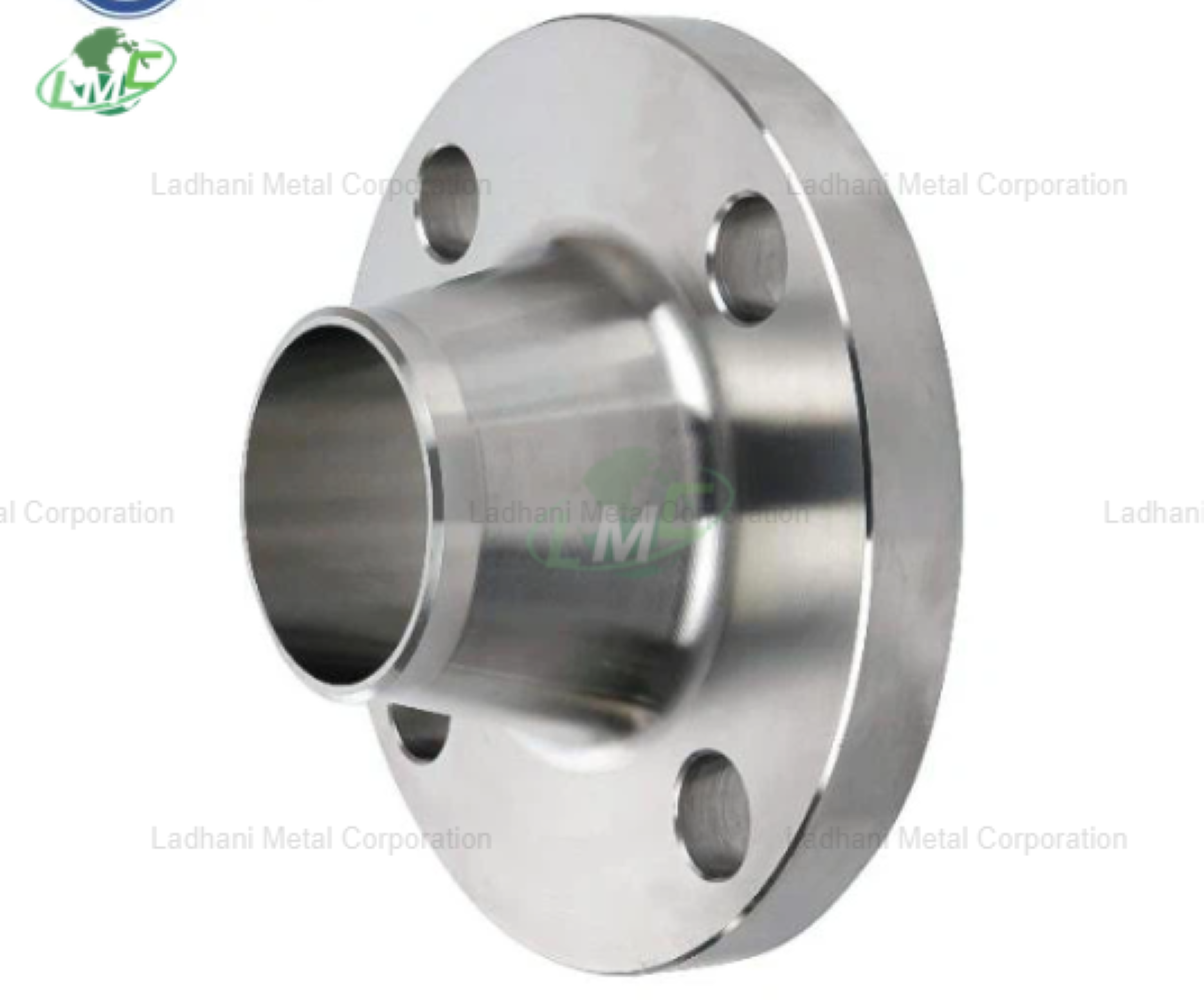

DIN 2634 super duplex steel flanges PN 25 are high-performance weld neck flanges designed in accordance with the DIN 2634 standard. These flanges are engineered for high-pressure systems operating up to 25 bar (362 psi) and are manufactured from premium super duplex stainless steel grades. Known for their superior strength, excellent corrosion resistance, and enhanced resistance to stress corrosion cracking and pitting, super duplex flanges are ideally suited for demanding industrial environments. Their robust mechanical properties make them a reliable choice for aggressive service conditions and high-pressure applications. Ladhani Metal Corporation is a global leader in the manufacturing and supply of super duplex steel flanges. With advanced production facilities, precision engineering capabilities, and rigorous quality assurance practices, the company ensures that each flange meets the highest standards of safety, durability, and performance under extreme conditions. Pressure Rating: • PN 25 (25 bar / 362 psi): Designed for systems requiring high strength and exceptional corrosion resistance under elevated pressure conditions. Flange Type: • Weld Neck Flanges Featuring a tapered hub design, weld neck flanges deliver optimal stress distribution and secure, leak-free connections in systems exposed to thermal and mechanical loading. • Flat Face (FF) Flanges Recommended for use with softer gasket materials or systems incorporating cast iron components, flat face flanges provide uniform gasket compression and reliable sealing. Super Duplex Steel Grades and Typical Composition: Super Duplex Steel (UNS S32750 / S32760) – Ferritic-Austenitic Stainless Steel • Chromium (Cr): 24.0 – 26.0% • Nickel (Ni): 6.0 – 8.0% • Molybdenum (Mo): 3.0 – 5.0% • Nitrogen (N): 0.2 – 0.3% • Iron (Fe): Balance Applications: Widely used in environments where high strength, corrosion resistance, and resistance to chloride-induced stress corrosion cracking are essential, such as offshore platforms, chemical plants, and desalination facilities. Applications of DIN 2634 Super Duplex Steel Flanges PN 25: • Offshore and Subsea Installations Withstand chloride-rich marine environments, offering long-term durability and resistance to seawater corrosion. • Chemical and Petrochemical Processing Suitable for handling aggressive chemicals, acids, and solvents under high pressure and temperature conditions. • Desalination and Water Treatment Plants Perform reliably in saline and brine-rich environments with superior resistance to pitting and crevice corrosion. • Power Generation and Heat Exchangers Offer excellent performance in high-temperature, high-pressure applications requiring strength and corrosion protection. • Pulp and Paper Industry Operate effectively in harsh chemical environments including bleach and acidic processing streams. Key Features: • Manufactured to DIN 2634 specifications for dimensional accuracy and pressure handling • PN 25 pressure class supports high-performance applications • Superior resistance to localized corrosion including pitting and stress corrosion cracking • High strength-to-weight ratio and excellent mechanical properties • Weld neck design ensures structural integrity and resistance to fatigue • Available in both UNS S32750 and S32760 super duplex grades • Customizable in size, pressure class, and surface finish upon request Conclusion: DIN 2634 super duplex steel flanges PN 25 from Ladhani Metal Corporation are engineered to deliver top-tier performance in environments where mechanical strength and corrosion resistance are non-negotiable. Their robust construction and excellent durability make them ideal for marine, chemical, and industrial applications operating under high pressure. For detailed specifications, project consultations, or a custom quote, contact Ladhani Metal Corporation today.

Send Message