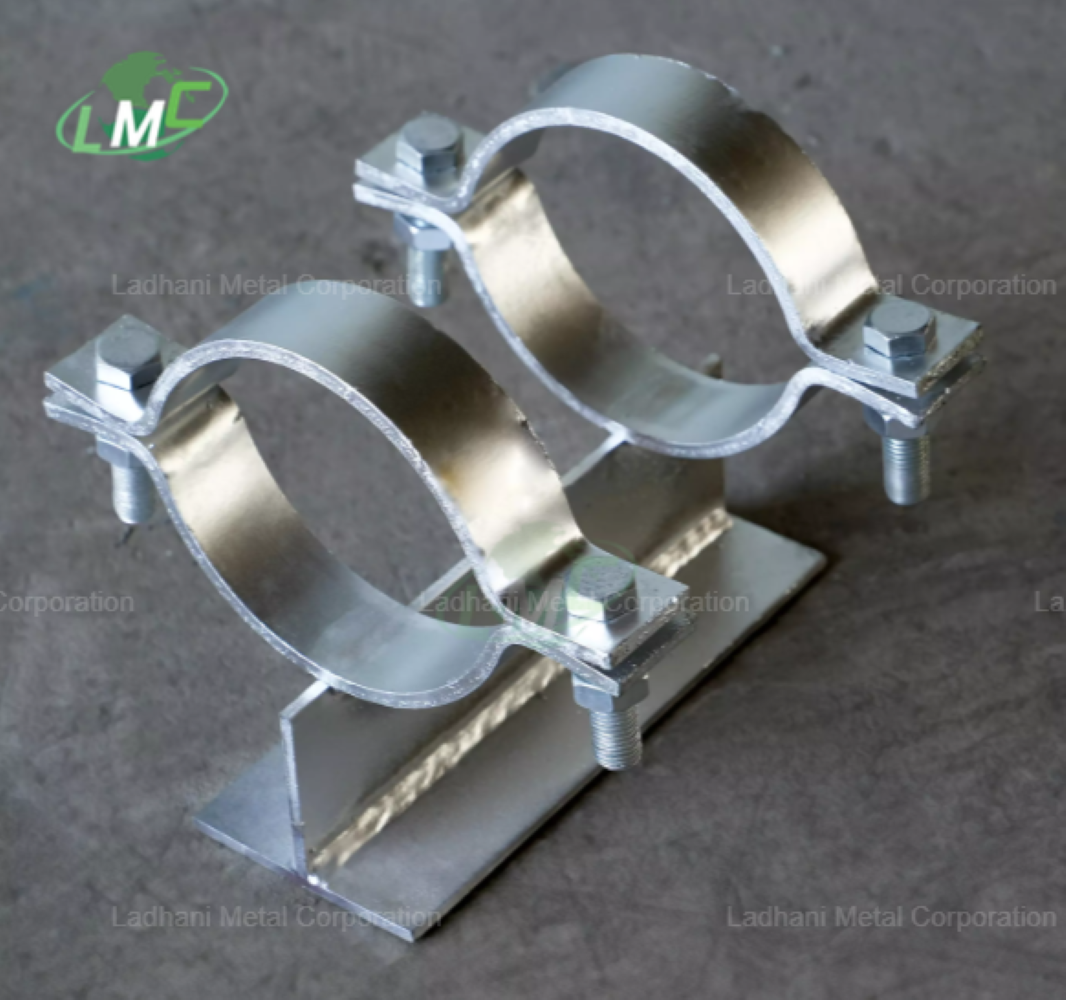

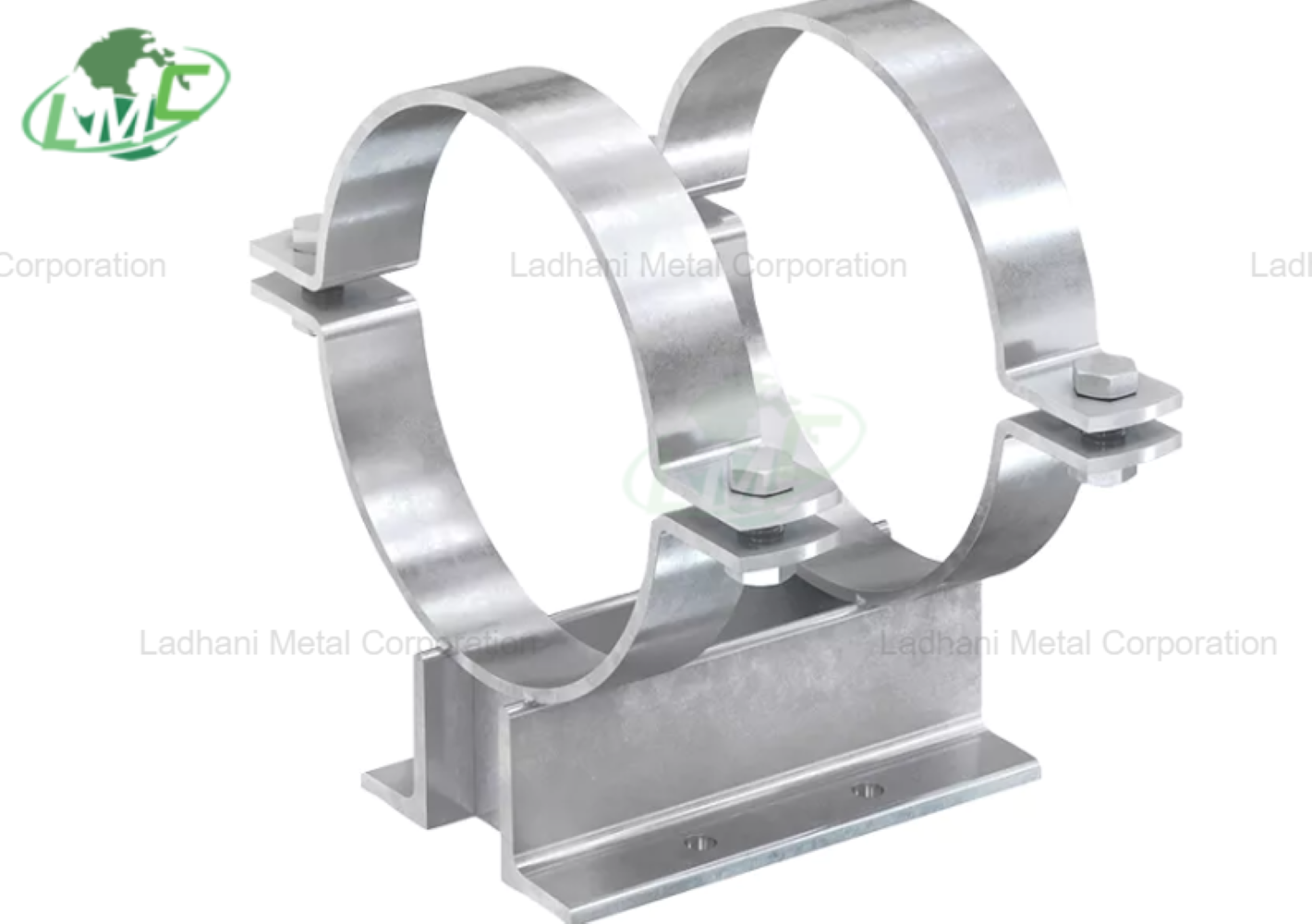

Half Round Tube Shield Half Round Tube Shields by Ladhani Metal Corporation are precision-engineered components designed to protect boiler tubes, superheaters, and heat exchanger coils from erosion, scaling, high-temperature oxidation, and mechanical wear. These shields are widely used in thermal power plants, petrochemical systems, and process industries where tubes are exposed to harsh operating conditions such as high-velocity flue gases, slag, and thermal cycling. Their semi-cylindrical shape allows for easy installation over both straight and curved tube surfaces without system disassembly. SS 410 U Type Inner Half Round Tube Shield The SS 410 U Type Inner Half Round Tube Shield is manufactured from martensitic stainless steel grade 410, which offers good corrosion resistance, excellent wear resistance, and moderate high-temperature strength. The inner U-type design is specifically configured to cover the internal arc of U-bend tubes, an area especially prone to erosion caused by turbulence, thermal gradients, and high-velocity gas impingement. SS 410 provides a hard, durable barrier against mechanical and thermal stress in industrial heat transfer equipment. • Inner U Type Half Round Tube Shield – Protects the internal bend of U-bend tubes from erosion, slag buildup, and high-temperature wear. Ladhani Metal Corporation is a dependable manufacturer, supplier, and exporter of SS 410 U Type Inner Half Round Tube Shields, offering cost-effective and durable protection solutions for critical tube components in high-temperature service environments. Chemical Composition of SS 410 – Martensitic Stainless Steel • Carbon (C): 0.08 – 0.15% • Manganese (Mn): ≤ 1.00% • Phosphorus (P): ≤ 0.040% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 11.5 – 13.5% • Nickel (Ni): ≤ 0.75% • Iron (Fe): Balance Applications: Best suited for moderate to high-temperature environments where abrasion resistance, mechanical strength, and oxidation resistance are important. Uses • Inner arc shielding of U-bend tubes in power plant boilers and superheaters