkata #Howrah

#Durgapur #Bokaro #Jamshedpur #Rourkela #Bhubaneswar #Visakhapatnam #Vijayawada

#Hyderabad #Chennai #Coimbatore #Salem #Hosur #Bengaluru #Tumakuru #Belagavi

#Hubballi #Mangaluru #Kochi #Ernakulam #Trivandrum #Nagpur #Nashik #Aurangabad

#Indore #Bhopal #Raipur #Bhilai #Bilaspur #Jabalpur #Ujjain #Kanpur #Lucknow

#Varanasi #Prayagraj