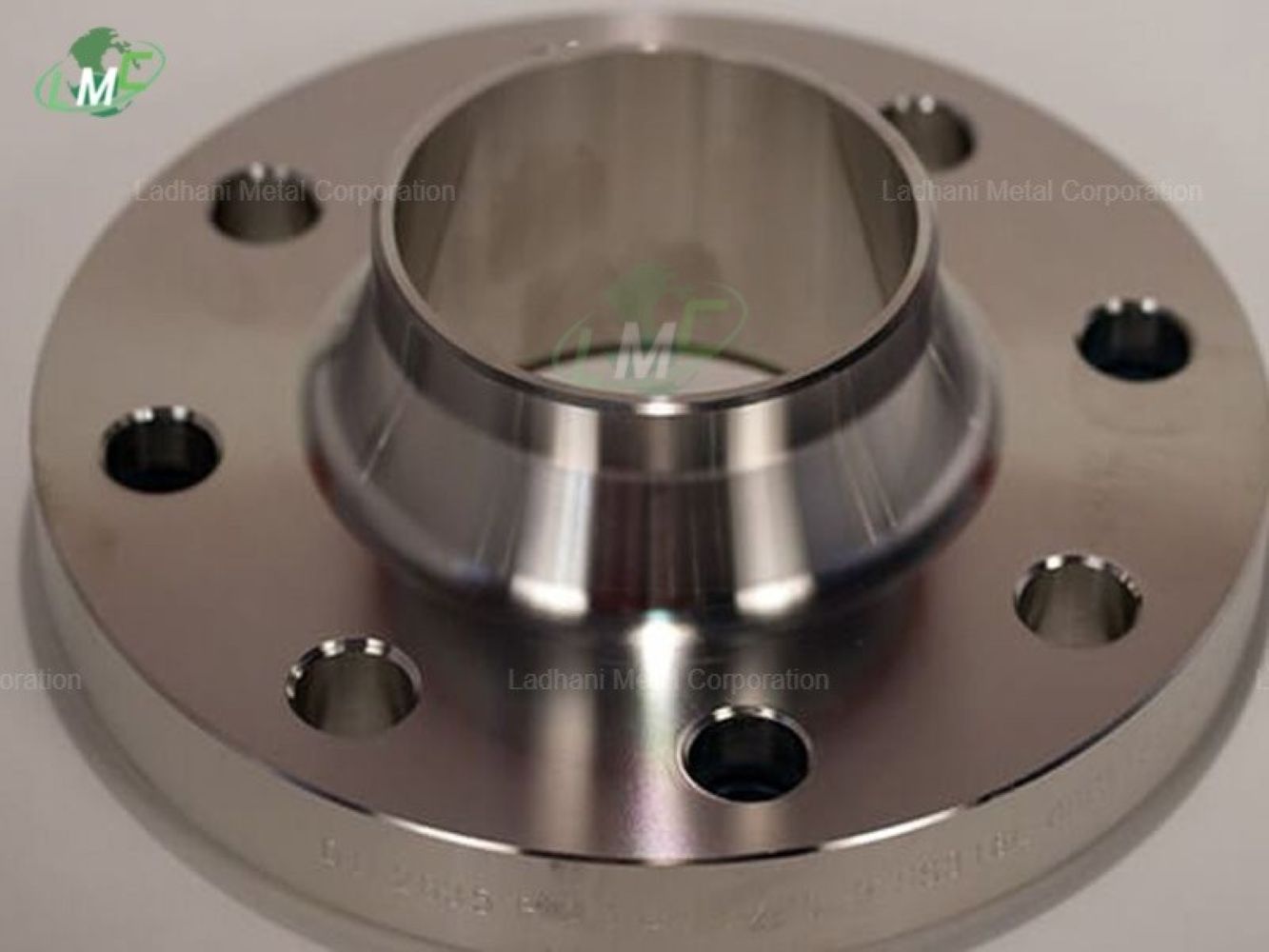

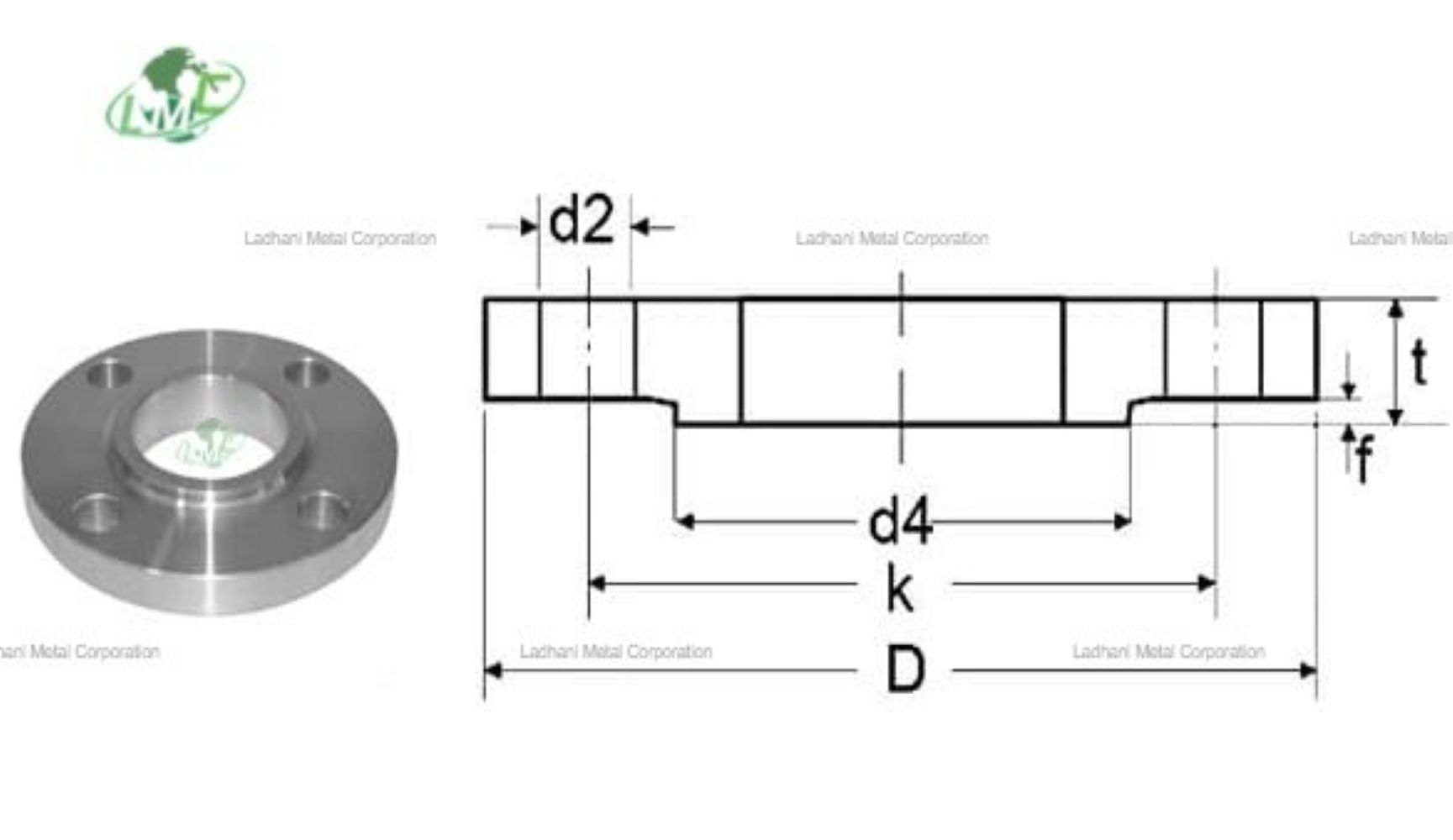

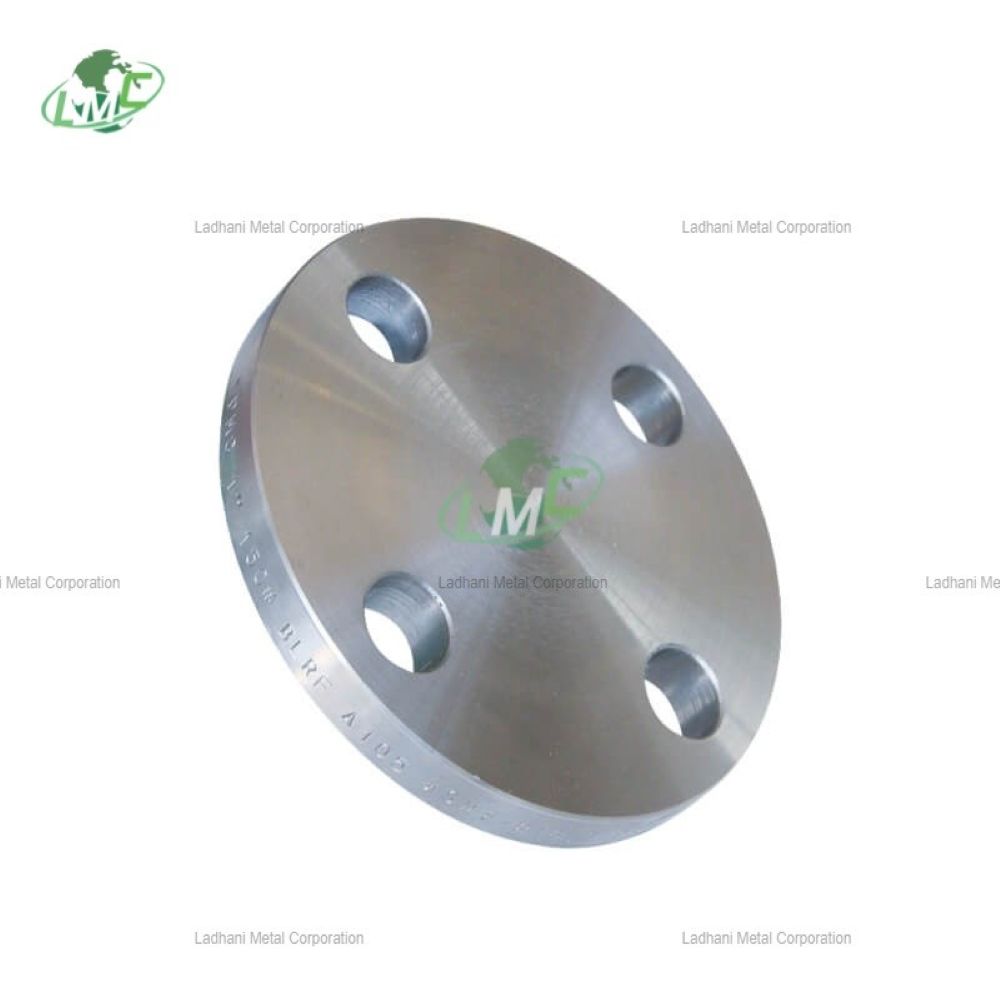

DIN 2627 Duplex Steel flanges PN 400 are high-integrity blind flanges engineered for ultra-high-pressure systems where enhanced corrosion resistance, mechanical strength, and stress corrosion cracking resistance are crucial. These flanges are manufactured in compliance with the DIN 2627 standard and are used to seal the ends of piping systems operating under extreme conditions involving high pressure, temperature fluctuations, and aggressive media such as chlorides or acidic compounds. The PN 400 rating (400 bar / 5800 psi) ensures these flanges are suitable for the most demanding environments. Made from Duplex and Super Duplex stainless steels—such as Duplex 2205 (UNS S31803/S32205) and Super Duplex 2507 (UNS S32750)—they offer a unique combination of austenitic and ferritic microstructures, providing exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. Pressure Rating: • PN 400 (400 bar / 5800 psi): Designed for use in high-pressure systems where superior strength and corrosion resistance are required. Flange Type: • Blind Flanges Flat, solid flanges without a bore, used to seal off pipeline ends or nozzles for isolation, pressure testing, or