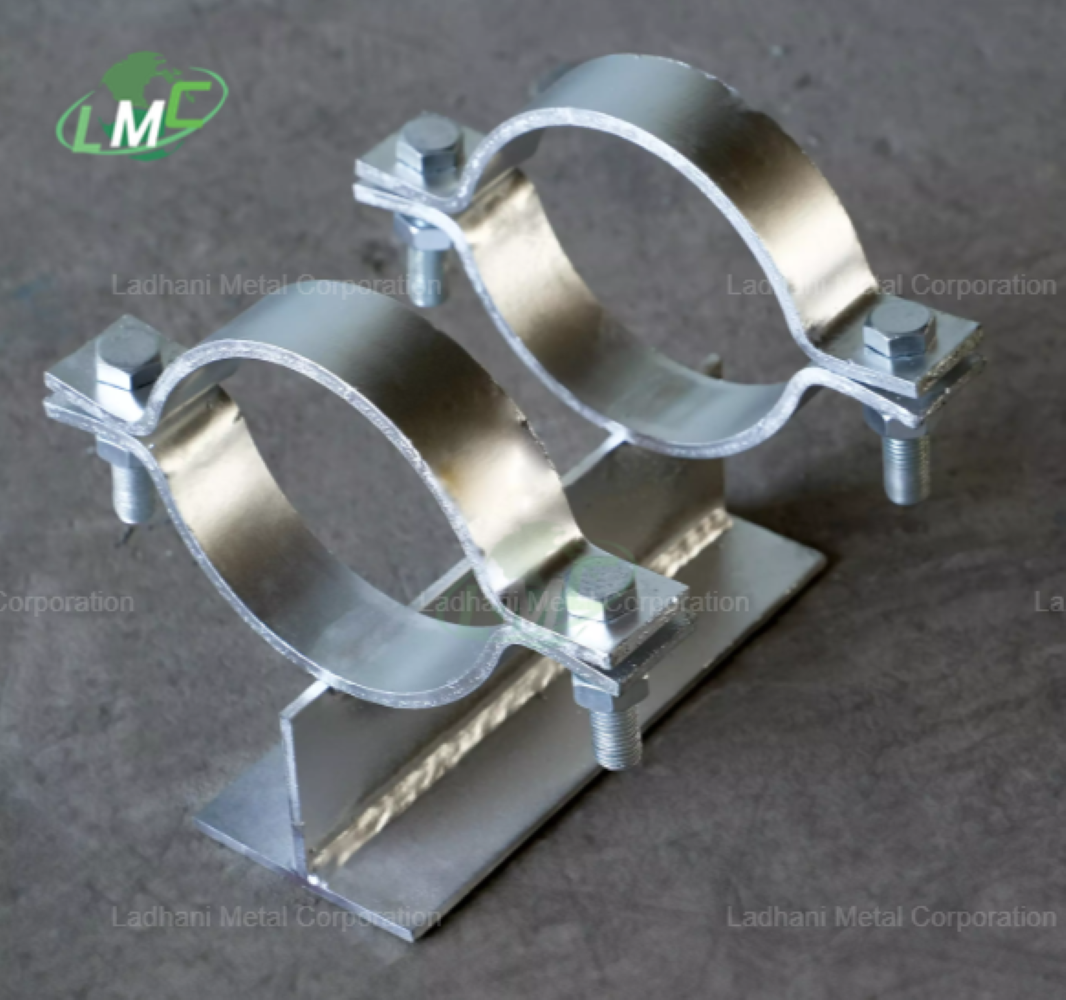

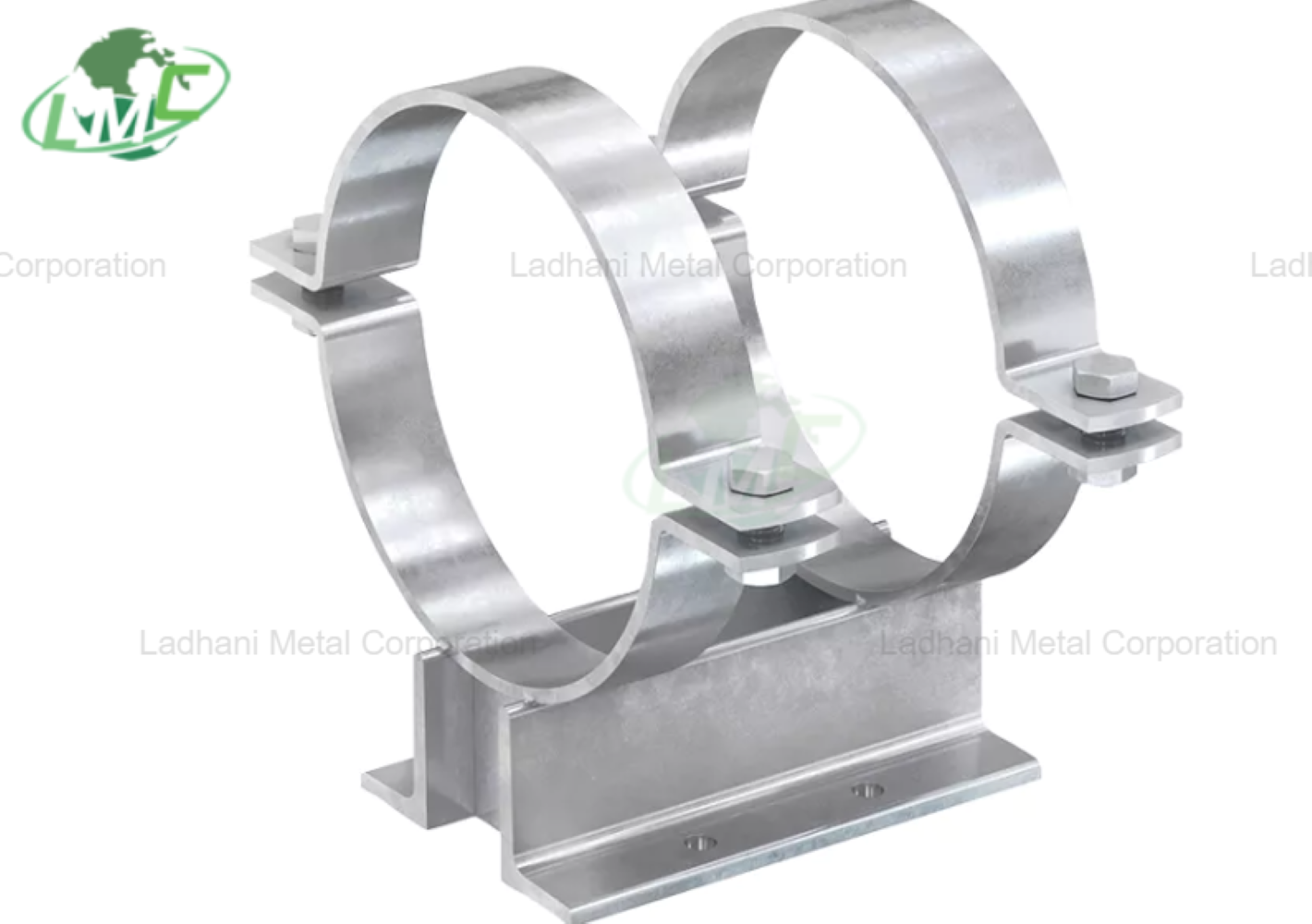

Ladhani Metal Corporation offers SS Insulated Pipe Shoe Clamps designed to support and secure pipelines while maintaining thermal insulation integrity. These clamps are specially engineered with insulation material between the pipe and the shoe, ensuring minimal heat transfer and preventing energy loss in high-temperature or cryogenic applications. Manufactured from high-quality stainless steel, our insulated pipe shoe clamps combine durability, corrosion resistance, and reliable performance in demanding process environments. Function of SS Insulated Pipe Shoe Clamps • Provide stable pipe support while maintaining insulation continuity • Prevent thermal bridges and reduce energy loss in piping systems • Isolate pipes from supporting structures to minimize heat transfer • Distribute loads evenly, reducing stress on pipelines and insulation • Enhance operational efficiency and protect pipeline coatings Ladhani Metal Corporation manufactures, supplies, and exports SS Insulated Pipe Shoe Clamps in different sizes and designs to meet diverse project requirements across domestic and international markets. Available Grades • SS 304 • SS 304L • SS 316 • SS 316L Applications Commonly used in industries where maintaining insulation and preventing heat loss or gain is critical. • Refineries and petrochemical plants • Cryogenic and