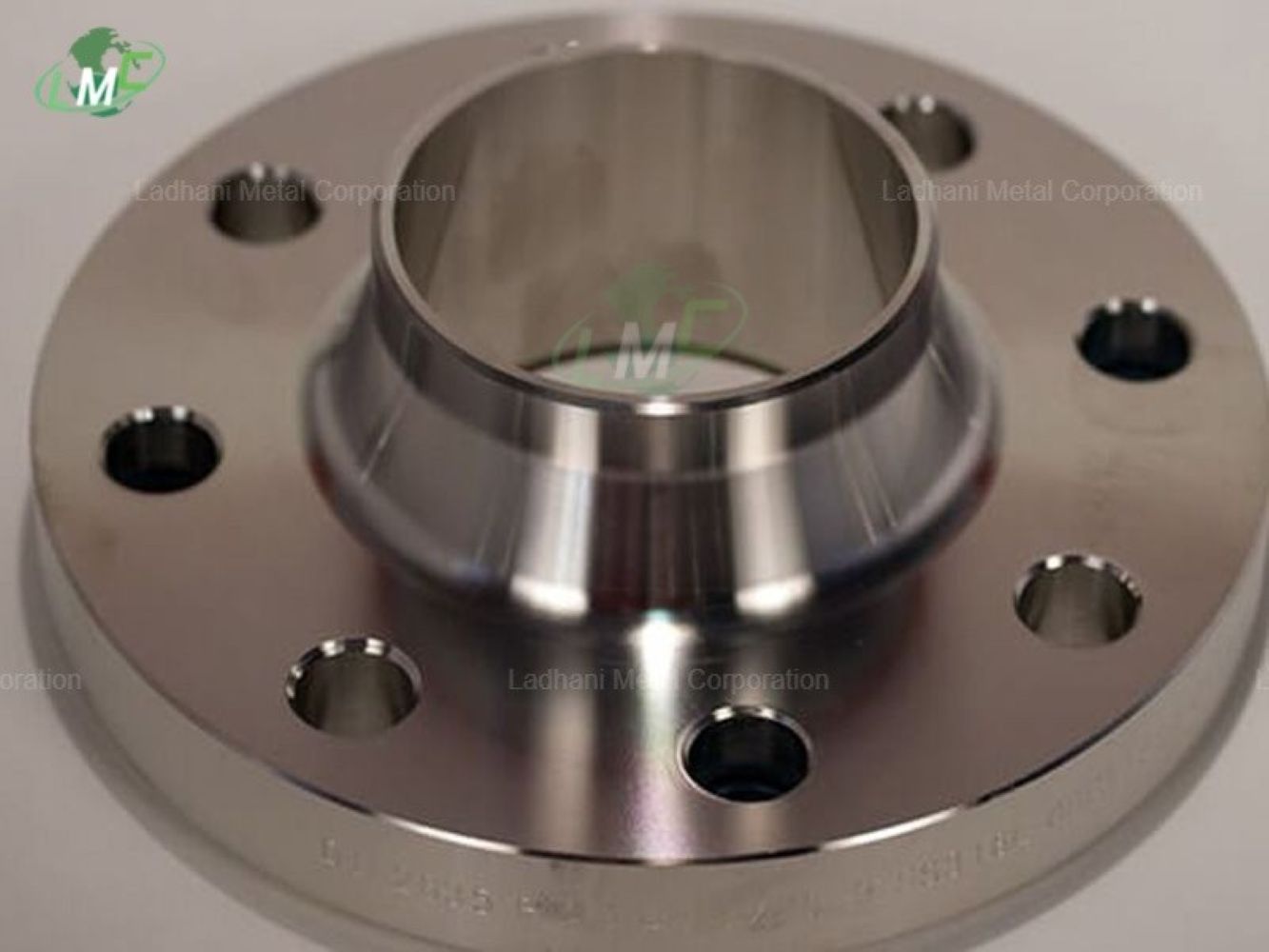

DIN 2627 stainless steel flanges PN 400 are precision-engineered blind flanges manufactured according to the DIN 2627 standard. Designed to withstand ultra-high-pressure conditions up to 400 bar (5800 psi), these flanges are used to terminate or isolate piping systems safely and effectively. Fabricated from high-grade stainless steels, including 304, 316, and 321, these blind flanges provide superior mechanical strength, corrosion resistance, and long service life in aggressive industrial environments. Ladhani Metal Corporation is a globally recognized manufacturer and exporter of stainless steel flanges. Our DIN 2627 PN 400 blind flanges are widely trusted in sectors such as oil and gas, chemical processing, marine, energy, and high-pressure utility systems for their durability, quality, and performance under extreme conditions. Pressure Rating: • PN 400 (400 bar / 5800 psi): Suitable for high-pressure pipelines and critical systems where absolute sealing and structural integrity are required. Flange Type: • Blind Flanges Solid, non-bored flanges used to block pipeline ends or vessel nozzles. These flanges are essential for system isolation during maintenance, testing, or future expansions. • Flat Face (FF) Flanges Flat face flanges are designed to mate with flat gaskets and flat-faced components. They provide even gasket compression and are ideal when used with cast iron or brittle materials to avoid flange distortion. Stainless Steel Grades and Full Composition: Stainless Steel 304 • Chromium (Cr): 18.0 – 20.0% • Nickel (Ni): 8.0 – 10.5% • Carbon (C): ≤ 0.08% (304), ≤ 0.03% (304L) • Manganese (Mn): ≤ 2.0% • Silicon (Si): ≤ 1.0% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.03% • Iron (Fe): Balance Applications: Excellent general corrosion resistance. Commonly used in food processing, water systems, and chemical equipment. Stainless Steel 316 • Chromium (Cr): 16.0 – 18.0% • Nickel (Ni): 10.0 – 14.0% • Molybdenum (Mo): 2.0 – 3.0% • Carbon (C): ≤ 0.08% (316), ≤ 0.03% (316L) • Manganese (Mn): ≤ 2.0% • Silicon (Si): ≤ 1.0% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.03% • Iron (Fe): Balance Applications: Enhanced resistance to chlorides and acidic environments. Ideal for marine, pharmaceutical, and chemical processing. Stainless Steel 