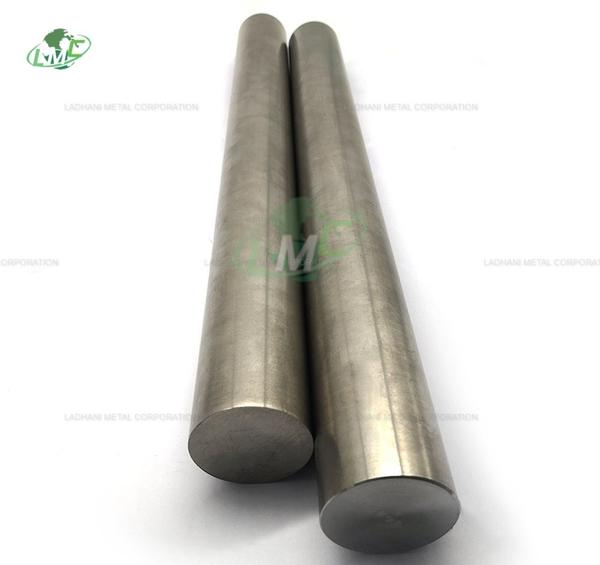

EN 10084 22CrMoS3-5 is a low alloy chromium-molybdenum carburizing steel grade with controlled sulphur content, designed for components requiring a hard, wear-resistant surface along with a strong and tough core after carburizing and heat treatment. With approximately 0.22% carbon and alloying elements such as chromium and molybdenum, this grade provides enhanced hardenability, improved core strength, and excellent fatigue resistance. The added sulphur improves machinability compared to non-sulphurized grades. Manufactured in accordance with EN 10084, which specifies technical delivery conditions for steels intended for carburizing treatment, 22CrMoS3-5 steel is widely used in automotive, heavy engineering, and power transmission industries. The chromium improves depth of hardening and wear resistance, molybdenum enhances tempering resistance and strength, and the sulphur content ensures efficient machining before heat treatment. Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of EN 10084 22CrMoS3-5 round bars, supplied with mill test certificates and strict quality inspection as per European standards. Forms of Supply (as per grade): Hot rolled round bars, Black round bars, Bright round bars, Peeled bars, Turned bars, Ground bars, Forged round bars Explanation of Designation (22CrMoS3-5): • 22 – Approx. 0.22% carbon content • Cr – Chromium alloyed steel • Mo – Molybdenum alloyed steel • S – Increased sulphur content for improved machinability • 3-5 – Alloy content classification Chemical Composition (% – typical limits): • Carbon (C): 0.19 – 0.25 • Manganese (Mn): 0.60 – 0.90 • Silicon (Si): ≤ 0.40 • Chromium (Cr): 0.60 – 0.90 • Molybdenum (Mo): 0.15 – 0.30 • Phosphorus (P): ≤ 0.025 • Sulphur (S): 0.020 – 0.040 Mechanical Properties (Core, typical normalized condition): • Tensile Strength: 900 – 1100 MPa • Yield Strength: ≥ 650 MPa • Elongation: ≥ 8% • Hardness (Core): 240 – 300 HB After carburizing and quenching, the surface hardness can reach approximately 58 – 62 HRC, depending on case depth and heat treatment conditions. Key Features: • Excellent carburizing response • High hardenability due to Cr and Mo additions • Improved machinability from controlled sulphur content • High core strength and fatigue resistance • Good tempering resistance Material Characteristics: EN 10084 22CrMoS3-5 round bars provide a combination of deep case hardening capability and strong core properties. The chromium and molybdenum improve wear resistance and strength retention, while sulphur ensures better machining efficiency before heat treatment. Applications: • Heavy-duty gears and gear shafts • Transmission components • Drive shafts and axles • Pinions and sprockets • Automotive drivetrain parts • Industrial machinery components requiring deep case hardening Conclusion: Ladhani Metal Corporation supplies high-quality EN 10084 22CrMoS3-5 round bars in various diameters and finishes. With enhanced hardenability, strong core strength, and improved machinability, 22CrMoS3-5 steel is widely used in automotive and industrial engineering applications requiring durable, case-hardened components. For stock availability, customized sizes, or technical specifications, contact Ladhani Metal Corporation. #EN10084 #EN10084Steel #EN10084Bars #EN10084CarburizingSteel #EN10084CaseHardeningSteel #ENStandardSteel #AlloySteel #CaseHardeningSteel #CarburizingSteel #C10E #C15E #C16E #16MnCr5 #20MnCr5 #18CrNiMo76 #17Cr3 #20MnCrS5 #EngineeringSteelBars #AlloySteelBars #AlloySteelRods #RoundBar #FlatBar #SquareBar #HexBar #ForgingSteel #MachinerySteel #AutomotiveSteel #MechanicalSteel #GearSteel #PinionSteel #ShaftSteel #TransmissionSteel #HeatTreatableSteel #CaseHardenedSteel #SteelManufacturers #SteelSuppliers #SteelStockist #SteelExporter #IndianSteel #AlloySteelSupplier #EN10084Supplier #EN10084Manufacturer #EN10084Exporter #SteelBarsIndia #SteelRodsIndia #MetalIndustry #IndustrialSteel #EngineeringIndustry #HeavyEngineeringSteel #FabricationSteel #SteelTrading #SteelWholesale #LadhaniMetal #Mumbai #Delhi #Chennai #Kolkata #Bengaluru #Hyderabad #Ahmedabad #Pune #Surat #Jaipur #Lucknow #Kanpur #Nagpur #Indore #Thane #Bhopal #Visakhapatnam #Patna #Vadodara #Ghaziabad #Ludhiana #Coimbatore #Agra #Madurai #Nashik #Faridabad #Meerut #Rajkot #Varanasi #Srinagar #Aurangabad #Dhanbad #Amritsar #NaviMumbai #Allahabad #Ranchi #Howrah #Jabalpur #Gwalior #Vijayawada #Jodhpur #Raipur #Kota #Guwahati #Chandigarh #Solapur #Hubli #Mysuru #Tiruchirappalli #Bareilly