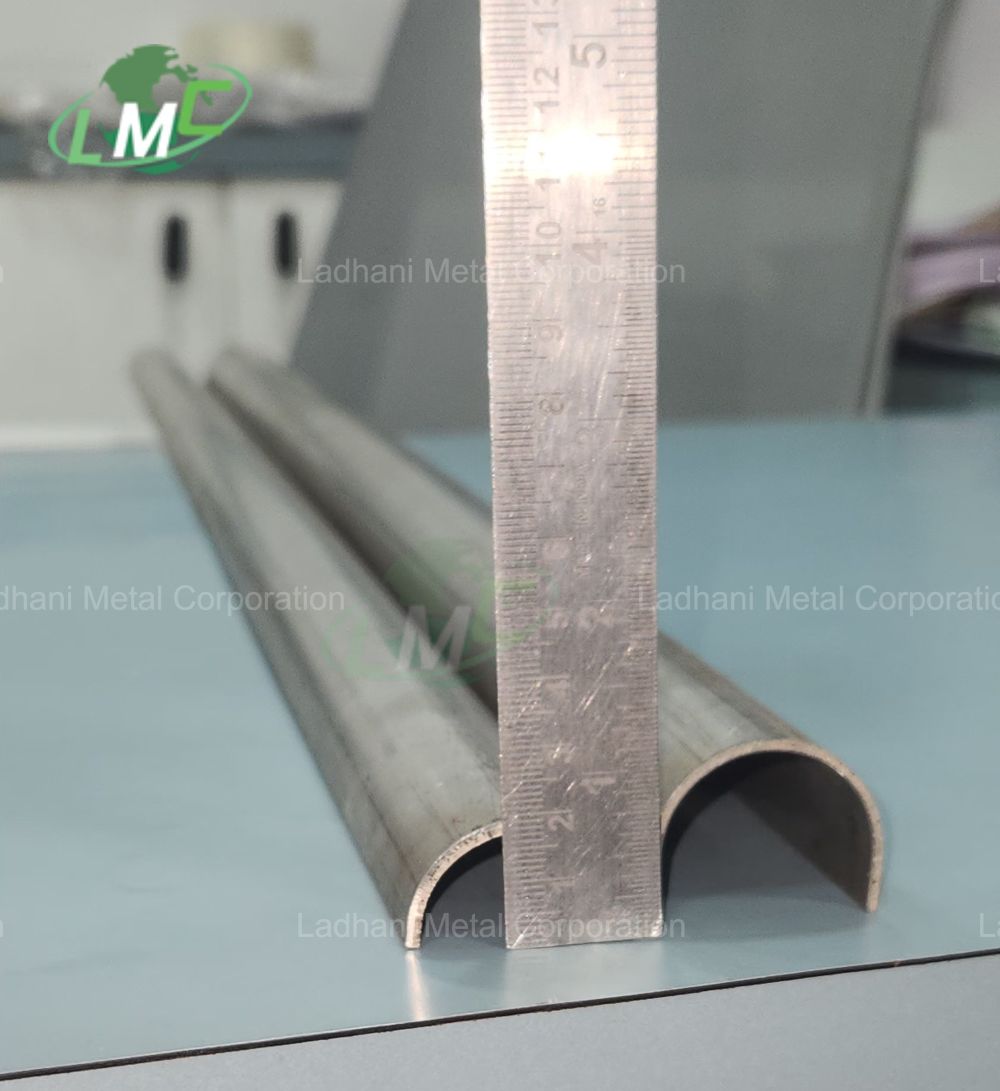

Ladhani Metal Corporation manufactures and supplies SS Heat-Resistant Alloy Tube Shields designed to protect boiler tubes, reheaters, superheaters, economizers, and HRSG units exposed to high-temperature and erosive environments. These shields are engineered from stainless steels and special heat-resistant alloys that ensure excellent resistance to oxidation, scaling, and particle erosion. Their half-round and bend-formed designs provide a secure fit around straight tubes, elbows, and U-bends, extending operational life and reducing tube maintenance frequency. Function of SS Heat-Resistant Alloy Tube Shields • Protect tubes from erosion, oxidation, and soot blower impact • Withstand temperatures exceeding 600°C under boiler operating conditions • Prevent premature thinning, cracking, and tube leakage • Extend service life of steam-generating equipment in power and process industries Ladhani Metal Corporation manufactures, supplies, and exports SS Heat-Resistant Alloy Tube Shields in various thicknesses, lengths, and bend radii to meet domestic and international boiler standards. Available Grades • SS 304 / SS 304L • SS 310 / SS 310S • SS 316 / SS 316L • SS 410 / SS 420 / SS 430 • 1Cr13 • 1Cr18Ni9Ti • 1Cr20Ni14Si2 • 1Cr25Ni20Si2 • Cr23Ni13 • Cr25Ni20 Applications: Power plants, waste heat recovery boilers (WHRBs), heat recovery steam generators (HRSGs), petrochemical heaters, cement plants, and industrial furnaces requiring long-term resistance to high-temperature erosion and flue gas corrosion. Uses • Shields reheater, superheater, and economizer tubes • Provides erosion protection for U-bends and elbow bends • Guards tubes against soot blower and high-velocity flue gas damage • Ensures longer service life of boiler and process equipment Features • High-temperature strength and creep resistance • Excellent resistance to scaling and oxidation • Precision fit for multiple tube geometries • Available in stainless steel and heat-resistant alloy grades Applications • Thermal power stations – Reliable tube protection in high-temperature zones • WHRBs and HRSGs – Durability under erosive and cyclic operating conditions • Petrochemical and industrial heaters – Performance under aggressive heat cycles • Process industries – Reduced tube wear and maintenance costs Conclusion The SS Heat-Resistant Alloy Tube Shields by Ladhani Metal Corporation deliver robust, export-ready solutions for protecting boiler tubes against high-temperature erosion, oxidation, and soot blower damage. Offered in stainless steels (304, 304L, 310, 310S, 316, 316L, 410, 420, 430) and heat-resistant alloys (1Cr13, 1Cr18Ni9Ti, 1Cr20Ni14Si2, 1Cr25Ni20Si2, Cr23Ni13, Cr25Ni20), these shields provide precision fit, superior durability, and long service life in demanding boiler environments. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Muzaffarpur#halftubeshield #utypehalftubeshield #tubeshieldexporter #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #HalfRoundReheaterShield #ReheaterTubeShield #BoilerReheaterProtection #PowerPlantTubeShield #BoilerErosionShield #SteamBoilerTubeShield #HighTempTubeShield #BoilerWearProtection

Send Message