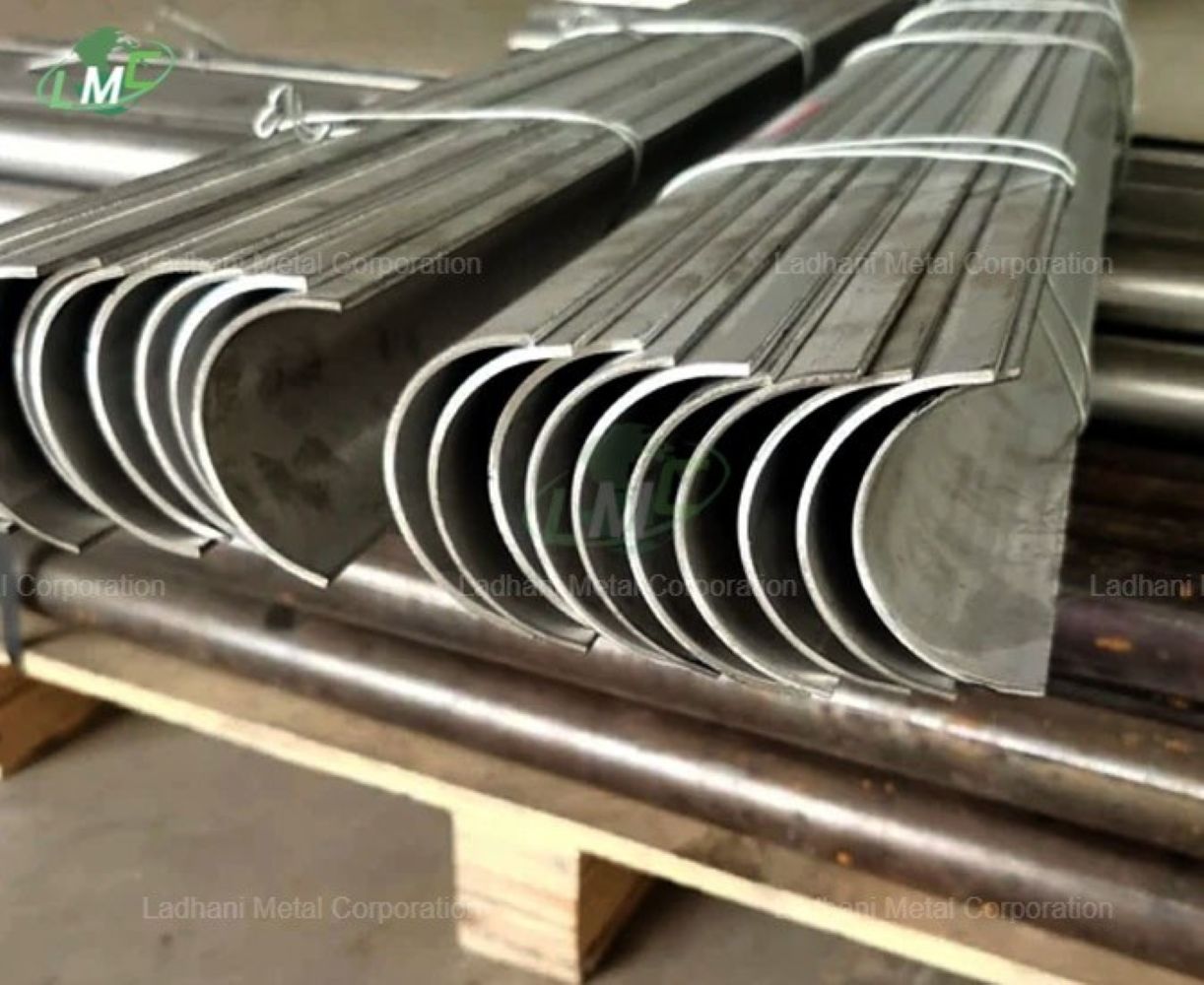

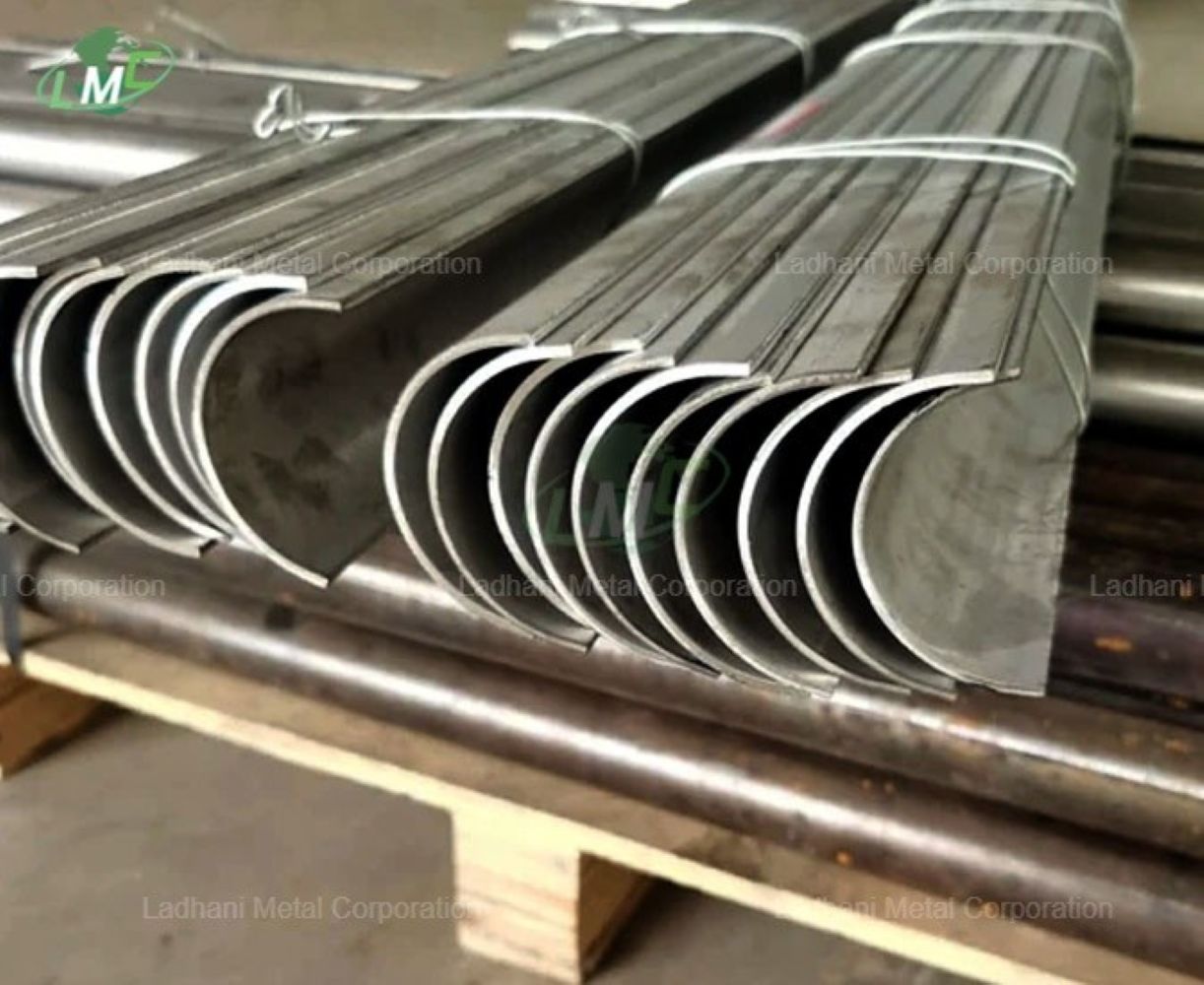

Half Round Tube Shield Ladhani Metal Corporation manufactures precision-engineered Half Round Tube Shields to protect boiler and heat exchanger tubes from corrosion, erosion, and surface degradation. Designed for durability in aggressive environments, these shields are especially suited for thermal equipment where tubes are subjected to high flow velocities, abrasive particles, and flue gas turbulence. Their half-round shape allows easy installation while offering long-term protection and reduced maintenance. 1Cr20Ni14Si2 Half Round Tube Shield for LTSH Tube The 1Cr20Ni14Si2 Half Round Tube Shield is manufactured from a high-temperature-resistant chromium-nickel-silicon alloy. With approximately 20% chromium, 14% nickel, and added silicon, this material offers outstanding oxidation resistance, excellent strength at elevated temperatures, and superior resistance to high-temperature corrosion. It is an ideal choice for shielding Low Temperature Superheater (LTSH) tubes, which are frequently exposed to flue gases carrying ash and particulate matter that can cause rapid wear. The Low Temperature Superheater (LTSH) is a section in a boiler where saturated steam from the steam drum is superheated to a moderately higher temperature before entering the high-temperature superheater stages. Positioned in areas with relatively lower flue gas temperatures, the LTSH helps improve thermal efficiency and reduces moisture content in steam. Due to constant exposure to abrasive flue gases and ash, LTSH tubes are prone to wear and require protective shielding, such as half round tube shields, to extend service life. Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of 1Cr20Ni14Si2 Half Round Tube Shields, providing high-performance shielding solutions for challenging industrial heat transfer applications. Chemical Composition of 1Cr20Ni14Si2 – Heat-Resistant Alloy Steel • Carbon (C): ≤ 0.15% • Manganese (Mn): ≤ 1.50% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Silicon (Si): 1.00 – 2.50% • Chromium (Cr): 19.0 – 22.0% • Nickel (Ni): 13.0 – 15.0% • Iron (Fe): Balance Applications: Best suited for components exposed to oxidizing environments, fluctuating temperatures, and particulate flow where metal surface protection is critical. Uses • Protection of LTSH tubes in thermal power plant boilers • Coverage of heat exchanger tubes in waste heat recovery boilers • Shielding superheater coils from ash erosion and thermal stress • Ideal for utility boilers, steam generators, and flue gas-exposed piping • Applied in industrial boilers within cement, pulp & paper, and refining sectors Features • High-temperature resistance – Performs well in continuous service at elevated temperatures • Oxidation protection – Excellent resistance to flue gas scaling and surface degradation • Precise fitment – Custom curved for exact tube geometry for secure and uniform coverage • Enhanced durability – Reduces erosion, thermal fatigue, and mechanical damage • Versatile installation – Compatible with clamp-on, weld-on, or banding attachment methods • Custom dimensions – Available in multiple sizes and thicknesses per system requirement Applications • thermal power stations – Protects superheater coils and economizer tube bends from low-temperature gas wear • WHRBs – Shields curved tubes in exhaust heat recovery systems • chemical and petrochemical plants – Ensures protection for process steam lines exposed to flue gases • HRSGs – Increases the durability of LTSH coil tubes in combined-cycle systems • boiler and furnace systems – Ideal for superheater areas prone to wear from ash and soot deposition Conclusion The 1Cr20Ni14Si2 Half Round Tube Shield for LTSH Tube by Ladhani Metal Corporation – manufacturer, supplier, and exporter – offers excellent resistance to oxidation, scaling, and thermal damage in low-temperature superheater zones. Its heat-resistant composition and long service life make it a dependable choice for demanding boiler and heat exchanger applications across multiple industries. For custom requirements or technical inquiries, contact Ladhani Metal Corporation.

Send Message