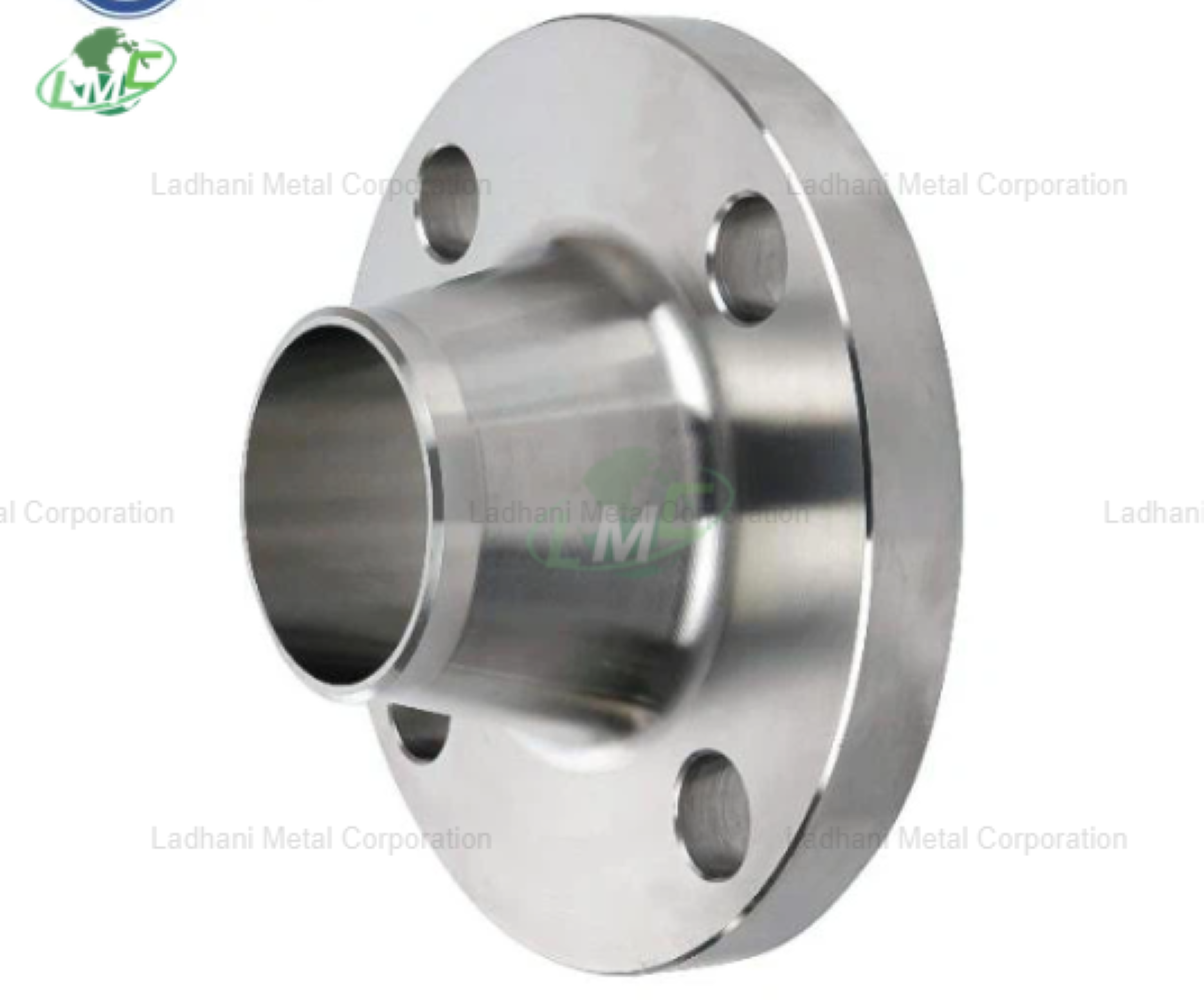

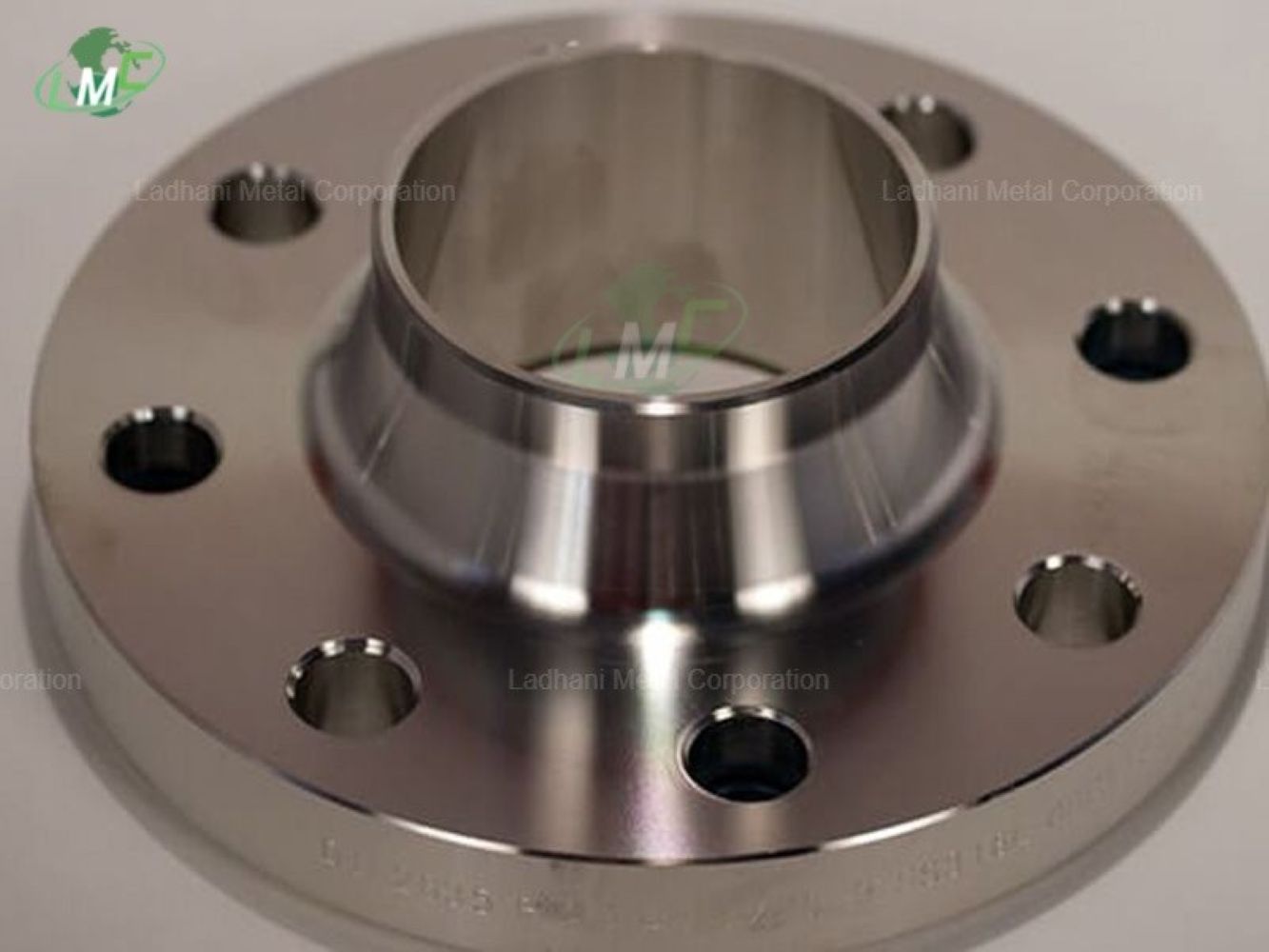

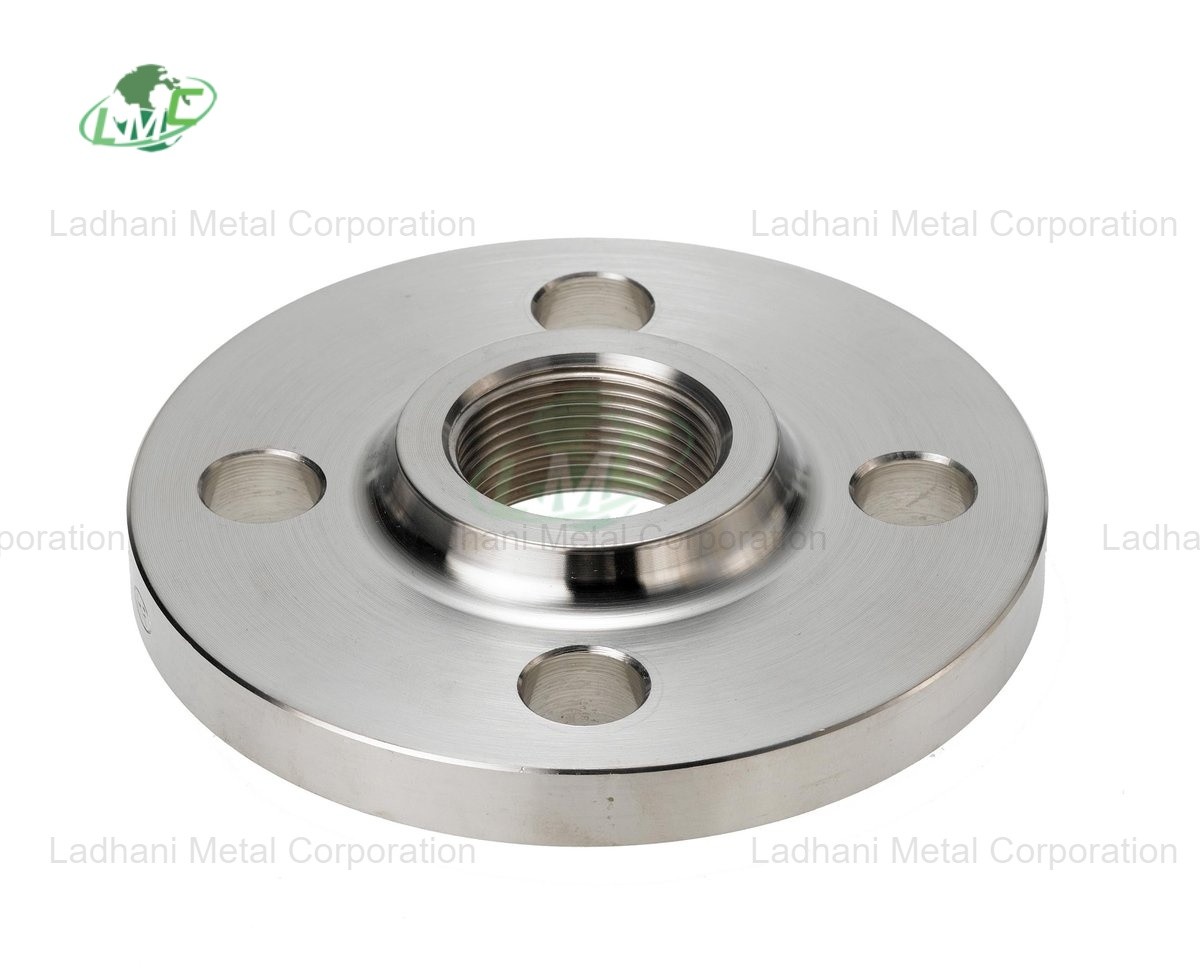

DIN 2634 carbon steel flanges PN 25 are high-strength weld neck flanges manufactured according to the DIN 2634 standard. Specifically designed for use in high-pressure piping systems operating up to 25 bar (362 psi), these flanges offer excellent mechanical performance and are suitable for a wide range of industrial applications. Manufactured from quality carbon steel, they provide strong, durable, and cost-effective solutions for systems where corrosion resistance requirements are moderate but structural integrity is critical. Ladhani Metal Corporation is a recognized manufacturer and global supplier of carbon steel flanges, known for precision engineering, strict adherence to international standards, and advanced production capabilities. Each flange is subject to comprehensive testing and inspection to ensure reliability and consistent performance under demanding operating conditions. Pressure Rating: • PN 25 (25 bar / 362 psi): Suitable for medium to high-pressure applications where strength and impact resistance are essential. Flange Type: • Weld Neck Flanges Designed with a tapered hub to ensure smooth transition