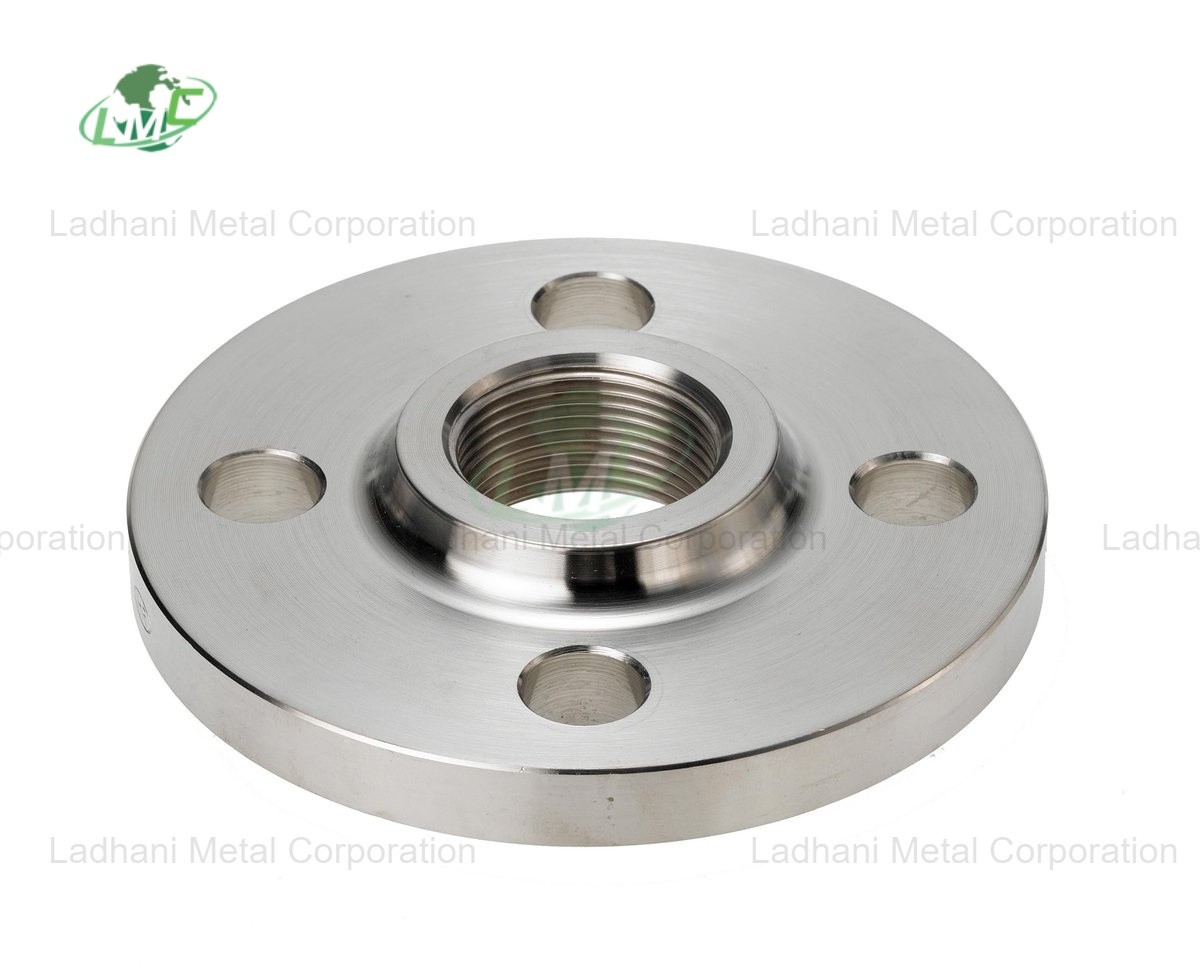

Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of high-quality Hastelloy C-4 Butterfly Valves. A Hastelloy C-4 butterfly valve is a corrosion-resistant and high-performance flow control device designed to regulate, isolate, or throttle the flow of liquids, gases, and aggressive chemicals in demanding industrial environments. Manufactured using Hastelloy C-4 alloy, this valve offers exceptional stability at high temperatures and excellent resistance to strong oxidizing agents, acids, and chloride-induced corrosion. It is widely used in chemical processing, pollution control, and other applications that involve extreme temperatures and highly corrosive conditions. Functions The key functions of a Hastelloy C-4 butterfly valve include: • Controlling and isolating the flow of corrosive fluids and gases. • Providing bubble-tight shut-off with minimal torque operation. • Allowing accurate throttling for precise process control. • Maintaining efficiency by reducing pressure loss in the flow system. • Offering high resistance to oxidation and stress-corrosion cracking. • Ensuring consistent mechanical properties under high temperatures. Material Characteristics and Composition of Hastelloy C-4 Hastelloy C-4 (UNS N06455) is a nickel-chromium-molybdenum alloy developed for exceptional thermal stability and corrosion resistance in strong oxidizing environments. It maintains its ductility and toughness even after prolonged exposure to high temperatures. Typical Composition of Hastelloy C-4: • Nickel (Ni) – Balance • Chromium (Cr) – 14.0–18.0% • Molybdenum (Mo) – 14.0–17.0% • Iron (Fe) – 3.0% max • Cobalt (Co) – 2.0% max • Manganese (Mn) – 1.0% max • Silicon (Si) – 0.8% max • Vanadium (V) – 0.35% max • Tungsten (W) – 0.02% max • Carbon (C) – 0.015% max • Phosphorus (P) – 0.04% max • Sulfur (S) – 0.03% max Types of Hastelloy C-4 Butterfly Valves • Flanged Hastelloy C-4 Butterfly Valve – Equipped with strong flanged ends available in Class 150, Class 300, and Class 600 for secure and leak-proof service under high-pressure and corrosive conditions. • Threaded Hastelloy C-4 Butterfly Valve – Compact design with threaded ends for small and medium pipelines, providing easy installation and reliable operation. Applications / Uses Hastelloy C-4 butterfly valves are widely used in industries that demand superior resistance to chemical attack and high-temperature performance: • Chemical and petrochemical processing plants. • Power generation and energy facilities. • Desalination and water treatment systems. • Pharmaceutical and biotechnology industries. • Acid production and fertilizer plants. • Marine and offshore installations. • Pollution control and waste management systems. • Pulp and paper manufacturing. Conclusion Hastelloy C-4 butterfly valves provide outstanding corrosion resistance, excellent thermal stability, and mechanical strength in the most demanding industrial environments. They are ideal for handling oxidizing chemicals, acids, and other aggressive fluids where conventional materials fail. Available in flanged and threaded configurations, these valves ensure efficient, leak-proof, and long-lasting service. For any requirement or orders, contact Ladhani Metal Corporation (LMC), a trusted manufacturer, supplier, and exporter of premium Hastelloy C-4 Butterfly Valves.