future expansion. • Flat Face (FF) Flanges Feature a flat sealing surface suitable for use with full-face gaskets and flat-faced mating components to ensure uniform sealing under high-pressure conditions. Duplex Steel Grades and Composition: Duplex 2205 (UNS S31803 / S32205) • Chromium (Cr): 21 – 23% • Nickel (Ni): 4.5 – 6.5% • Molybdenum (Mo): 2.5 – 3.5% • Nitrogen (N): 0.08 – 0.2% • Iron (Fe): Balance Applications: High strength and excellent resistance to chloride-induced stress corrosion and pitting. Commonly used in chemical tanks, pipelines, and pressure vessels. Applications of DIN 2627 Duplex Steel Flanges PN 400: • Offshore and Subsea Oil & Gas Installations Withstand high pressure, chloride-rich environments, and dynamic loading in risers, manifolds, and subsea pipelines. • Desalination Plants and Seawater Systems Exceptional resistance to chloride-induced corrosion makes them ideal for seawater intake and brine discharge lines. • Chemical and Petrochemical Plants Used in corrosive process lines involving acids, solvents, and high-temperature hydrocarbons. • Pulp and Paper Industry Ideal for chemical recovery systems and chlorine dioxide bleaching where both corrosion and strength are essential. • Heat Exchangers and Pressure Vessels High strength and thermal fatigue resistance under cyclic temperature and pressure changes. • Power Generation and Nuclear Systems Effective in high-pressure steam and cooling systems where corrosion resistance and mechanical integrity are mandatory. Key Features: • Compliant with DIN 2627 specifications • PN 400 pressure rating for ultra-high-pressure applications • Blind flange configuration ensures secure system isolation • Flat face design supports full-face gasket usage for optimal sealing • Available in Duplex 2205 and Super Duplex 2507 • Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking • High mechanical strength with good weldability and fatigue resistance • Used across offshore, petrochemical, desalination, and energy sectors • Custom dimensions, materials, and finishes available upon request Conclusion: DIN 2627 Duplex Steel Flanges PN 400 from Ladhani Metal Corporation deliver unmatched reliability and performance in the harshest operating conditions. Whether used in high-pressure offshore pipelines or corrosive chemical systems, these flanges offer long-term sealing, structural integrity, and corrosion resistance. Reach out to Ladhani Metal Corporation for technical assistance, material selection, or customized Duplex flange solutions tailored to your operational demands.

Send Message