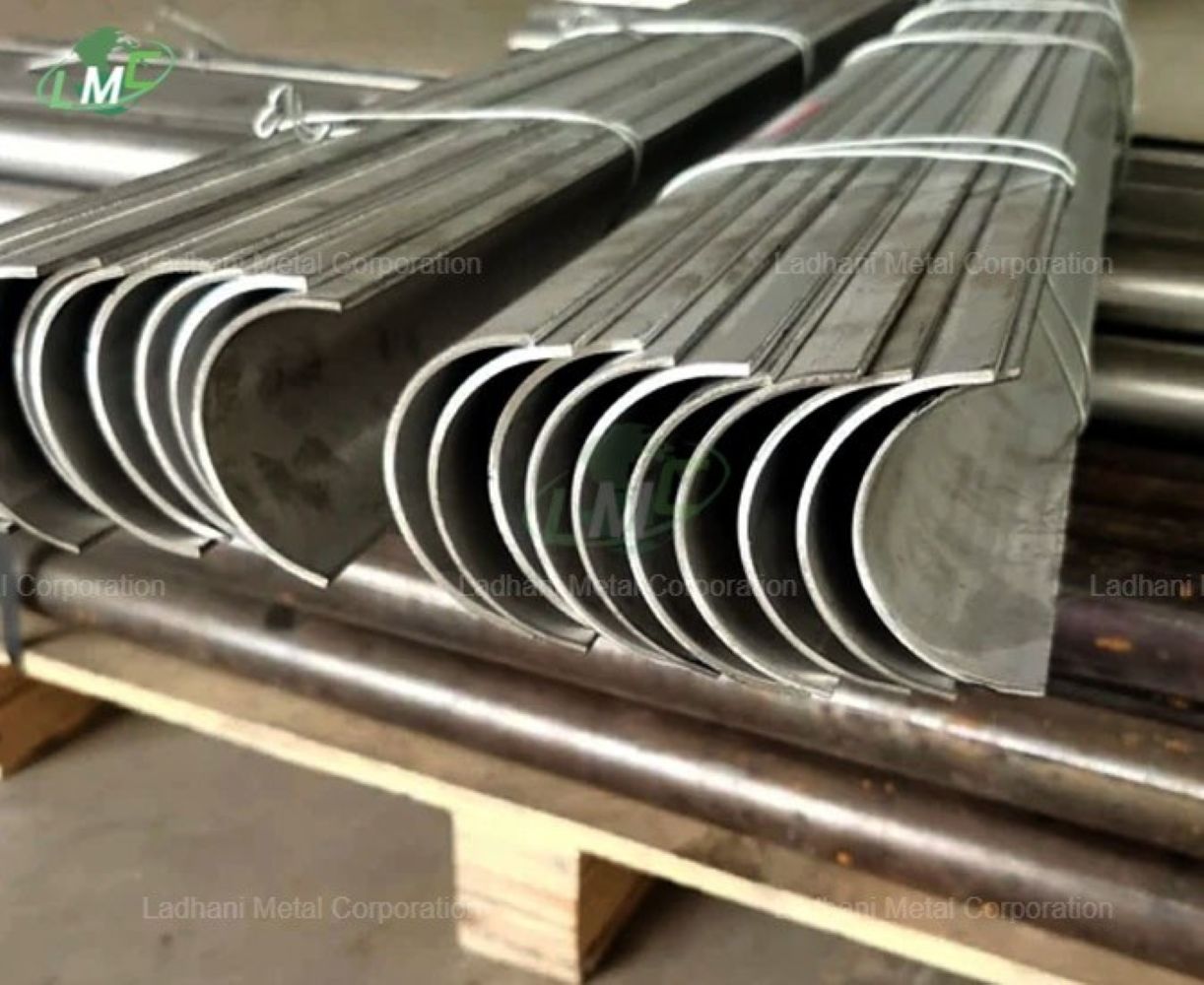

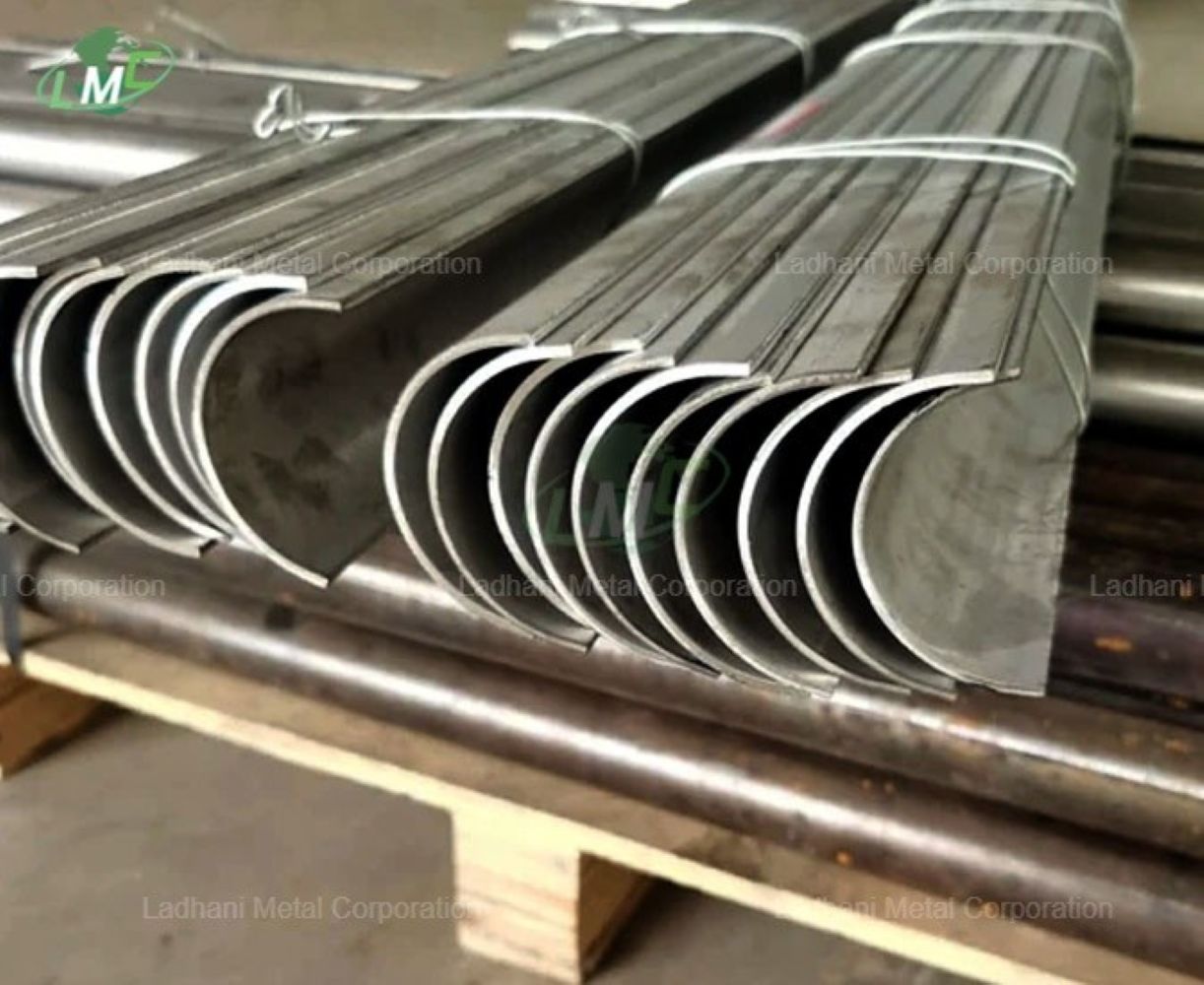

Half Round Tube Shield Ladhani Metal Corporation manufactures 1Cr25Ni20Si2 Half Round Straight Tube Shields to deliver exceptional protection to straight boiler and heat exchanger tubes in aggressive high-temperature environments. 1Cr25Ni20Si2 Half Round Straight Tube Shield The 1Cr25Ni20Si2 Half Round Straight Tube Shield is fabricated in a semi-cylindrical form to protect the outer surface of straight tubes from scaling, tube wall thinning, and structural damage caused by hot combustion gases or ash-laden flows. Its high silicon content improves oxidation resistance and inhibits the formation of brittle scales, while the alloy’s high-temperature stability ensures long service life under cyclic heating and cooling operations. Ladhani Metal Corporation is a trusted manufacturer, supplier, and exporter of 1Cr25Ni20Si2 Half Round Straight Tube Shields, offering precise fit and durable tube protection across thermal and petrochemical industries. Material Grade 1Cr25Ni20Si2 – High-chromium, high-nickel heat-resistant alloy with enhanced silicon for improved oxidation and thermal shock resistance. Chemical Composition of 1Cr25Ni20Si2 • Carbon (C): ≤ 0.10% • Silicon (Si): 1.50 – 2.50% • Manganese (Mn): ≤ 1.50% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Chromium (Cr): 24.0 – 26.0% • Nickel (Ni): 19.0 – 22.0% • Iron (Fe): Balance Uses • Radiant section protection in waste heat boilers and reformers • Straight tube shielding in high-temperature furnaces • Heat recovery units in ammonia, hydrogen, and methanol plants • Erosion control in fluidized bed combustion systems Features • Excellent oxidation and scaling resistance at high temperatures • High thermal stability under long-term service • Superior resistance to carburization and sulfidation • Durable against erosion from high-velocity gas and ash • Maintains mechanical integrity under thermal shock • Custom-fabricated to match tube size, radius, and operational needs Applications • petrochemical and fertilizer plants – For reformer and convection section protection • power generation – In boilers, WHRBs, and waste incinerators • thermal process systems – For furnace and heat exchanger tube shielding • hydrogen and ammonia production – Suitable for synthesis gas environments • metallurgy – For steel reheating furnaces and heat treatment zones Conclusion 1Cr25Ni20Si2 Half Round Straight Tube Shields from Ladhani Metal Corporation are engineered for performance in the harshest high-temperature environments. Their robust composition and resistance to thermal and chemical degradation make them essential for extending the life of straight tubes exposed to extreme flue gas conditions. For orders, custom fabrication, and technical support, contact Ladhani Metal Corporation. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Salem #Erode #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Hassan #Cuttack #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Gaya #Muzaffarpur #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #halftubeshield #utypehalftubeshield #tubeshieldexporter