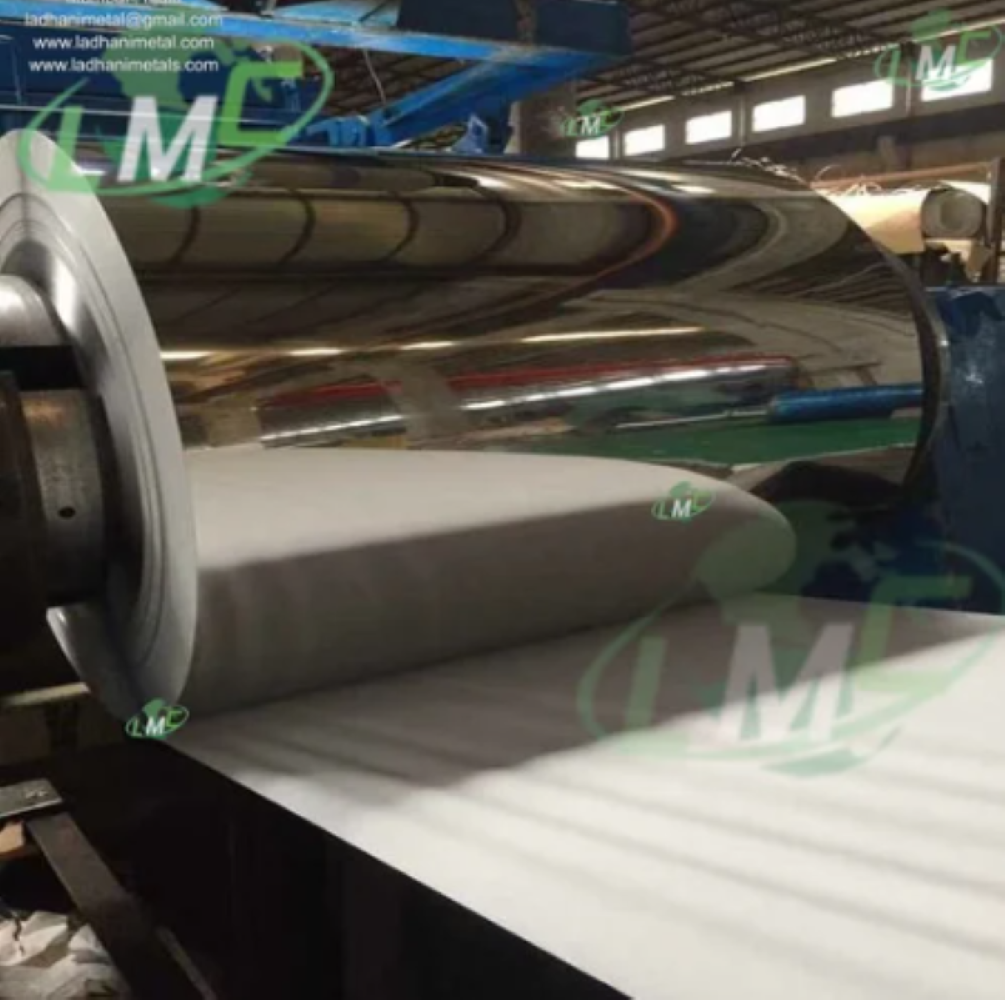

EN 10088 SS X1CrNb15 is a ferritic stainless steel grade containing about 15% chromium and stabilized with niobium. The niobium addition improves weldability, prevents intergranular corrosion, and enhances structural stability by binding carbon and nitrogen. This stabilization ensures excellent resistance to oxidation, scaling, and corrosion, even after welding or prolonged exposure to heat. The material is well-suited for applications requiring strength, thermal stability, and good surface finish. Ladhani Metal Corporation is a reputed manufacturer, supplier, and exporter of EN 10088 SS X1CrNb15 Coil, along with Sheet, Plate, and Strip forms. Our stainless steel coils are produced using high-grade raw materials and advanced manufacturing processes to ensure dimensional accuracy, excellent mechanical strength, and superior corrosion resistance. They are available in various finishes and thicknesses, suitable for industrial, automotive, and decorative use. Forms Available: coil, sheet, plate, strip Chemical Composition (%): • Carbon (C): ≤ 0.04 • Silicon (Si): ≤ 1.00 • Manganese (Mn): ≤ 1.00 • Phosphorus (P): ≤ 0.040 • Sulphur (S): ≤ 0.015 • Chromium (Cr): 14.0 – 16.0 • Niobium (Nb): ≥ 10 × C and ≤ 1.00 Mechanical Properties: • Tensile Strength: 430 – 630 MPa • Yield Strength (0.2% Proof): ≥ 250 MPa • Elongation: ≥ 20% • Hardness (HB): ≤ 200 Key Features: • Excellent corrosion and oxidation resistance • Niobium stabilization improves weldability and prevents sensitization • High strength and dimensional stability under heat • Magnetic ferritic structure with good formability • Resistant to scaling up to 800°C Material Characteristics: EN 10088 SS X1CrNb15 Coil offers a combination of corrosion resistance, thermal stability, and good mechanical strength. The ferritic structure provides reduced thermal expansion and good resistance to chloride stress corrosion cracking. Niobium addition improves grain structure, enhancing toughness and ductility after welding. The material performs well in oxidizing and mildly corrosive environments and maintains a clean, smooth surface finish ideal for both industrial and architectural applications. Applications: • Automotive exhaust systems and trims • Heat exchangers and furnace components • Domestic appliances and kitchen equipment • Building facades and structural