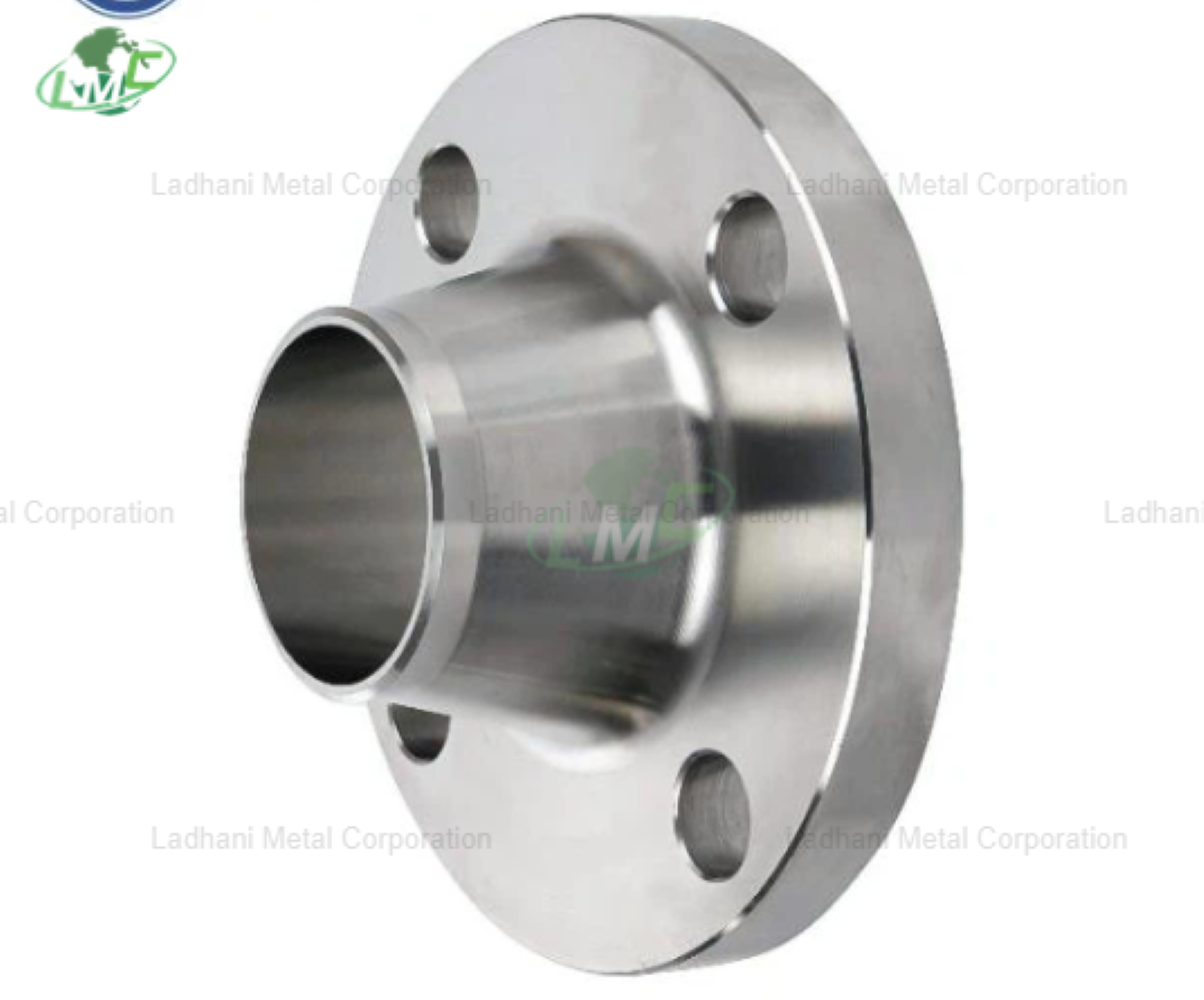

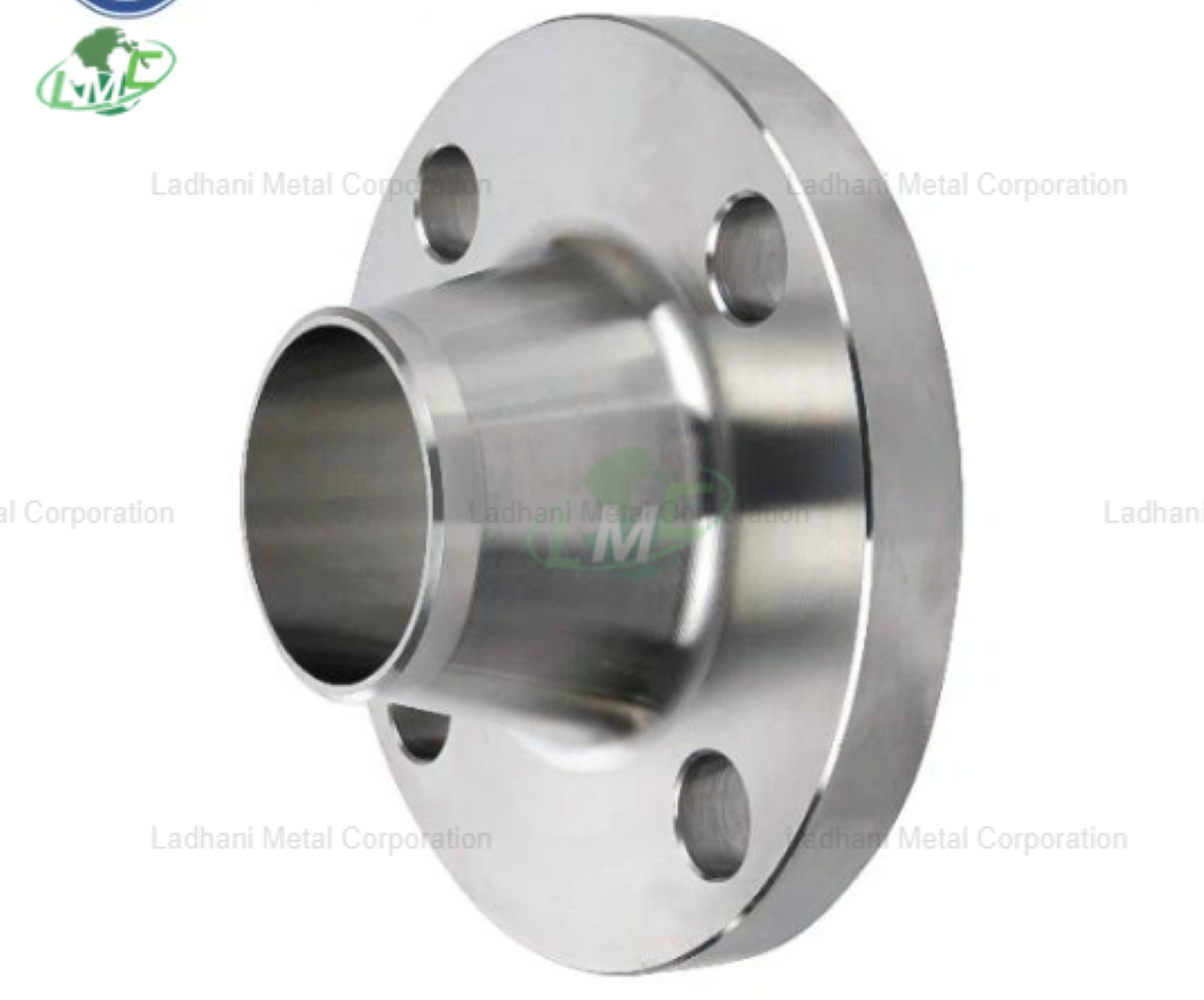

DIN 2630 Monel flanges PN 2.5 are precision-engineered weld neck flanges manufactured according to the DIN 2630 standard. These flanges are designed for low-pressure applications up to 2.5 bar (36.25 psi), offering outstanding resistance to corrosion, especially in marine and chemical environments. Fabricated from premium Monel alloys such as Monel 400 and Monel K500, these flanges provide excellent mechanical strength and durability, making them ideal for challenging service conditions in low-pressure piping systems. Ladhani Metal Corporation is a globally recognized manufacturer and supplier of Monel flanges, known for delivering high-quality products with advanced engineering precision. Our DIN 2630 PN 2.5 Monel weld neck flanges are extensively used in industries such as marine, chemical processing, oil and gas, and power generation, where superior corrosion resistance and reliability are essential. Each flange is produced to meet stringent industry standards for safety, performance, and longevity. Pressure Rating: • PN 2.5 (2.5 bar / 36.25 psi): Suitable for low-pressure applications requiring corrosion-resistant materials with excellent mechanical integrity. Flange Type: • Weld Neck Flanges Designed with a long tapered hub to enhance stress distribution and minimize turbulence, providing structural reliability and smooth fluid flow in demanding systems. • Flat Face (FF) Flanges Flat face flanges are ideal for use with cast components or soft gasket materials, ensuring uniform gasket compression in low-pressure environments. Monel Grades and Full Composition: Monel 400 (UNS N04400) • Nickel (Ni): ≥ 63.0% • Copper (Cu): 28.0 – 34.0% • Iron (Fe): 2.0 – 3.0% • Manganese (Mn): ≤ 2.0% • Silicon (Si): ≤ 0.5% • Carbon (C): ≤ 0.3% Applications: Exceptional resistance to seawater, acids, and alkalis. Widely used in marine applications, chemical