321 • Chromium (Cr): 17.0 – 19.0% • Nickel (Ni): 9.0 – 12.0% • Titanium (Ti): ≥ 5 × C (typically 0.20 – 0.70%) • Carbon (C): ≤ 0.08% • Manganese (Mn): ≤ 2.0% • Silicon (Si): ≤ 1.0% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.03% • Iron (Fe): Balance Applications: 321 stainless steel is stabilized with titanium, providing excellent resistance to intergranular corrosion after welding and high-temperature exposure. Commonly used in thermal processing, aerospace, and exhaust systems. Applications of DIN 2627 Stainless Steel Flanges PN 400: • Oil and Gas Industry Used in upstream and downstream systems, where high pressure and harsh chemicals are common. • Chemical and Petrochemical Plants Ideal for isolating high-pressure lines carrying corrosive or reactive chemicals. • Marine and Offshore Engineering Suitable for saltwater-exposed piping, ballast systems, and underwater applications requiring corrosion resistance. • Power Generation Applied in steam, nuclear, and thermal plants for sealing pressurized piping and vessel systems. • Aerospace and High-Temperature Systems 321-grade blind flanges are used in systems exposed to elevated temperatures and thermal cycling. • Water Treatment and Desalination Withstands chloride-induced corrosion in high-pressure brine and filtration lines. Key Features: • Manufactured to DIN 2627 specifications • PN 400 pressure rating for extreme pressure performance • Blind flange design ideal for system isolation and termination • Available in stainless steel grades 304, 304L, 316, 316L, and 321 • Flat face type for even gasket compression and sealing integrity • Superior corrosion resistance and mechanical strength • Suitable for aggressive chemical, marine, and high-temperature environments • Custom sizes, surface finishes, and pressure classes available upon request Conclusion: DIN 2627 Stainless Steel Flanges PN 400 by Ladhani Metal Corporation are designed for maximum performance in high-pressure, corrosive, and high-temperature environments. With material options including 304, 316, and titanium-stabilized 321 stainless steel, these blind flanges offer flexibility, reliability, and long-term service life across critical industries. Contact Ladhani Metal Corporation today for technical assistance, specifications, or custom flange solutions.

Send Message