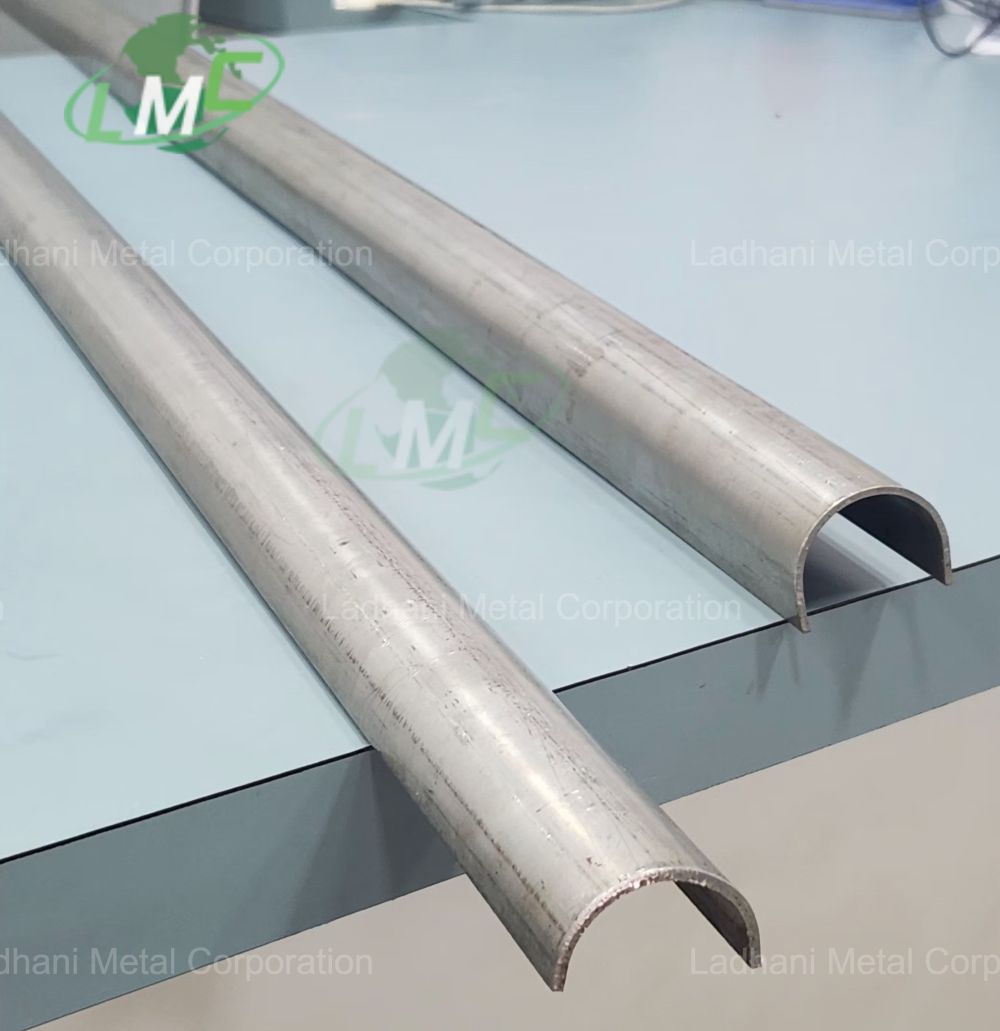

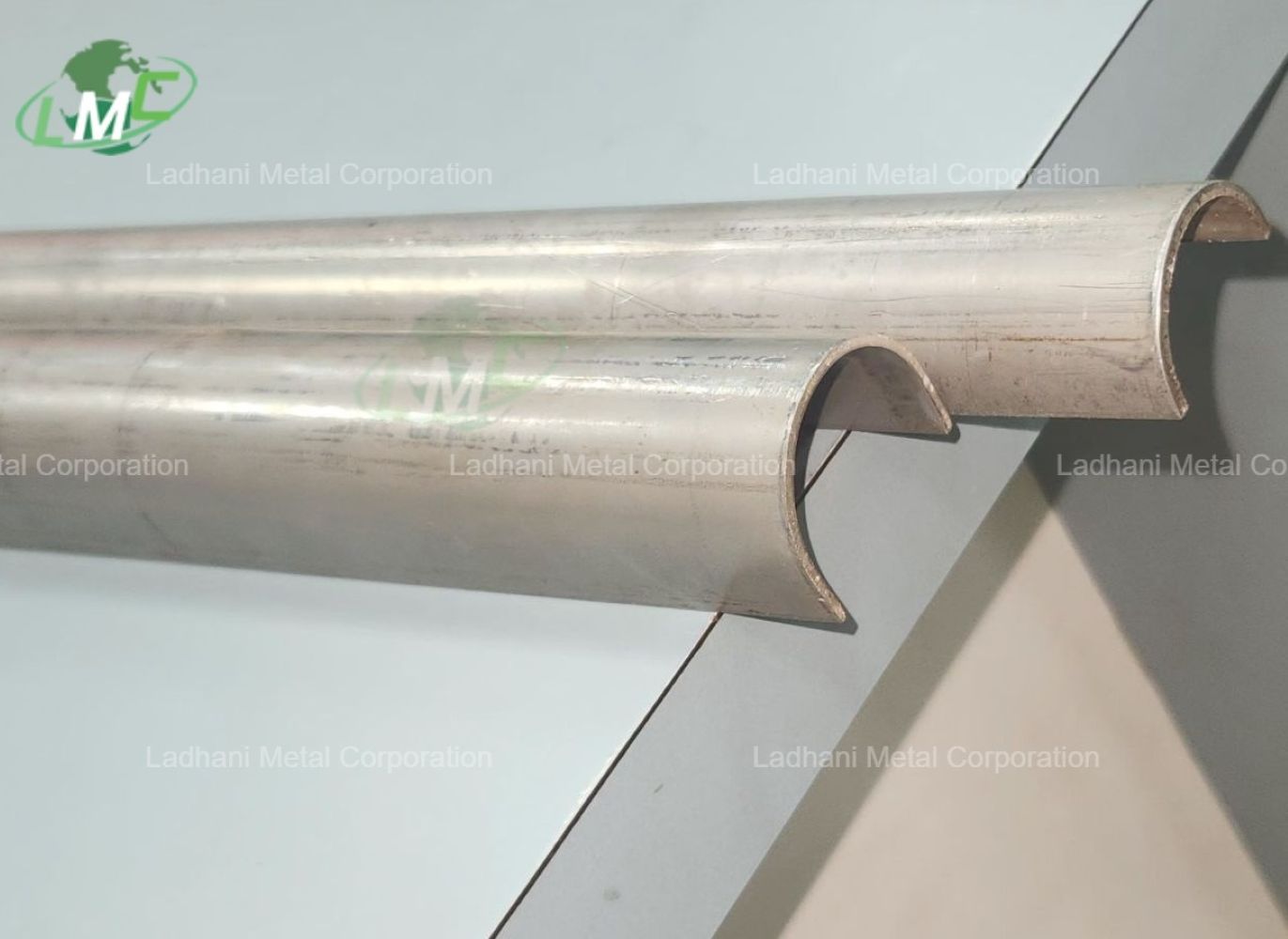

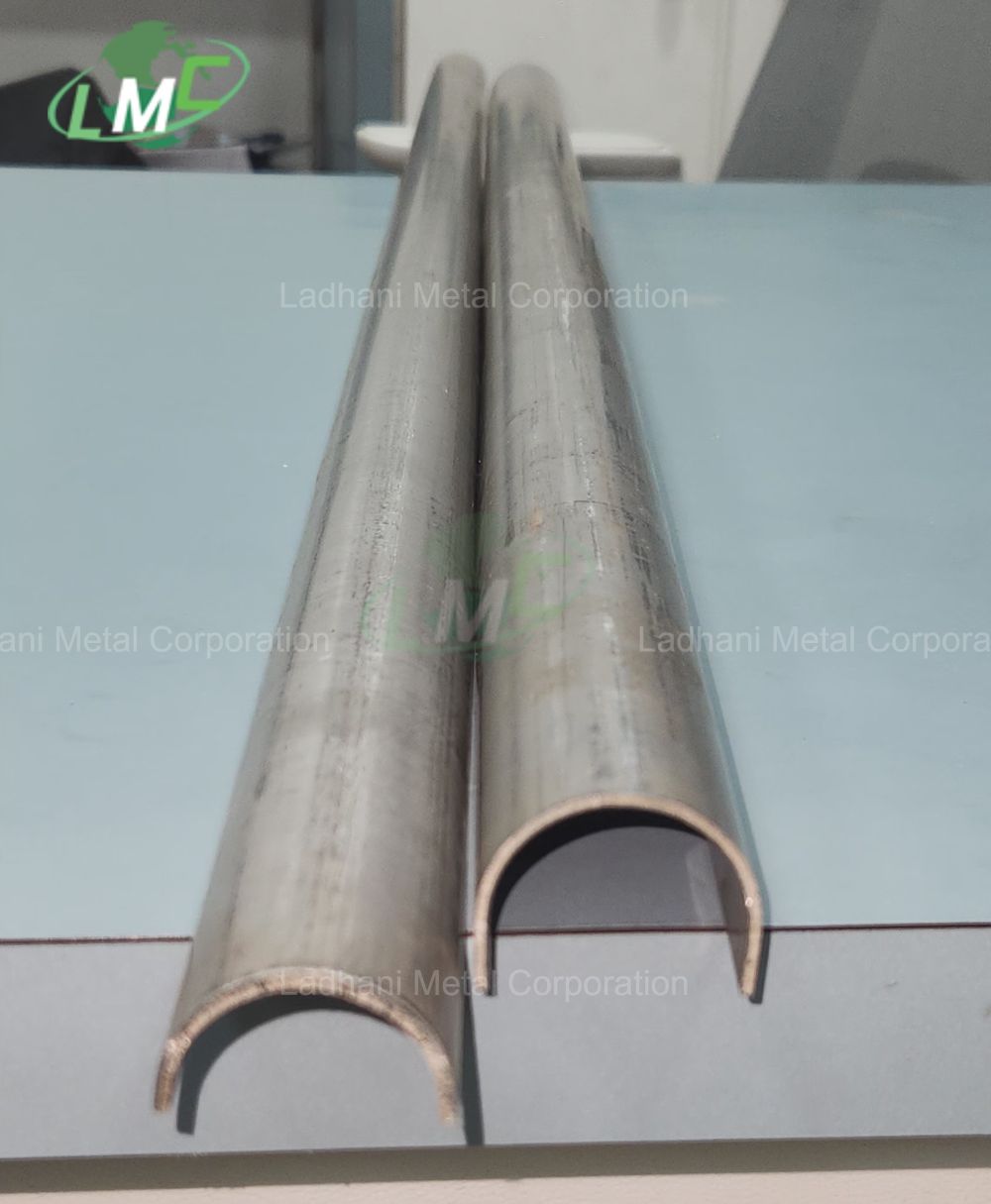

Ladhani Metal Corporation offers Clip-On Tube Shields designed for quick installation and reliable protection of boiler tubes in power plants, refineries, petrochemical heaters, waste heat recovery boilers (WHRBs), and heat recovery steam generators (HRSGs). These shields feature a clip-on fastening mechanism that allows them to be mounted securely onto tube surfaces without welding, reducing installation time, labor, and downtime while still ensuring effective tube protection in high-wear areas. Function of Clip-On Tube Shields • Provide erosion and corrosion protection for boiler tubes in flue gas paths • Reduce downtime with fast, non-weld installation and removal • Shield tubes from soot blower jets, ash particle erosion, and hot flue gases • Extend