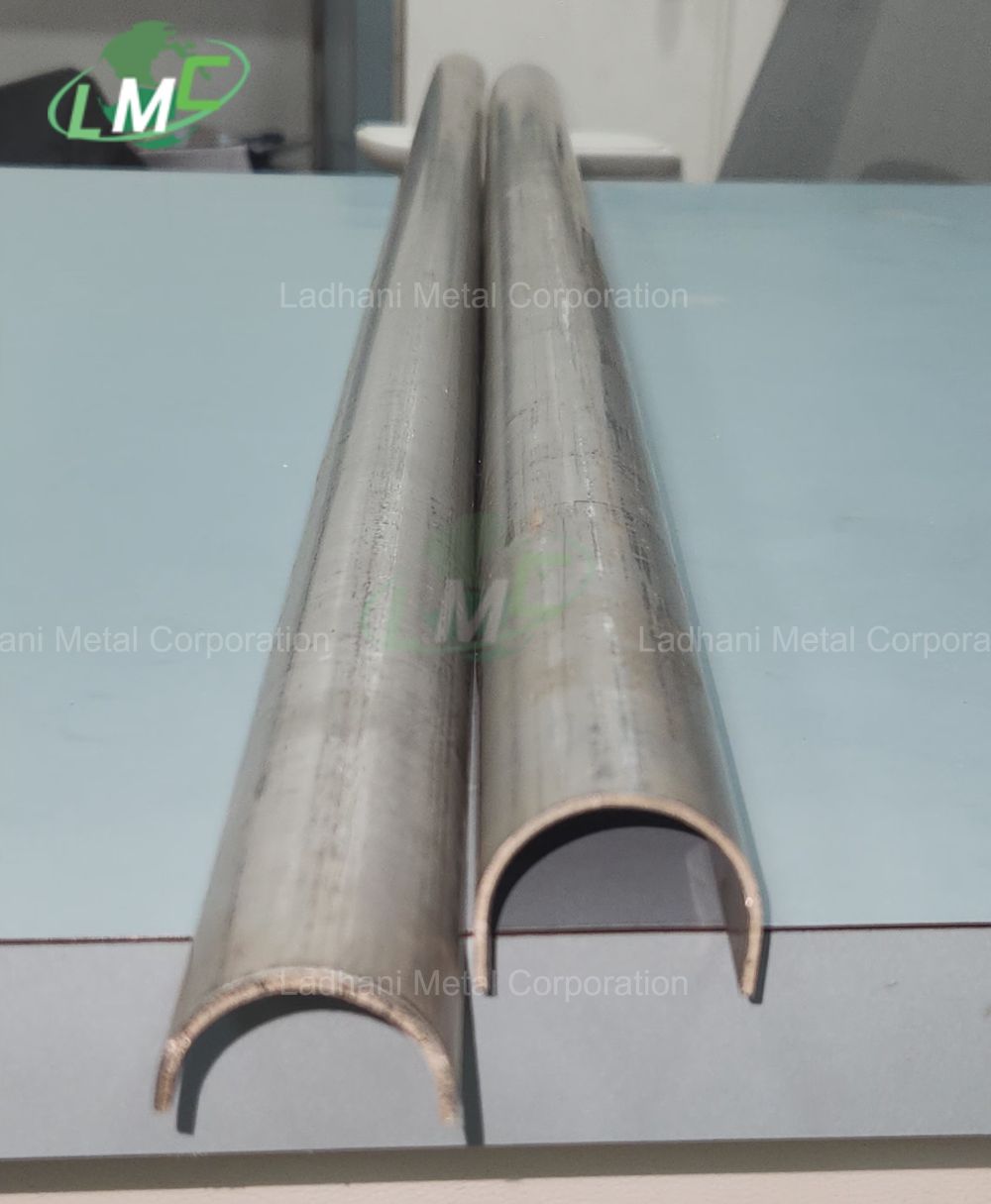

Ladhani Metal Corporation manufactures and exports Outer Tube Shields for U-Bends, designed to protect the most vulnerable boiler tube sections where erosion, oxidation, and soot blower impacts are most severe. U-Bend tubes in boilers are subjected to direct flue gas strikes and abrasive ash flows, making them highly prone to localized thinning and early failure. Outer Tube Shields are precision-formed to cover the external arc of U-Bends, acting as sacrificial wear barriers that extend the operational life of tubes and improve the reliability of boiler performance. Function of U-Bend Tube Shields • Protect U-Bend tubes from erosive flue gas, abrasive ash particles, and soot blower jet damage • Provide resistance against high-temperature oxidation and scaling • Extend the service life of tubes in superheaters, reheaters, economizers, and heat recovery units • Reduce tube maintenance frequency and operational downtime Ladhani Metal Corporation manufactures, supplies, and exports Outer Tube Shields for U-Bend tubes in various lengths, diameters, thicknesses, and bend radii to suit both domestic and international boiler applications. Available Grades • SS 304 / SS 304L • SS 310 / SS 310S • SS 316 / SS 316L • SS 410 / SS 420 / SS 430 • 1Cr13 • 1Cr18Ni9Ti • 1Cr20Ni14Si2 • 1Cr25Ni20Si2 • Cr23Ni13 • Cr25Ni20 Applications: Ideal for superheater, reheater, and economizer U-Bends in power plants, industrial boilers, WHRBs (Waste Heat Recovery Boilers), and HRSGs (Heat Recovery Steam Generators). Uses • Shields U-Bend tubes in high-velocity gas and abrasive ash zones • Provides erosion protection in soot blower impact areas • Extends tube life in critical bent tube regions of boilers • Widely applied in utility boilers, industrial boilers, and petrochemical heating systems Features • High resistance to erosion, oxidation, and scaling • Strong thermal stability in elevated temperature service conditions • Precision-engineered fit for external arc coverage of U-Bends • Manufactured in stainless steel and special alloy grades for diverse applications Applications • Power generation boilers – Protection for U-Bend tubes in superheater and reheater sections • Waste heat recovery boilers – Guards U-Bends against abrasive flue gases • Heat recovery steam generators – Reliable in cyclic thermal environments • Industrial boilers – Provides durable shielding in flue gas paths Conclusion The Outer Tube Shield for U-Bend from Ladhani Metal Corporation provides reliable and durable protection for critical boiler tube bends exposed to erosion, oxidation, and abrasive flue gas wear. Manufactured in stainless steel grades SS 304/304L, SS 310/310S, SS 316/316L, SS 410/420/430, and special alloys such as 1Cr13, 1Cr18Ni9Ti, 1Cr20Ni14Si2, 1Cr25Ni20Si2, Cr23Ni13, and Cr25Ni20, these shields are designed for long service life, minimal maintenance, and export-ready quality for power and industrial applications worldwide. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Muzaffarpur#halftubeshield #utypehalftubeshield #tubeshieldexporter #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #HalfRoundReheaterShield #ReheaterTubeShield #BoilerReheaterProtection #PowerPlantTubeShield #BoilerErosionShield #SteamBoilerTubeShield #HighTempTubeShield #BoilerWearProtection