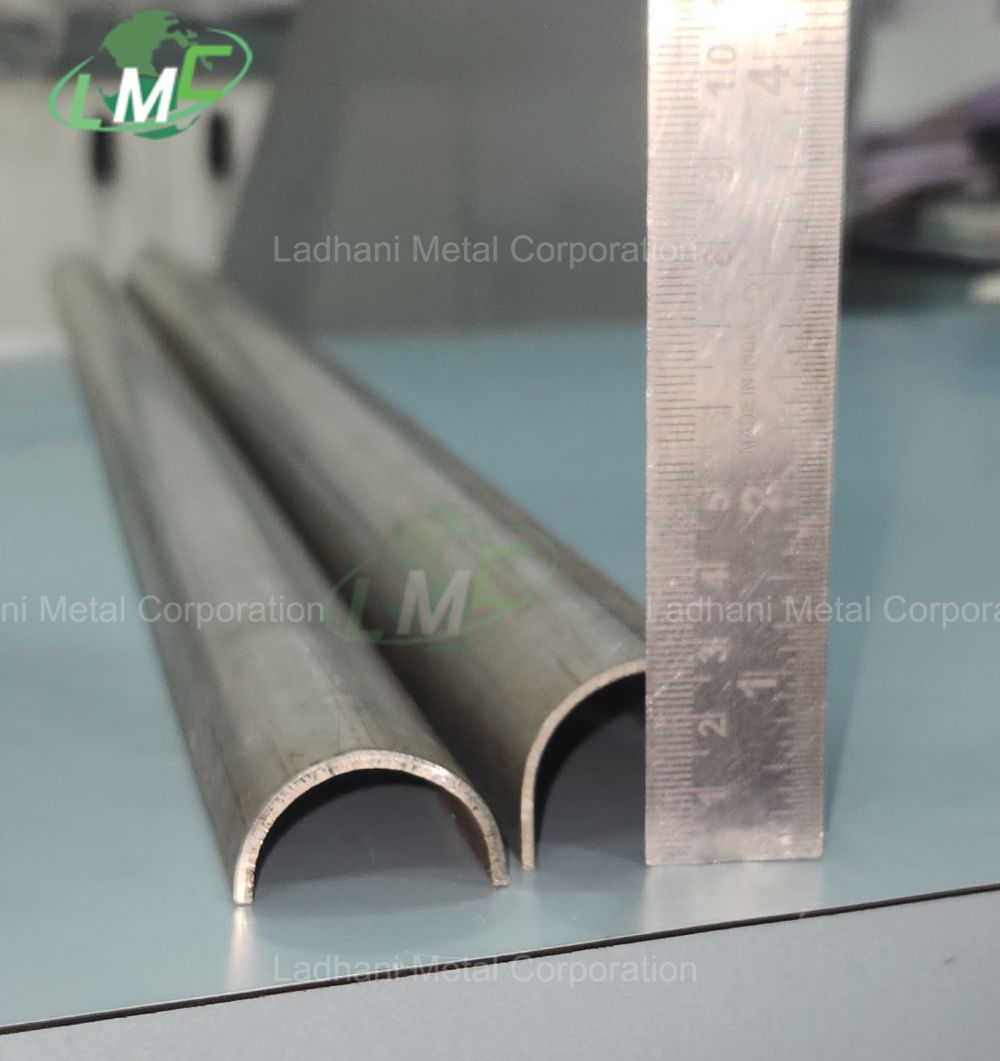

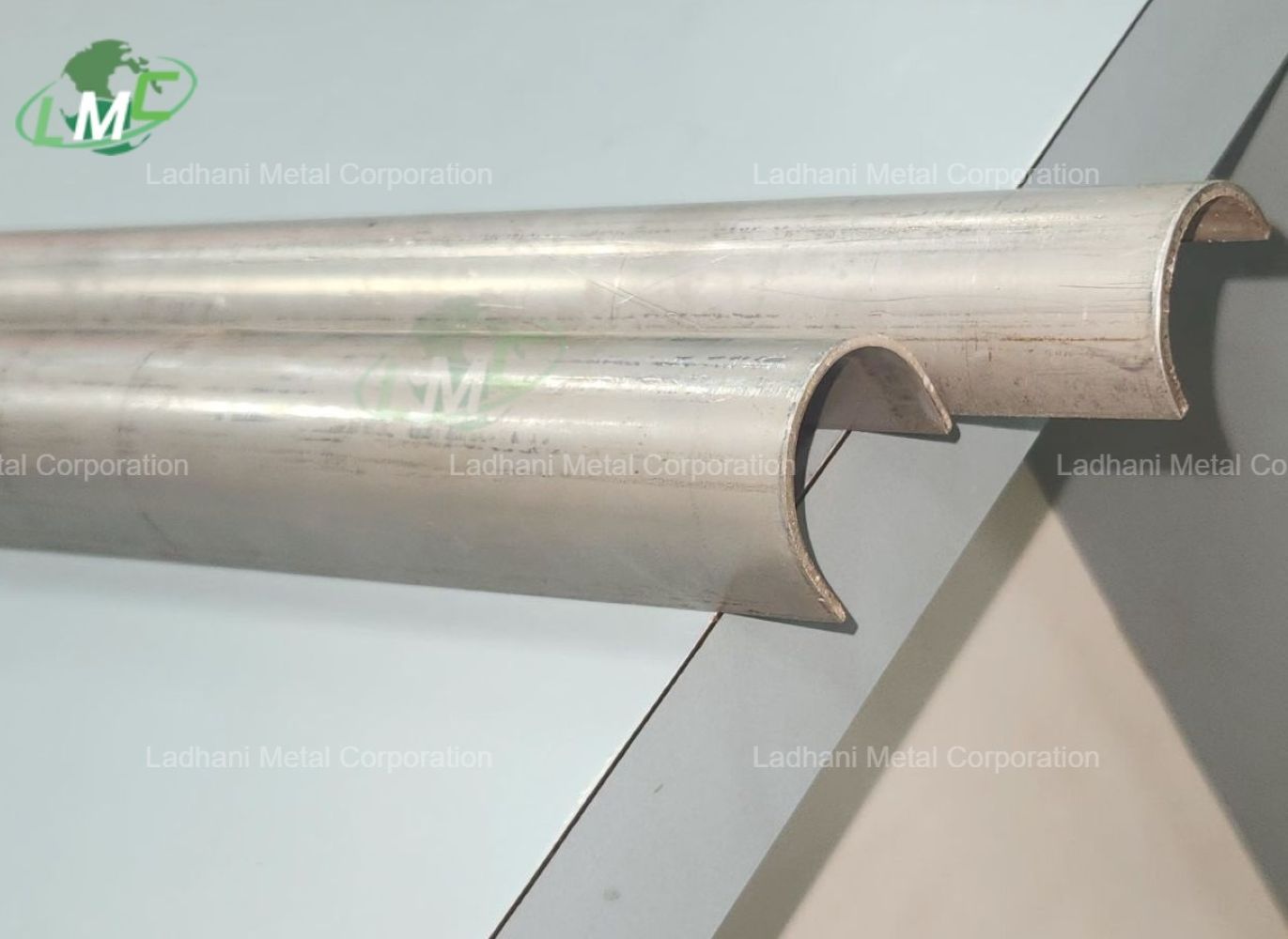

1Cr20Ni14Si2 Half Round Straight Tube Shield The 1Cr20Ni14Si2 Half Round Straight Tube Shield is formed in a semi-cylindrical shape to shield the outer surface of straight tubes from ash erosion, thermal scaling, and high-velocity gas flow. These shields are crucial for preventing tube wall thinning, cracking, and performance deterioration in systems operating under frequent temperature fluctuations or corrosive gas atmospheres. Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of 1Cr20Ni14Si2 Half Round Straight Tube Shields, delivering dimensionally accurate and corrosion-resistant solutions for demanding industrial operations. Material Grade 1Cr20Ni14Si2 – A heat-resistant stainless steel alloy with high chromium and nickel content, enhanced with silicon for improved oxidation resistance and thermal strength. Chemical Composition of 1Cr20Ni14Si2 • Carbon (C): ≤ 0.10% • Silicon (Si): 1.50 – 2.50% • Manganese (Mn): ≤ 1.50% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Chromium (Cr): 19.0 – 21.0% • Nickel (Ni): 13.0 – 15.0% • Iron (Fe): Balance Uses • Straight tube shielding in waste heat recovery boilers and reformers • Surface protection in convection zones of fired heaters and steam boilers • Tube erosion control in thermal oxidizers and flue gas paths • High-temperature corrosion resistance in petrochemical reactors • Applied in furnace chambers, radiant coils, and syngas coolers Features • Outstanding oxidation and scaling resistance at elevated temperatures • High strength under thermal cycling and mechanical stress • Protects against ash and gas erosion in boiler and furnace systems • Custom-fit shields available in various lengths and thicknesses • Suitable for banding, welding, or clamping installation methods • Enhances tube life and reduces maintenance frequency Applications • power generation – Boilers, WHRBs, and economizers in thermal plants • chemical and fertilizer industry – Reformers, converters, and synthesis gas lines • metallurgy – Furnace tube protection in steel and heat treatment facilities • refineries – Process heater protection in crude and catalytic reformers • incineration – Combustion tube protection in waste-to-energy plants Conclusion 1Cr20Ni14Si2 Half Round Straight Tube Shields from Ladhani Metal Corporation are engineered to perform under high thermal loads and corrosive conditions. Their robust design and material strength make them ideal for protecting straight tubes in critical heat transfer systems, extending service life and maintaining operational efficiency. For detailed specifications, custom orders, or inquiries, contact Ladhani Metal Corporation. #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #halftubeshield #utypehalftubeshield #tubeshieldexporter #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Salem #Erode #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Hassan #Cuttack #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Gaya #Muzaffarpur

Send Message