cladding • Industrial tanks, pipes, and process equipment Conclusion: Ladhani Metal Corporation supplies premium-quality EN 10088 SS X1CrNb15 Coil, Sheet, Plate, and Strip designed for long-term durability, corrosion resistance, and reliable performance. Our coils are available in various grades, tempers, and finishes to meet diverse industrial requirements. For detailed technical information, custom dimensions, or material inquiries, please contact Ladhani Metal Corporation – your trusted partner for stainless steel solutions. #Mumbai #Delhi #Chennai #Kolkata #Pune #Ahmedabad #Hyderabad #Bengaluru #Coimbatore #Surat #Vadodara #Rajkot #Nashik #Indore #Nagpur #Ludhiana #Faridabad #Noida #Visakhapatnam #Bhubaneswar #Jamshedpur #Patna #Ranchi #Jaipur #Lucknow #Kanpur #Bhopal #Chandigarh #Amritsar #Trivandrum #Kochi #Mangalore #Goa #Aurangabad #Tirupur #Salem #Hosur #Durgapur #Guwahati #Vapi #Ankleshwar #Morbi #Vasai #Thane #Belgaum #Vijayawada #Madurai #Erode #Kolhapur #Hubli #Udaipur #Nagaur #Raipur #Bilaspur #Agra #Varanasi #Meerut #Jodhpur #Surendranagar #Valsad #Bhavnagar #EN10088 #EN10088StainlessSteel #En10088SheetPlateCoilStrip #SSSheet #SSPlate #SSCoil #SSStrip #ColdRolledSteel #HotRolledSteel #CustomFabrication #CorrosionResistantSteel #DurableSteel #PrecisionEngineered #EN10088SSManufacturer #EN10088SSSupplier #EN10088SSExporter #ISOApproved #InternationalGradeSteel #HighPerformanceSteel #IndustrialSheet #IndustrialPlate #IndustrialCoil #IndustrialStrip #StainlessSteelSupplier #StainlessSteelManufacturer #StainlessSteelExporter #MetalFabrication #IndustrialApplications #ConstructionMaterials #EngineeringMaterials #OEMApplications #LadhaniMetals #MetalSupplier #MetalExporter #SteelIndustry #MarineSteelApplications #AutomotiveSteelApplications #ChemicalProcessingSteel #FoodProcessingSteel #PharmaGradeSteel #PowerGenerationSteel #HeatExchangerSteel #WaterTreatmentSteel #ArchitecturalSteel #IndustrialEquipmentSteel #CustomMetalSolutions #GlobalExporter #IndianManufacturer #TechnicalSpecifications #MaterialStandards #SteelFabricator #IndustrialSupplier #StainlessSteelIndia #StainlessSteelExporters #IndustrialMetals #MetalSheets #MetalPlates #MetalCoils #MetalStrips #SheetMetalProcessing #SteelFabrication #EngineeringProjects #OEMMetalSolutions #HighQualitySteel #LongLifeMaterial #FabricationMaterials #IndustrialSteel #StainlessSteelProducts