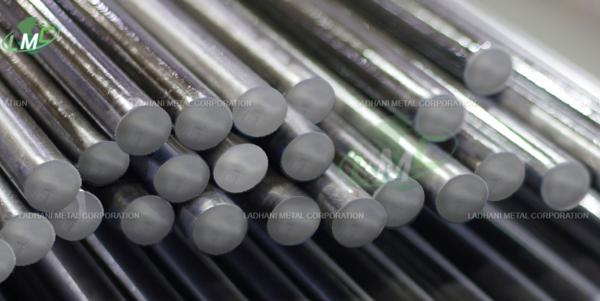

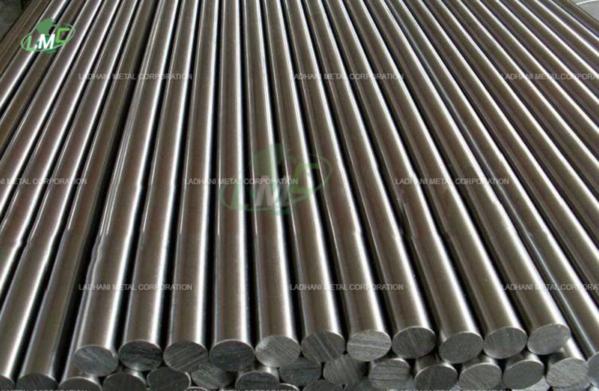

EN 10083-2 C45R is a medium carbon non-alloy steel grade supplied in the as-rolled (R) condition, suitable for applications requiring high strength, good toughness, and economical processing without additional heat treatment. With a nominal carbon content of around 0.45%, C45R steel provides higher strength and hardness than C35 and C40 grades, making it suitable for components subjected to moderate to high mechanical stress. Supplied in bar form, EN 10083-2 C45R steel is widely used in general engineering and mechanical manufacturing applications. This grade is manufactured in accordance with EN 10083-2, which specifies technical delivery conditions for quenched and tempered steels. Ladhani Metal Corporation is a reliable manufacturer, supplier, and exporter of EN 10083-2 C45R steel bars. Our materials are sourced from approved mills and supplied with controlled chemical composition, consistent mechanical properties, and precise dimensional accuracy as per EN 10083-2 requirements. Forms of Supply (as per grade): Black round bar, bright round bar, peeled bar, hex bar, square bar, flat bar, forged bar Explanation of Designation (C45R): • C – Carbon steel • 45 – Approx. 0.45% carbon content • R – Supplied in as-rolled condition Chemical Composition (% – typical limits): • Carbon (C): 0.42 – 0.50 • Manganese (Mn): 0.50 – 0.80 • Silicon (Si): ≤ 0.40 • Phosphorus (P): ≤ 0.035 • Sulphur (S): ≤ 0.035 Mechanical Properties (Typical, as-rolled): • Tensile Strength: 600 – 750 MPa • Yield Strength: ≥ 340 MPa • Elongation: ≥ 14% • Hardness: 180 – 220 HB Key Features: • Medium carbon steel supplied in as-rolled condition • High strength and hardness without heat treatment • Cost-effective and readily available material • Good machinability for standard machining operations • Suitable for welding with proper precautions Material Characteristics: EN 10083-2 C45R steel bar provides a strong balance of strength, toughness, and machinability in the as-rolled condition. Its higher carbon content ensures superior mechanical performance for moderately to heavily loaded components while maintaining economical processing. Applications: • Shafts, axles, and pins • Gears, couplings, and keys • Mechanical and structural components • Forged and machined parts • Automotive and general engineering parts Conclusion: Ladhani Metal Corporation supplies high-quality EN 10083-2 C45R steel bars in a wide range of industrial bar forms with consistent quality and dependable performance. With high strength, ease of processing, and economical pricing, C45R steel bars are a reliable choice for general engineering and mechanical applications. For size availability, technical specifications, or customized requirements, contact Ladhani Metal Corporation. #EN10083 #EN100832 #EN100832Steel #EN10083CarbonSteel #EN10083EngineeringSteel #ENStandardSteel #CarbonSteel #MediumCarbonSteel #C22E #C25E #C30E #C35E #C40E #C45E #C50E #C55E #EngineeringSteelBars #CarbonSteelBars #CarbonSteelRods #RoundBar #FlatBar #SquareBar #HexBar #ForgingSteel #MachinerySteel #AutomotiveSteel #MechanicalSteel #ShaftSteel #GearSteel #AxleSteel #BoltSteel #MachinePartsSteel #HeatTreatableSteel #NormalizedSteel #AnnealedSteel #QuenchedTemperedSteel #SteelManufacturers #SteelSuppliers #SteelStockist #SteelExporter #IndianSteel #CarbonSteelSupplier #EN100832Supplier #EN100832Manufacturer #EN100832Exporter #SteelBarsIndia #SteelRodsIndia #MetalIndustry #IndustrialSteel #InfrastructureSteel #EngineeringIndustry #HeavyEngineeringSteel #FabricationSteel #SteelTrading #SteelWholesale #LadhaniMetal #Mumbai #Delhi #Chennai #Kolkata #Pune #Ahmedabad #Hyderabad #Bengaluru #Coimbatore #Surat #Vadodara #Rajkot #Nashik #Indore #Nagpur #Ludhiana #Faridabad #Noida #Visakhapatnam #Bhubaneswar #Jamshedpur #Patna #Ranchi #Jaipur #Lucknow #Kanpur #Bhopal #Chandigarh #Amritsar #Kochi #Trivandrum #Goa #Aurangabad #Salem #Hosur #Durgapur #Guwahati #Vapi #Ankleshwar #Morbi #Thane #Belgaum #Vijayawada #Madurai #Erode #Kolhapur #Hubli #Udaipur #Raipur #Bilaspur #Agra #Varanasi #Meerut #Jodhpur #Bhavnagar