service life of boiler components under high-temperature operation Ladhani Metal Corporation manufactures, supplies, and exports Clip-On Tube Shields in various sizes, thicknesses, and radii, catering to both domestic and international market requirements. Available Grades • SS 304 / SS 304L • SS 310 / SS 310S • SS 316 / SS 316L • SS 410 / SS 420 / SS 430 • 1Cr13 • 1Cr18Ni9Ti • 1Cr20Ni14Si2 • 1Cr25Ni20Si2 • Cr23Ni13 • Cr25Ni20 Applications: Widely used in reheater, superheater, economizer, and LTSH sections where high-velocity flue gases and abrasive particles cause localized tube erosion. Uses • Protects boiler tubes from erosion, oxidation, and mechanical wear • Shields against soot blower jet impingement • Reduces costly maintenance and tube replacement • Suitable for power plants, HRSGs, WHRBs, and refinery heaters Features • Clip-on design – Easy installation and removal without welding • Strong hold for reliable protection in high-velocity zones • Corrosion and oxidation resistance at elevated temperatures • Designed for accurate fit and long-term service Applications • Power generation boilers – Fast protection solution for reheater/superheater tubes • Waste heat recovery boilers – Guards tubes in erosive gas flows • HRSGs – Provides durable shielding with minimal downtime • Industrial and petrochemical steam systems – Reliable in high-temperature cycles Conclusion The Clip-On Tube Shield from Ladhani Metal Corporation offers a practical and efficient solution for protecting boiler tubes from erosion and corrosion without requiring welding. Available in a wide range of stainless steel and alloy grades, these shields deliver precision, durability, and global supply capability to meet the needs of power generation and process industries.

Send Message