from flange to pipe, weld neck flanges are ideal for systems experiencing frequent thermal cycling, pressure fluctuations, and mechanical stress. • Flat Face (FF) Flanges Recommended for use with gaskets made from soft materials or when connecting to cast iron components, flat face flanges ensure even gasket compression and reliable sealing performance. Carbon Steel Grades and Typical Composition: Carbon Steel (ASTM A105 / C22.8 equivalent) – Forged Carbon Steel • Carbon (C): ≤ 0.35% • Manganese (Mn): 0.60 – 1.05% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.040% • Silicon (Si): 0.10 – 0.35% • Iron (Fe): Balance Applications: Commonly used in oil and gas, petrochemical, water transmission, and power generation industries, especially in applications where high mechanical strength and pressure handling are more critical than corrosion resistance. Applications of DIN 2634 Carbon Steel Flanges PN 25: • Oil and Gas Pipelines Widely used in upstream and downstream systems for fluid transport under high pressure. • Petrochemical and Refining Plants Efficiently handles high-pressure flow systems involving hydrocarbons and steam. • Power Plants and Boiler Systems Suited for high-pressure steam and water lines, offering excellent tensile strength and fatigue resistance. • Water and Wastewater Infrastructure Used in municipal and industrial pipelines requiring cost-effective, robust flange connections. • General Industrial Systems Applicable in a wide range of mechanical systems and processing plants handling non-corrosive or mildly corrosive media. Key Features: • Compliant with DIN 2634 pressure and dimensional standards • PN 25 rating ensures compatibility with high-pressure pipelines • High tensile and yield strength for demanding structural requirements • Weld neck design enhances resistance to vibration and thermal expansion • Cost-effective solution for pressure-bearing connections • Available in standard and custom sizes, surface finishes, and pressure ratings • Heat treatment and coating options available upon request Conclusion: DIN 2634 carbon steel flanges PN 25 from Ladhani Metal Corporation provide a robust and economical solution for high-pressure systems where mechanical performance is essential. Their strength, reliability, and adaptability make them a preferred choice across industries such as oil and gas, power generation, and water infrastructure. For technical specifications, custom configurations, or pricing, contact Ladhani Metal Corporation today.

Send Message