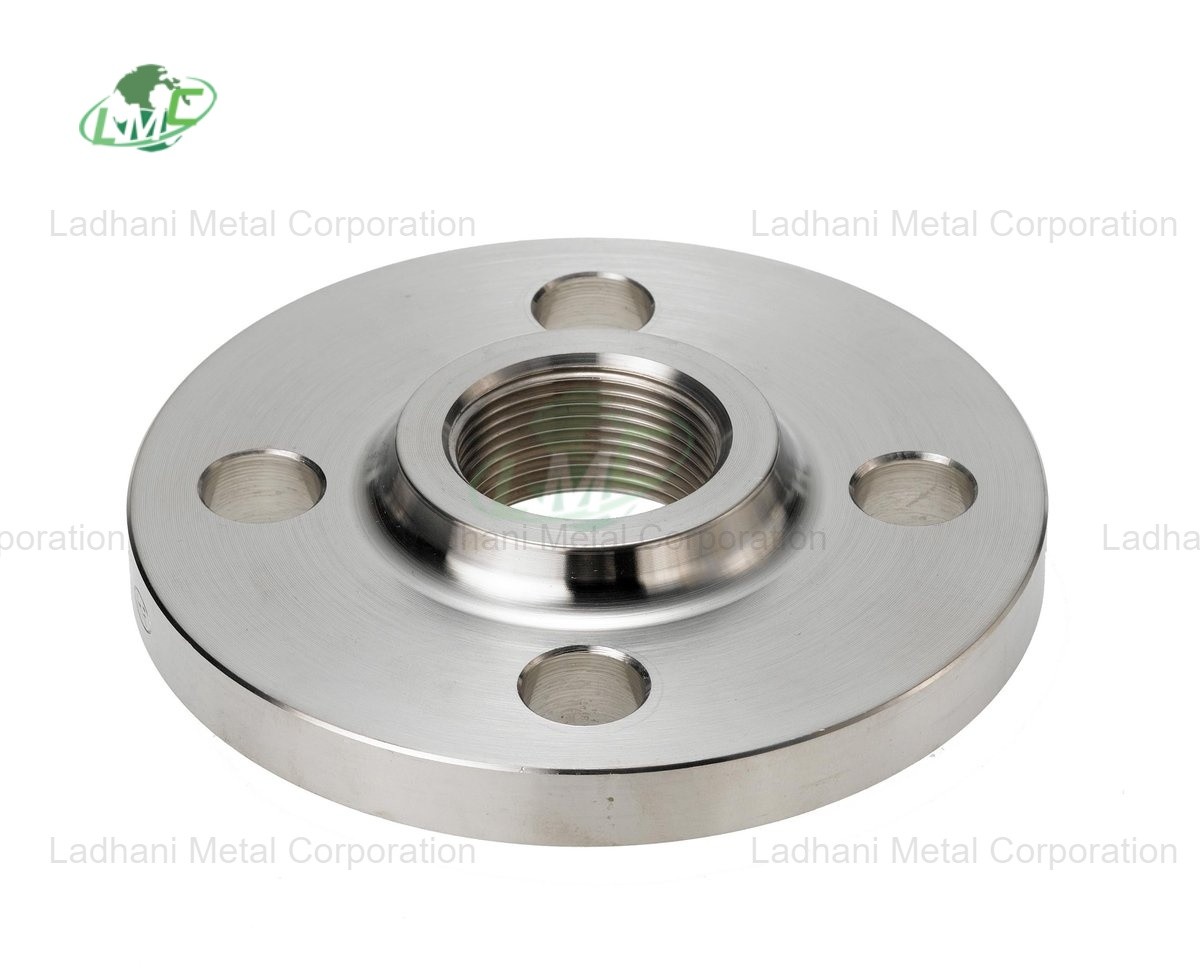

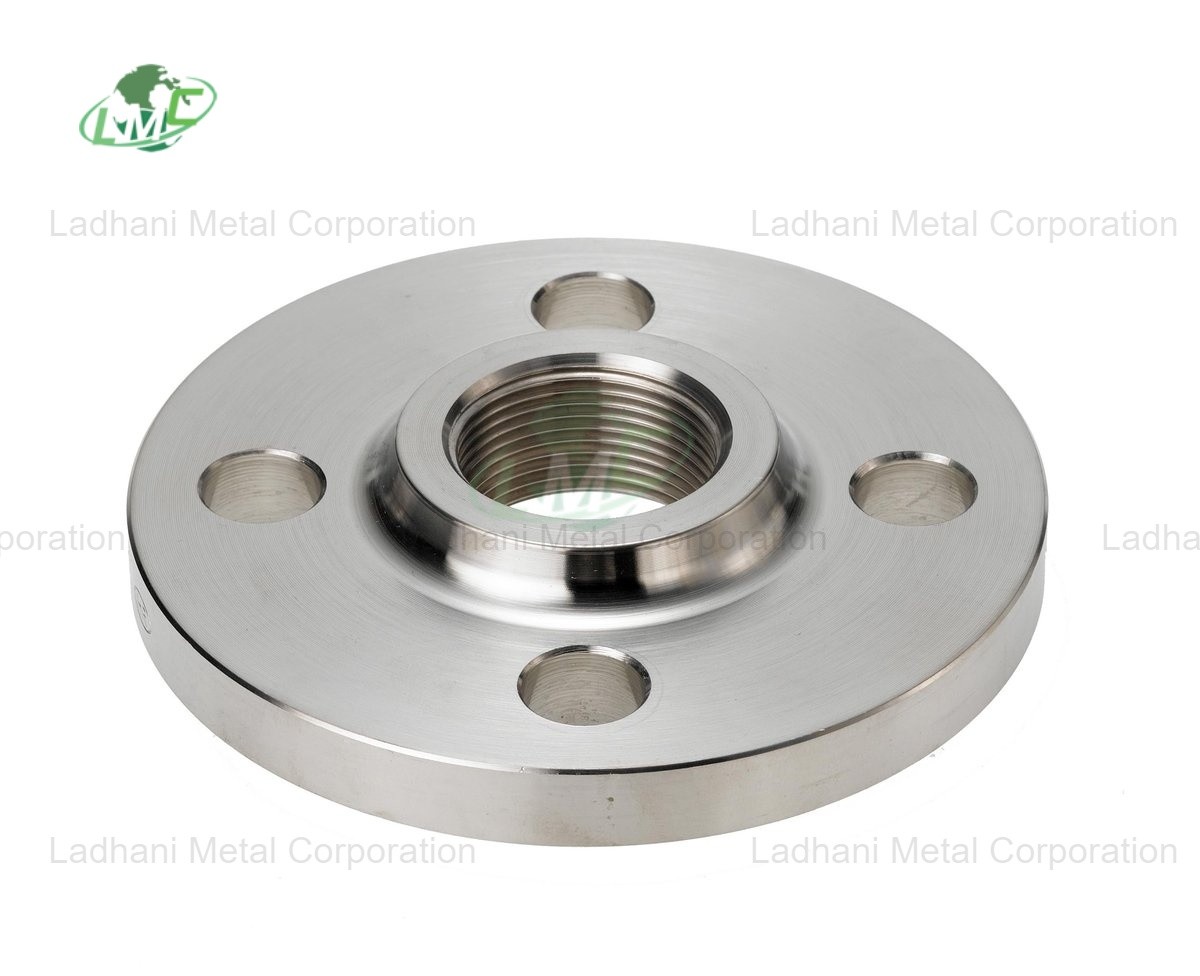

Duplex Steel Flanges

DIN 2569 Duplex Steel Flanges PN 100 are precision-engineered welding neck flanges manufactured from high-performance duplex stainless steel, designed to ensure superior strength, corrosion resistance, and reliability in high-pressure and aggressive industrial environments. Built to DIN 2569 standards, these flanges offer excellent mechanical strength, stress corrosion cracking resistance, and thermal stability, making them ideal for use in industries such as oil and gas, offshore platforms, petrochemical, chemical processing, and marine engineering.

Ladhani Metal Corporation is a reputable manufacturer and exporter of duplex steel flanges, providing products that conform to stringent global standards. The welding neck design allows for permanent and high-integrity pipe connections, making these flanges particularly suitable for applications subject to pressure fluctuations, corrosive media, and thermal cycling.