exposed to flue gas turbulence • Protection of return bends in WHRBs and HRSGs where scaling and erosion are common • Applied in curved tube sections in steam reformers, furnaces, and heat exchangers • Ideal for use in chemical, cement, and metallurgical plants with abrasive flue gas and slag exposure • Suitable for systems requiring enhanced wear resistance under cyclic thermal loading Features • Good high-temperature oxidation resistance – Performs well in oxidizing atmospheres up to 650°C • Inner bend protection – Focused coverage for the area most affected by turbulent gas flow and erosion • Wear resistance – Offers excellent surface hardness and mechanical strength for long-term use • Secure fit – Custom-manufactured to match the tube’s radius and diameter for effective shielding • Quick installation – Can be fixed using clamp-on, banding, or welding techniques depending on system requirements • Cost-effective performance – Provides a durable and affordable solution for erosion and heat protection Applications • thermal power plants – Shields inner U-bends in boiler and superheater sections from erosion and slag impact • waste heat recovery systems – Used in WHRBs and HRSGs to protect internal tube arcs from scale and corrosion • petrochemical facilities – Installed in curved tube coils and return bends exposed to acidic and abrasive gas streams • industrial furnaces and reformers – Suitable for inner arc coverage in high-temperature gas flow zones • cement and chemical plants – Defends against mechanical wear and heat stress in return tube bends Conclusion The SS 410 U Type Inner Half Round Tube Shield by Ladhani Metal Corporation – manufacturer, supplier, and exporter – is a durable and cost-efficient solution for shielding the inner arc of U-bend tubes in thermally and mechanically demanding environments. Its martensitic structure and wear-resistant properties make it a reliable choice for protecting tube surfaces from erosion, scaling, and heat-induced damage in power and process applications. For custom orders, technical support, or quotations, please contact Ladhani Metal Corporation.

Send Message