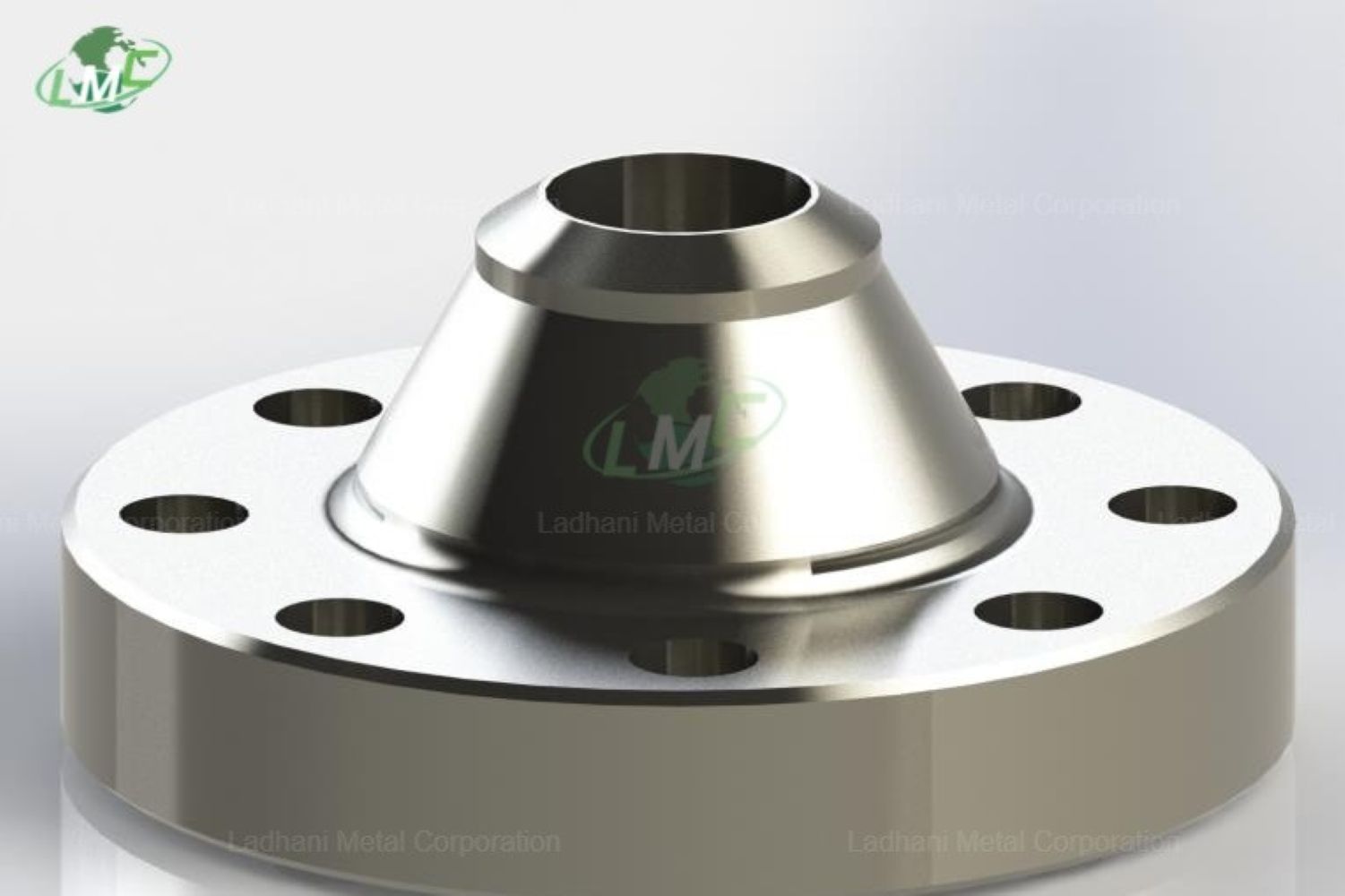

Inconel flanges

DIN 2632 Inconel flanges PN 10 are precision-engineered weld neck flanges manufactured in accordance with the DIN 2632 standard. Designed for medium-pressure applications up to 10 bar (145 psi), these flanges offer exceptional resistance to high temperatures, oxidation, and aggressive chemical environments. Produced using high-performance Inconel alloys, they ensure reliable operation in highly corrosive and thermally demanding industrial systems.

