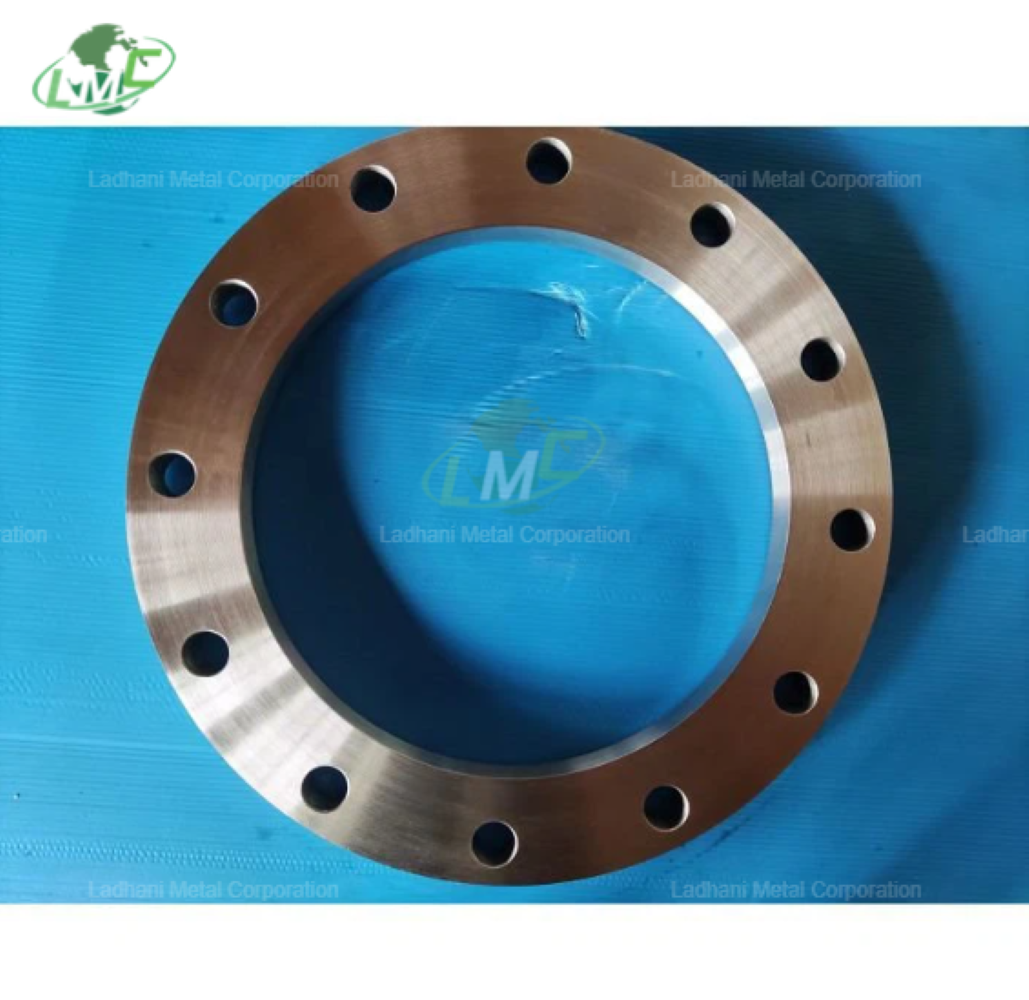

DIN 2633 Inconel flanges PN 16 are precision-engineered weld neck flanges manufactured to the DIN 2633 standard, specifically designed for use in high-temperature and highly corrosive industrial environments. These flanges offer secure, pressure-resistant connections for pipeline systems operating at up to 16 bar (232 psi). Fabricated from premium Inconel alloys such as 600, 625, and 718, they provide excellent resistance to oxidation, thermal stress, and corrosive chemicals, making them ideal for extreme service conditions across various industries. Ladhani Metal Corporation is a trusted global supplier and manufacturer of Inconel flanges, known for its commitment to material integrity, precision engineering, and strict compliance with international quality standards. Each flange is subjected to thorough inspections to meet performance, safety, and durability expectations. Pressure Rating: • PN 16 (16 bar / 232 psi): Suitable for high-performance pipeline systems requiring resistance to thermal cycling, corrosion, and pressure fluctuation. Flange Type: • Weld Neck Flanges Long tapered hub design ensures smooth fluid transitions and reduces mechanical stress at the base, offering strong and vibration-resistant joints. • Flat Face (FF) Flanges Promotes even gasket loading and is compatible with soft or cast-mating components, enhancing sealing efficiency and system longevity. Inconel Grades and Full Composition: Inconel 600 • Nickel (Ni): ≥ 72.0% • Chromium (Cr): 14.0 – 17.0% • Iron (Fe): 6.0 – 10.0% • Carbon (C): ≤ 0.15% • Manganese (Mn): ≤ 1.0% • Silicon (Si): ≤ 0.5% • Sulfur (S): ≤ 0.015% Applications: Ideal for high-temperature furnace components, chemical processing, and food equipment exposed to acidic and alkaline environments. Inconel 625 • Nickel (Ni): 58.0% min • Chromium (Cr): 20.0 – 23.0% • Molybdenum (Mo): 8.0 – 10.0% • Niobium (Nb) + Tantalum (Ta): 3.15 – 4.15% • Iron (Fe): ≤ 5.0% • Carbon (C): ≤ 0.10% • Manganese (Mn): ≤ 0.5% • Silicon (Si): ≤ 0.5% Applications: Suitable for seawater systems, offshore oil and gas equipment, aerospace ducting, and high-strength chemical processing. Inconel 718 • Nickel (Ni): 50.0 – 55.0% • Chromium (Cr): 17.0 – 21.0% • Iron (Fe): Balance • Niobium (Nb) + Tantalum (Ta): 4.75 – 5.5% • Molybdenum (Mo): 2.8 – 3.3% • Titanium (Ti): 0.65 – 1.15% • Aluminum (Al): 0.2 – 0.8% • Carbon (C): ≤ 0.08% Applications: Extensively used in aerospace engines, turbine components, cryogenic storage tanks, and high-strength fasteners due to excellent fatigue, creep, and rupture resistance. Applications of DIN 2633 Inconel Flanges PN 16: • Petrochemical and Refining Industries Withstands exposure to high-temperature hydrocarbons, acids, and corrosive gases. • Marine and Offshore Installations Corrosion-resistant in saltwater and high-pressure environments, ideal for subsea and topside systems. • Aerospace and Power Generation Used in turbine and exhaust systems where strength retention at elevated temperatures is critical. • Chemical Processing Plants Stable under acidic, oxidizing, and reducing agents in continuous and batch processing systems. • Heat Exchangers and Reactors Reliable performance in thermal cycling and aggressive fluid handling applications. Key Features: • Designed in accordance with DIN 2633 specifications • Rated PN 16 for secure medium-pressure operation • Weld neck design improves alignment and minimizes mechanical stress • Available in Inconel grades 600, 625, and 718 • Exceptional resistance to high-temperature oxidation and corrosion • High tensile strength and fatigue resistance under mechanical loads • Tailored dimensions, surface finishes, and specifications available upon request Conclusion: DIN 2633 Inconel Flanges PN 16 from Ladhani Metal Corporation are engineered to meet the toughest demands of modern industry. Offering excellent resistance to high-temperature and corrosive environments, these flanges made from Inconel 600, 625, and 718 are ideal for critical applications across aerospace, petrochemical, marine, and power generation sectors. For detailed product options, technical support, or a customized quote, contact Ladhani Metal Corporation today.