LNG facilities • Fertilizer and chemical processing units • Power generation plants and boilers • Marine and offshore engineering projects Uses • Provides insulated support for process pipelines in hot and cold service • Prevents damage to insulation during thermal expansion and movement • Improves efficiency by maintaining process temperature control • Protects against corrosion under insulation (CUI) • Suitable for heavy-duty and high-temperature pipeline systems Features • Integrated insulation design to reduce heat transfer • High load-bearing capacity and durable construction • Resistance to corrosion and oxidation in aggressive environments • Long service life with minimal maintenance requirements • Manufactured in SS 304, 304L, 316, and 316L grades Conclusion The SS Insulated Pipe Shoe Clamp from Ladhani Metal Corporation is a reliable solution for maintaining insulation performance and structural integrity in pipeline systems. Manufactured in SS 304, SS 304L, SS 316, and SS 316L grades, these clamps provide dependable service in industries requiring thermal efficiency, durability, and corrosion resistance. For inquiries or project requirements, contact Ladhani Metal Corporation #Mumbai #Delhi #Bangalore #Hyderabad #Chennai #Kolkata #Pune #Ahmedabad #Surat #Vadodara #Rajkot #Nagpur #Indore #Bhopal #Jaipur #Lucknow #Kanpur #Patna #Ranchi #Jamshedpur #Bhubaneswar #Raipur #Visakhapatnam #Vijayawada #Coimbatore #Madurai #Kochi #Trivandrum #Tiruchirappalli #Mangalore #Mysore #Noida #Gurgaon #Faridabad #Ghaziabad #Ludhiana #Amritsar #Chandigarh #Jalandhar #Agra #Varanasi #Meerut #Aurangabad #Nashik #Solapur #Gwalior #Allahabad #Guwahati #Shillong #PipeShoeClamp #StainlessSteelPipeShoeClamp #SSPipeShoeClamp #PipeShoeClampManufacturer #PipeShoeClampSupplier #PipeShoeClampExporter #PipeShoeClampIndia #IndustrialPipeShoeClamp #HeavyDutyPipeShoeClamp #CustomPipeShoeClamp #HighQualityPipeShoeClamp #304PipeShoeClamp #316PipeShoeClamp #304LPipeShoeClamp #316LPipeShoeClamp #PipeShoeClampFittings #PipeShoeClampSupport #SS304PipeShoeClamp #SS316PipeShoeClamp #SS316LPipeShoeClamp #SS304LPipeShoeClamp #PipeShoeClampDesign #PipeShoeClampApplication #PipeShoeClampForBoilers #PipeShoeClampForRefinery #PipeShoeClampForPetrochemical #PipeShoeClampForPowerPlant #PipeShoeClampForOilAndGas #PipeShoeClampForChemicalPlant #PipeShoeClampSolutions #PipeShoeClampProducts #PipeShoeClampFabrication #PipeShoeClampInstallation #PipeShoeClampSupportSystem #PipeShoeClampAssembly #PipeShoeClampHardware #PipeShoeClampTechnology #DurablePipeShoeClamp #ReliablePipeShoeClamp #PipeShoeClampStockist #PipeShoeClampWholesale #PipeShoeClampTrading #PipeShoeClampDistribution #PipeShoeClampExports #PipeShoeClampWorldwide #PipeShoeClampIndustry #PipeShoeClampMarket #PipeShoeClampOnline #PipeShoeClampComponents #PipeShoeClampSystems

Send Message