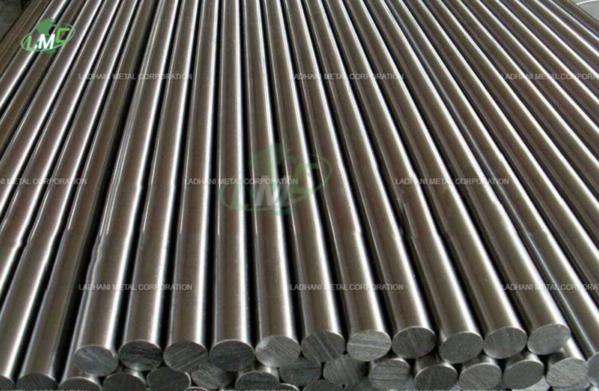

EN 10083-2 C60R is a very high carbon non-alloy steel grade supplied in the as-rolled (R) condition, suitable for applications requiring high strength, good hardness, and wear resistance with cost-effective processing without additional heat treatment. With a nominal carbon content of around 0.60%, C60R steel provides higher hardness and tensile strength than lower carbon grades, making it suitable for components subjected to heavy mechanical loads and abrasive conditions. Supplied in bar form, EN 10083-2 C60R steel is widely used in general engineering, automotive, and industrial manufacturing. This grade is manufactured in accordance with EN 10083-2, which specifies technical delivery conditions for quenched and tempered steels. Ladhani Metal Corporation is a reliable manufacturer, supplier, and exporter of EN 10083-2 C60R steel bars. Our materials are sourced from approved mills and supplied with controlled chemical composition, consistent mechanical properties, and precise dimensional accuracy as per EN 10083-2 requirements. Forms of Supply (as per grade): Black round bar, bright round bar, peeled bar, hex bar, square bar, flat bar, forged bar Explanation of Designation (C60R): • C – Carbon steel • 60 – Approx. 0.60% carbon content • R – Supplied in as-rolled condition Chemical Composition (% – typical limits): • Carbon (C): 0.57 – 0.65 • Manganese (Mn): 0.60 – 0.90 • Silicon (Si): ≤ 0.40 • Phosphorus (P): ≤ 0.035 • Sulphur (S): ≤ 0.035 Mechanical Properties (Typical, as-rolled): • Tensile Strength: 750 – 900 MPa • Yield Strength: ≥ 400 MPa • Elongation: ≥ 8% • Hardness: 220 – 270 HB Key Features: • Very high carbon steel supplied in as-rolled condition • High strength and hardness without additional heat treatment • Good wear resistance for heavily loaded components • Economical and readily available material • Suitable for welding with controlled procedures Material Characteristics: EN 10083-2 C60R steel bar provides very high strength, hardness, and wear resistance in the as-rolled condition. Its high carbon content ensures reliable performance for heavily stressed and wear-prone components while maintaining cost efficiency. Applications: • Shafts, axles, and pins • Gears, cams, and wear parts • Mechanical and structural components • Forged and machined parts • Heavy-duty engineering and industrial applications Conclusion: Ladhani Metal Corporation supplies high-quality EN 10083-2 C60R steel bars in a wide range of industrial bar forms with consistent quality and dependable performance. With very high strength, good wear resistance, and economical processing, C60R steel bars are a reliable choice for demanding mechanical and engineering applications. For size availability, technical specifications, or customized requirements, contact Ladhani Metal Corporation. #EN10083 #EN100832 #EN100832Steel #EN10083CarbonSteel #EN10083EngineeringSteel #ENStandardSteel #CarbonSteel #MediumCarbonSteel #C22E #C25E #C30E #C35E #C40E #C45E #C50E #C55E #EngineeringSteelBars #CarbonSteelBars #CarbonSteelRods #RoundBar #FlatBar #SquareBar #HexBar #ForgingSteel #MachinerySteel #AutomotiveSteel #MechanicalSteel #ShaftSteel #GearSteel #AxleSteel #BoltSteel #MachinePartsSteel #HeatTreatableSteel #NormalizedSteel #AnnealedSteel #QuenchedTemperedSteel #SteelManufacturers #SteelSuppliers #SteelStockist #SteelExporter #IndianSteel #CarbonSteelSupplier #EN100832Supplier #EN100832Manufacturer #EN100832Exporter #SteelBarsIndia #SteelRodsIndia #MetalIndustry #IndustrialSteel #InfrastructureSteel #EngineeringIndustry #HeavyEngineeringSteel #FabricationSteel #SteelTrading #SteelWholesale #LadhaniMetal #Mumbai #Delhi #Chennai #Kolkata #Pune #Ahmedabad #Hyderabad #Bengaluru #Coimbatore #Surat #Vadodara #Rajkot #Nashik #Indore #Nagpur #Ludhiana #Faridabad #Noida #Visakhapatnam #Bhubaneswar #Jamshedpur #Patna #Ranchi #Jaipur #Lucknow #Kanpur #Bhopal #Chandigarh #Amritsar #Kochi #Trivandrum #Goa #Aurangabad #Salem #Hosur #Durgapur #Guwahati #Vapi #Ankleshwar #Morbi #Thane #Belgaum #Vijayawada #Madurai #Erode #Kolhapur #Hubli #Udaipur #Raipur #Bilaspur #Agra #Varanasi #Meerut #Jodhpur #Bhavnagar