Pressure Rating:

• PN 100 (100 bar / 1450 psi): Specifically designed for high-pressure systems that demand robust sealing, mechanical resilience, and corrosion resistance in chemically aggressive environments.

Flange Types:

• Welding Neck Flanges

Provide a tapered hub for stress distribution, ideal for high-pressure and corrosive piping systems.

• Raised Face (RF) Flanges

Facilitates effective gasket compression and sealing under elevated pressure and temperature.

• Flat Face (FF) Flanges

Used for connections with flat-faced components or non-metallic sealing materials.

• Forged Welding Neck Flanges

Offer enhanced strength, dimensional precision, and pressure resistance.

• Custom-Machined Flanges

Available in a wide range of sizes, pressure classes, and duplex steel grades to meet specific project requirements.

Duplex Steel Grades and Composition:

1. ASTM A182 F51 (UNS S31803)

Composition:

• Chromium (Cr): 21.0–23.0%

• Nickel (Ni): 4.5–6.5%

• Molybdenum (Mo): 2.5–3.5%

• Nitrogen (N): 0.10–0.22%

• Manganese (Mn): ≤ 2.00%

• Carbon (C): ≤ 0.030%

• Phosphorus (P): ≤ 0.035%

• Sulfur (S): ≤ 0.020%

Applications:

Widely used in chemical plants, desalination equipment, marine structures, and oil and gas platforms due to its excellent pitting and crevice corrosion resistance.

2. ASTM A182 F53 (UNS S32750)

Composition:

• Chromium (Cr): 24.0–26.0%

• Nickel (Ni): 6.0–8.0%

• Molybdenum (Mo): 3.0–5.0%

• Nitrogen (N): 0.24–0.32%

• Manganese (Mn): ≤ 1.20%

• Carbon (C): ≤ 0.030%

• Phosphorus (P): ≤ 0.035%

• Sulfur (S): ≤ 0.020%

Applications:

Ideal for applications in offshore platforms, chemical tankers, and seawater systems, where high chloride resistance and strength are essential.

3. ASTM A182 F55 (UNS S32760)

Composition:

• Chromium (Cr): 24.0–26.0%

• Nickel (Ni): 6.0–8.0%

• Molybdenum (Mo): 3.0–4.0%

• Copper (Cu): 0.5–1.0%

• Tungsten (W): 0.5–1.0%

• Nitrogen (N): 0.20–0.30%

• Carbon (C): ≤ 0.030%

• Manganese (Mn): ≤ 1.00%

Applications:

Used in demanding environments such as chemical processing, seawater handling systems, pulp and paper industries, and aggressive brine systems.

Applications of DIN 2569 Duplex Steel Flanges:

• Oil and Gas Pipelines:

Used in high-pressure and corrosive media transport systems such as offshore and subsea pipelines.

• Offshore and Marine Engineering:

Installed in seawater cooling, ballast, and firefighting systems due to chloride resistance.

• Petrochemical and Chemical Plants:

Applied in aggressive media handling, reactors, and process lines.

• Desalination and Water Treatment:

Used in brine concentrators, high-pressure RO systems, and intake piping.

• Pulp and Paper Industry:

Employed in bleach plant and digester systems under high stress and chemical exposure.

Key Features:

• Manufactured to DIN 2569 standard

• Available in PN 100 pressure rating

• Excellent corrosion resistance and mechanical performance

• High strength-to-weight ratio

• Resistant to pitting, crevice corrosion, and stress corrosion cracking

• Supplied with test certificates, quality assurance documents, and traceability

• Optional surface finishes available, including pickling, passivation, and shot blasting

Conclusion:

DIN 2569 Duplex Steel Flanges PN 100 from Ladhani Metal Corporation are engineered to deliver superior strength, durability, and corrosion resistance in challenging industrial environments. Suitable for a wide range of applications across offshore, petrochemical, and marine sectors, these flanges are available in customizable sizes and duplex material grades. For detailed specifications, bulk inquiries, or technical support, contact Ladhani Metal Corporation today.

Price: 0 |

Payment Type: |

Available: False |

COD Available: False |

KYC Status: FAILED

Send Message