Ladhani Metal Corporation is a globally recognized manufacturer and supplier of Inconel flanges, known for engineering excellence and stringent quality control. Each flange undergoes rigorous testing to meet relevant industrial specifications and environmental safety standards.

Pressure Rating:

• PN 10 (10 bar / 145 psi): Suitable for medium-pressure pipeline systems requiring superior corrosion and temperature resistance.

Flange Type:

• Weld Neck Flanges

Engineered with a long tapered hub to ensure accurate pipe alignment and minimize stress concentration at the flange base. This design allows smoother fluid flow and reinforces joint strength.

• Flat Face (FF) Flanges

Flat face configuration ensures even gasket compression, especially suited for systems using soft gaskets or mating with cast components.

Inconel Grades and Composition:

Inconel 600

• Nickel (Ni): 72.0% minimum

• Chromium (Cr): 14.0–17.0%

• Iron (Fe): 6.0–10.0%

• Carbon (C): ≤ 0.15%

• Manganese (Mn): ≤ 1.0%

• Silicon (Si): ≤ 0.5%

Applications: Inconel 600 offers excellent resistance to high-temperature oxidation and corrosion. Commonly used in chemical processing, food industry heat exchangers, and marine exhaust systems.

Inconel 625

• Nickel (Ni): Balance

• Chromium (Cr): 20.0–23.0%

• Molybdenum (Mo): 8.0–10.0%

• Niobium (Nb): 3.15–4.15%

• Iron (Fe): ≤ 5.0%

• Carbon (C): ≤ 0.10%

• Manganese (Mn): ≤ 0.50%

• Silicon (Si): ≤ 0.50%

Applications: Inconel 625 is known for its outstanding fatigue strength and resistance to pitting, crevice corrosion, and stress corrosion cracking. It is widely used in marine, chemical, aerospace, and nuclear sectors.

Inconel 718

• Nickel (Ni): 50–55%

• Chromium (Cr): 17–21%

• Iron (Fe): Balance

• Niobium (Nb): 4.75–5.5%

• Molybdenum (Mo): 2.8–3.3%

• Titanium (Ti): 0.65–1.15%

• Aluminum (Al): 0.2–0.8%

• Cobalt (Co): ≤ 1.0%

• Carbon (C): ≤ 0.08%

Applications: Inconel 718 offers exceptional tensile, fatigue, and creep resistance at temperatures up to 700°C. It is extensively used in aerospace engines, gas turbines, nuclear reactors, and high-performance industrial equipment where superior mechanical strength and corrosion resistance are required.

Applications of DIN 2632 Inconel Flanges PN 10:

• Chemical and Petrochemical Industry

Ideal for systems carrying corrosive chemicals, acids, and oxidizing agents at elevated temperatures.

• Marine and Offshore

Used in saltwater piping, offshore platforms, and naval systems requiring materials with high corrosion and heat resistance.

• Power Generation

Suitable for high-temperature applications in power plants, heat exchangers, and turbine systems.

• Aerospace and Defense

Applied in jet engine components, space propulsion systems, and structural parts subjected to extreme pressure and heat.

Key Features:

• Manufactured to DIN 2632 specifications

• PN 10 pressure rating for medium-pressure systems

• Weld neck design for superior mechanical integrity

• Available in Inconel 600, 625, and 718 for application-specific performance

• Flat face option for improved gasket compression

• Excellent resistance to oxidation, corrosion, and high-temperature stress

• Suitable for critical applications in chemical, marine, aerospace, and energy sectors

• Custom sizes, finishes, and alloys available upon request

Conclusion:

DIN 2632 Inconel Flanges PN 10 from Ladhani Metal Corporation deliver unmatched reliability and durability in medium-pressure environments where heat and corrosion are persistent challenges. With a selection of Inconel grades including 600, 625, and 718, these flanges are ideal for use in chemical processing, marine engineering, power generation, and aerospace industries. For customized solutions, technical guidance, or pricing, contact Ladhani Metal Corporation today.

Send

Message