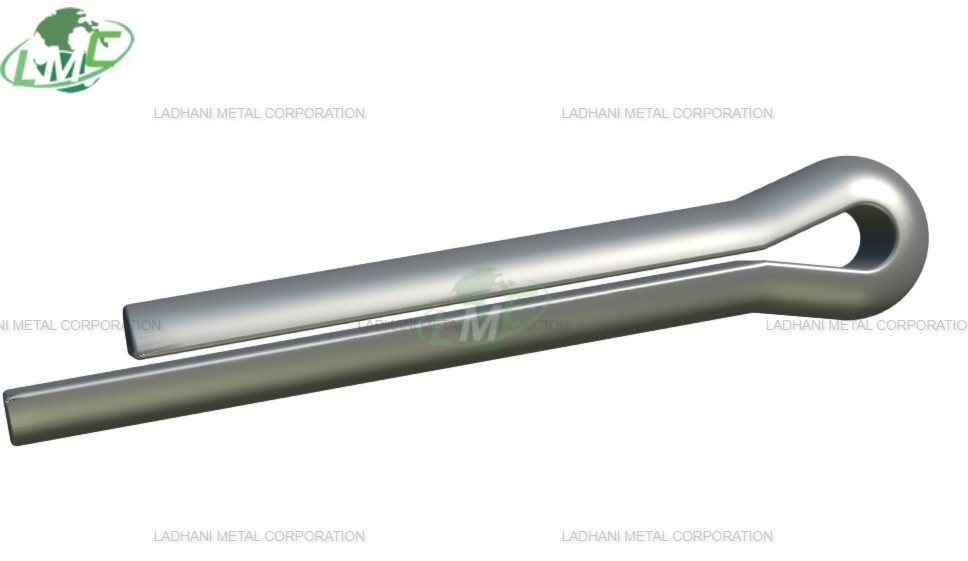

Ladhani Metal Corporation offers SS 316 Boiler Half Round Tube Shields designed to protect straight boiler and heat exchanger tubes from corrosion, erosion, and high-temperature damage in aggressive service environments. Manufactured from austenitic stainless steel grade SS 316, these shields provide superior corrosion resistance, especially against chlorides and acidic flue gases. SS 316 is ideal for applications where moisture, chemical vapors, and thermal stress are present, including marine boilers, waste heat recovery systems, and chemical processing units. Each shield is precision-formed into a half-round profile for a close and secure fit over the outer surface of boiler tubes. This design provides a robust barrier against soot blower impact, abrasive ash particles, and corrosive condensates. The mechanical protection offered by SS 316 shields significantly extends tube service life and reduces maintenance downtime. Ladhani Metal Corporation manufactures, supplies, and exports SS 316 Boiler Half Round Tube Shields in multiple diameters, lengths, and thicknesses to meet the exact specifications of domestic and international projects. SS 316 Grade Chemical Composition – Austenitic Stainless Steel • Carbon (C): ≤ 0.08% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 16.0 – 18.0% • Nickel (Ni): 10.0 – 14.0% • Molybdenum (Mo): 2.0 – 3.0% • Iron (Fe): Balance Applications: Suitable for corrosive and high-moisture environments such as power plants, waste heat boilers, refineries, and process heaters. Uses • Protection of straight boiler tubes in moist or acidic gas streams • Used in marine boilers and off-shore heating systems • Shields against corrosion, scaling, and thermal erosion • Installed in chemical and petrochemical flue gas lines • Suitable for food, pharmaceutical, and pulp industry boilers Features • Excellent corrosion resistance – Especially effective against chlorides and chemicals • High thermal stability – Performs under prolonged heat and steam exposure • Durable and long-lasting – Reduces tube wear and replacement frequency • Precision fit – Half-round shape conforms to tube curvature for full coverage • Easy to install – Can be clamped, banded, or tack welded as needed • Export quality – Manufactured to meet global boiler protection standards Applications • Power generation and utility boilers – For flue gas and steam tube protection • Chemical and fertilizer industries – Withstands corrosive vapors and condensates • Pulp and paper mills – Used in high-moisture heating environments • Waste heat recovery systems – Effective in corrosive flue gas streams Conclusion The SS 316 Boiler Half Round Tube Shield from Ladhani Metal Corporation offers robust, corrosion-resistant protection for boiler tubes exposed to chemically aggressive and high-moisture conditions. With added molybdenum content for enhanced durability and precise half-round design, these shields are ideal for a wide range of industrial and marine boiler applications. For customized specifications, export orders, or technical assistance, contact Ladhani Metal Corporation. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Salem #Erode #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Hassan #Cuttack #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Gaya #Muzaffarpur #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #halftubeshield #utypehalftubeshield

Send Message