and hydrocarbon processing, and heat exchangers. Monel K500 (UNS N05500) • Nickel (Ni): ≥ 63.0% • Copper (Cu): 27.0 – 33.0% • Aluminum (Al): 2.3 – 3.15% • Titanium (Ti): 0.35 – 0.85% • Iron (Fe): ≤ 2.0% • Manganese (Mn): ≤ 1.5% • Carbon (C): ≤ 0.25% Applications: Precipitation-hardened alloy offering greater strength and hardness than Monel 400 while retaining excellent corrosion resistance. Used in pump shafts, valves, and marine equipment. Applications of DIN 2630 Monel Flanges PN 2.5: • Marine Industry Ideal for use in seawater piping, heat exchangers, and ballast systems where corrosion resistance is critical. • Chemical Processing Utilized in process piping carrying corrosive chemicals and acidic media under low pressure. • Oil and Gas Industry Suitable for sour gas environments, offshore drilling platforms, and processing equipment exposed to corrosive fluids. • Power Generation Used in cooling and condensate systems where resistance to brine and steam is required. Key Features: • Manufactured in accordance with DIN 2630 standards • PN 2.5 pressure class designed for low-pressure applications • Weld neck design ensures better stress handling and flow performance • Flat face option available for uniform gasket sealing • Made from corrosion-resistant Monel 400 and Monel K500 alloys • High mechanical strength and excellent resistance to marine and chemical corrosion • Custom sizes, specifications, and finishes available upon request Conclusion: DIN 2630 Monel Flanges PN 2.5 from Ladhani Metal Corporation provide an ideal solution for low-pressure systems operating in aggressive and corrosive environments. With superior mechanical strength and outstanding resistance to seawater, acids, and other chemicals, these flanges are a reliable choice for critical applications across various industries. For custom configurations, technical consultation, or pricing details, contact Ladhani Metal Corporation.

Send Message