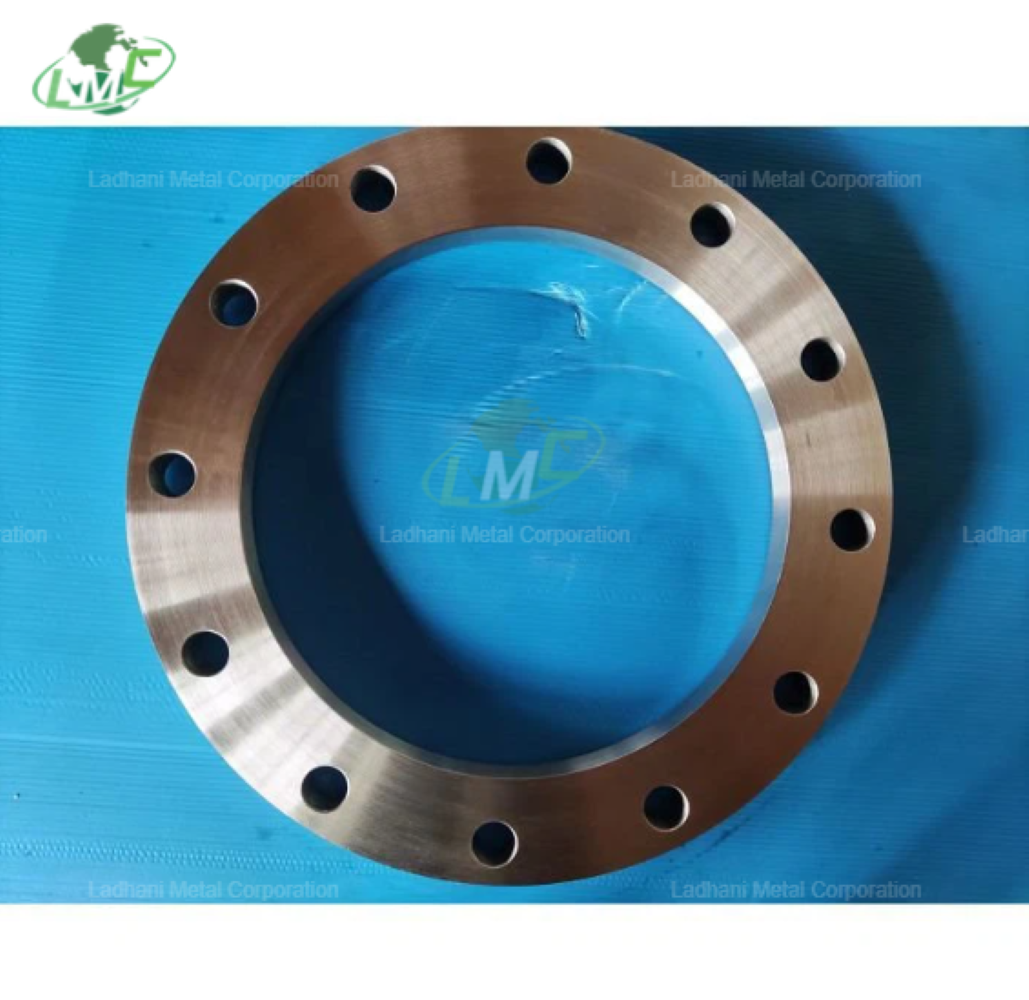

Monel Flanges

DIN 2573 Monel Flanges PN 6 are premium-quality, low-pressure plate flanges crafted from Monel alloys, specifically engineered for systems that operate in highly corrosive and aggressive environments. Manufactured in accordance with DIN 2573 standards, these flanges offer excellent resistance to seawater, acids, and high-temperature conditions, making them an ideal choice for industries such as marine engineering, chemical processing, oil and gas, and power generation. The exceptional properties of Monel alloys ensure durability and reliability in applications requiring strong resistance to pitting, crevice corrosion, and stress corrosion cracking.

