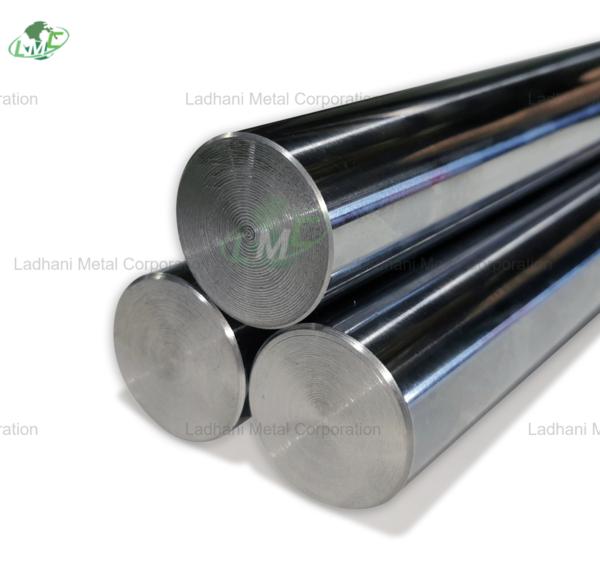

EN 10088-3 X90CrMoV18 is a high-carbon martensitic stainless steel grade developed for applications requiring extremely high hardness, superior wear resistance, and excellent edge retention. Alloyed with chromium, molybdenum, and vanadium, this grade provides outstanding hardenability and enhanced abrasion resistance after heat treatment. Supplied in bar and rod form, X90CrMoV18 stainless steel is widely used in demanding tooling and precision engineering applications. This grade conforms to the EN 10088-3 standard, which specifies technical delivery conditions for stainless steel long products for general purposes. Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of EN 10088-3 X90CrMoV18 stainless steel rods and bars. All materials are sourced from approved mills and supplied in full compliance with EN 10088-3 specifications, ensuring consistent chemical composition, controlled mechanical properties, and precise dimensional accuracy. Forms of Supply: Round bar, hex bar, square bar, rectangular bar, flat bar, rod Explanation of Designation (X90CrMoV18): • X – High-alloy steel • 90 – Approx. 0.90% carbon content • Cr18 – Approx. 18% chromium • Mo – Molybdenum addition for improved hardenability and wear resistance • V – Vanadium addition for grain refinement and enhanced abrasion resistance Chemical Composition (% – typical limits): • Carbon (C): 0.85 – 0.95 • Chromium (Cr): 17.0 – 19.0 • Molybdenum (Mo): 0.80 – 1.20 • Vanadium (V): 0.10 – 0.30 • Silicon (Si): ≤ 1.00 • Manganese (Mn): ≤ 1.00 • Phosphorus (P): ≤ 0.040 • Sulphur (S): ≤ 0.015 Mechanical Properties (Typical, depending on heat treatment): • Tensile Strength: 1,000 – 1,300 MPa • Yield Strength: ≥ 800 MPa • Elongation: 5 – 8% • Hardness: Can be significantly increased by quenching and tempering Key Features: • Ultra-high-carbon martensitic stainless steel • Exceptional hardness and wear resistance • Excellent edge retention and abrasion resistance • Good corrosion resistance for a martensitic grade • Heat-treatable for extreme mechanical performance • Suitable for heavy-duty tooling and precision applications Material Characteristics: EN 10088-3 X90CrMoV18 stainless steel rod and bar delivers outstanding wear resistance and hardness due to its high carbon and alloy content. Its martensitic microstructure, enhanced by molybdenum and vanadium, ensures long service life in severe operating conditions. Applications: • Industrial cutting tools and blades • Dies, punches, and wear plates • Precision tooling and machine components • Bearing and wear-resistant parts • High-load mechanical and engineering applications Conclusion: Ladhani Metal Corporation supplies premium quality EN 10088-3 X90CrMoV18 stainless steel rods and bars in round, hex, square, rectangular, flat, and rod forms. With exceptional hardness potential, superior wear resistance, and reliable corrosion performance, X90CrMoV18 stainless steel bar is an excellent choice for demanding tooling and industrial applications. For size availability or technical assistance, contact Ladhani Metal Corporation. #EN10088 #EN100883 #EN100883Steel #EN10088StainlessSteel #StainlessSteel #EuropeanStainlessSteel #ENStandardStainlessSteel #EN10088Supplier #EN10088Manufacturer #EN10088Stockist #EN10088Exporter #StainlessSteelBars #StainlessSteelRods #StainlessSteelWire #StainlessSteelBrightBar #SSRoundBar #SSFlatBar #SSHexBar #SSSquareBar #AusteniticStainlessSteel #FerriticStainlessSteel #MartensiticStainlessSteel #DuplexStainlessSteel #304StainlessSteel #304LStainlessSteel #316StainlessSteel #316LStainlessSteel #2205Duplex #StainlessSteelManufacturers #StainlessSteelSuppliers #StainlessSteelStockist #StainlessSteelExporters #IndianStainlessSteel #SSStockist #SSExporter #SteelIndustry #MetalIndustry #EngineeringSteel #IndustrialSteel #CorrosionResistantSteel #HighStrengthStainlessSteel #WeldableStainlessSteel #MachiningSteel #BrightBars #SteelBars #SteelRods #SteelWire #InfrastructureSteel #LadhaniMetal #Mumbai #Delhi #Chennai #Kolkata #Pune #Ahmedabad #Hyderabad #Bengaluru #Coimbatore #Surat #Vadodara #Rajkot #Nashik #Indore #Nagpur #Ludhiana #Faridabad #Noida #Visakhapatnam #Bhubaneswar #Jamshedpur #Patna #Ranchi #Jaipur #Lucknow #Kanpur #Bhopal #Chandigarh #Amritsar #Trivandrum #Kochi #Mangalore #Goa #Aurangabad #Tirupur #Salem #Hosur #Durgapur #Guwahati #Vapi #Ankleshwar #Morbi #Vasai #Thane #Belgaum #Vijayawada #Madurai #Erode #Kolhapur #Hubli #Udaipur #Nagaur #Raipur #Bilaspur #Agra #Varanasi #Meerut #Jodhpur #Surendranagar #Valsad #Bhavnagar