Ladhani Metal Corporation is a trusted manufacturer and global supplier of Monel alloy flanges, delivering high-quality products that meet rigorous international standards. The DIN 2573 flange design ensures easy installation and provides a secure, leak-free connection, even in low-pressure, harsh environments.

Pressure Rating:

• PN 6 (6 bar / 87 psi): Designed for low-pressure applications in corrosive and high-temperature environments where Monel’s strength and resistance to corrosion are critical for long-term performance.

Flange Types:

• Plate Flanges

Flat flanges ideal for bolted connections in piping systems where gasket sealing is required, providing secure, leak-free operation in low-pressure systems.

• Flat Face (FF) Flanges

Used with flat gaskets and mating surfaces, ensuring uniform contact and load distribution, particularly when joining with non-metallic components or cast iron systems.

• Slip-On Flanges

These flanges slip over the pipe, providing easy alignment and easy-to-weld connections, ideal for low-pressure applications with moderate pressure fluctuations.

• Custom-Machined Flanges

Tailored to meet specific dimensional and material requirements, available in various sizes, grades, and face finishes to suit the needs of custom applications.

Monel Grades and Composition:

Monel 400 (UNS N04400)

Composition:

• Nickel (Ni): 63.0 – 70.0%

• Copper (Cu): 28.0 – 34.0%

• Iron (Fe): ≤ 2.5%

• Manganese (Mn), Silicon (Si), Carbon (C): Trace amounts

Applications:

Monel 400 is widely used in marine environments, chemical processing, and heat exchangers, where it is subjected to both high temperatures and exposure to saltwater or acids. Its superior resistance to corrosion and oxidation makes it a preferred material in demanding applications like pumps, valves, and marine piping systems.

Monel K-500 (UNS N05500)

Composition:

• Nickel (Ni): 63.0 – 70.0%

• Copper (Cu): 27.0 – 33.0%

• Aluminum (Al): 2.3 – 3.2%

• Titanium (Ti): 0.35 – 0.85%

• Iron (Fe): ≤ 2.5%

Applications:

Monel K-500 offers higher strength and hardness compared to Monel 400, making it suitable for applications in oil and gas extraction, marine industries, and aerospace systems, where both corrosion resistance and high mechanical properties are required.

Applications of DIN 2573 Monel Flanges:

• Chemical and Petrochemical Plants:

Monel flanges are ideal for use in chemical reactors, exchangers, and pipelines handling aggressive chemicals like sulfuric acid, hydrochloric acid, and caustics.

• Marine and Offshore Engineering:

Highly resistant to seawater corrosion, Monel flanges are used extensively in marine piping systems, offshore oil rigs, and shipbuilding applications where exposure to saltwater and harsh weather conditions is frequent.

• Oil and Gas Industry:

Monel flanges are often used in production platforms, refineries, and pipelines exposed to brine and acidic substances, offering both strength and resistance to corrosion under high-stress conditions.

• Power Generation:

Used in systems handling high-temperature steam and corrosive environments, Monel flanges provide reliable service for high-performance power plant components.

• Desalination and Water Treatment:

With their corrosion resistance to saline environments, Monel flanges are also ideal for seawater desalination plants and water treatment facilities.

Key Features:

• Manufactured according to DIN 2573 standards

• Rated for PN 6 low-pressure systems, with exceptional resistance to corrosion

• Outstanding performance in highly corrosive, high-temperature environments

• Available in Monel 400, Monel K-500, and other Monel alloys

• High strength-to-weight ratio for reliable long-term performance

• Suitable for marine, offshore, chemical, and power generation applications

• Available with custom drilling, surface finishes, and flange faces

Conclusion:

DIN 2573 Monel Flanges PN 6 from Ladhani Metal Corporation provide unmatched durability, corrosion resistance, and performance in low-pressure applications exposed to challenging chemical, thermal, and environmental conditions. For custom dimensions, material selections, or technical support, contact Ladhani Metal Corporation today.

Price: 0 |

Payment Type: |

Available: False |

COD Available: False |

KYC Status: FAILED

Send Message