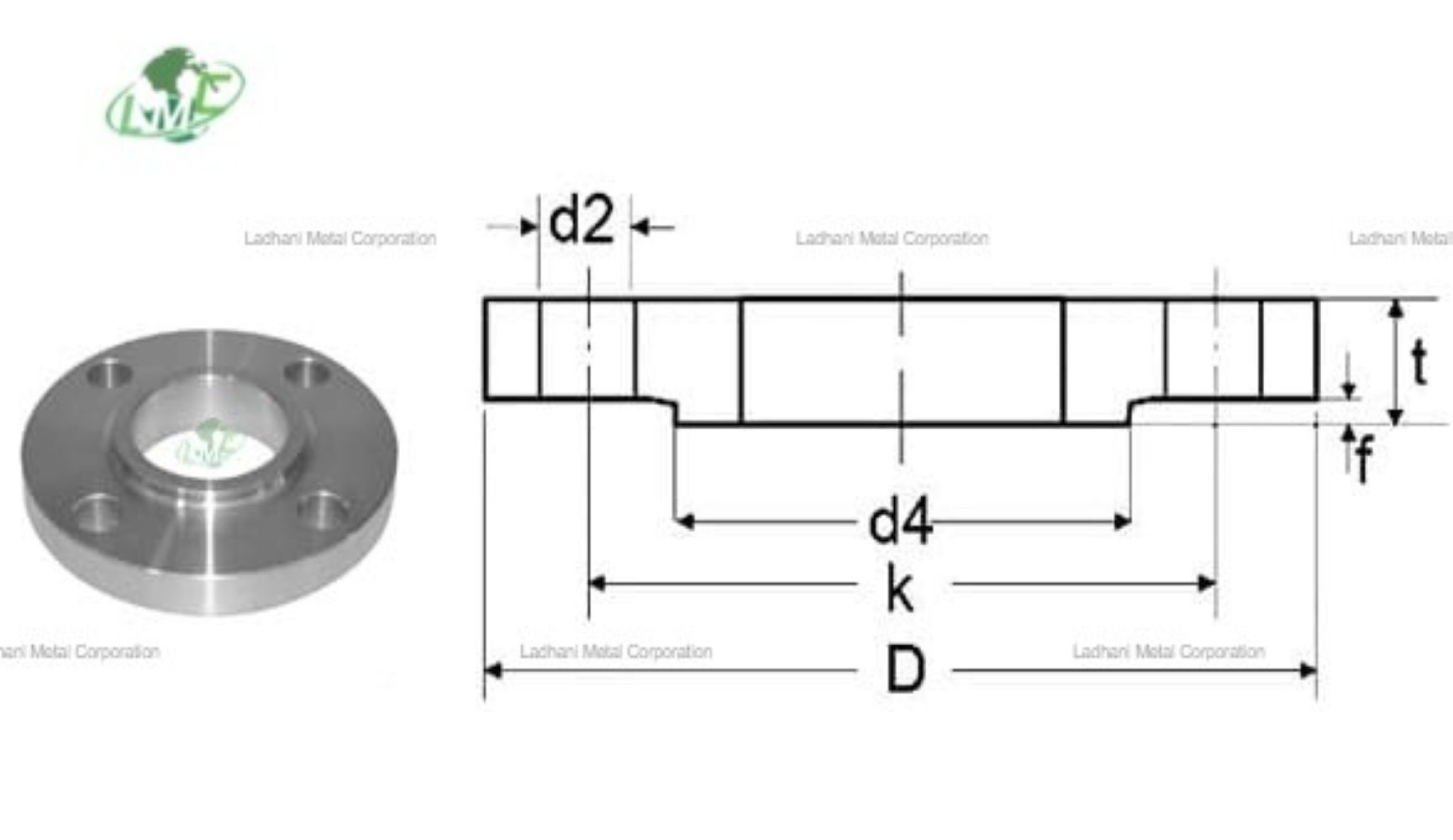

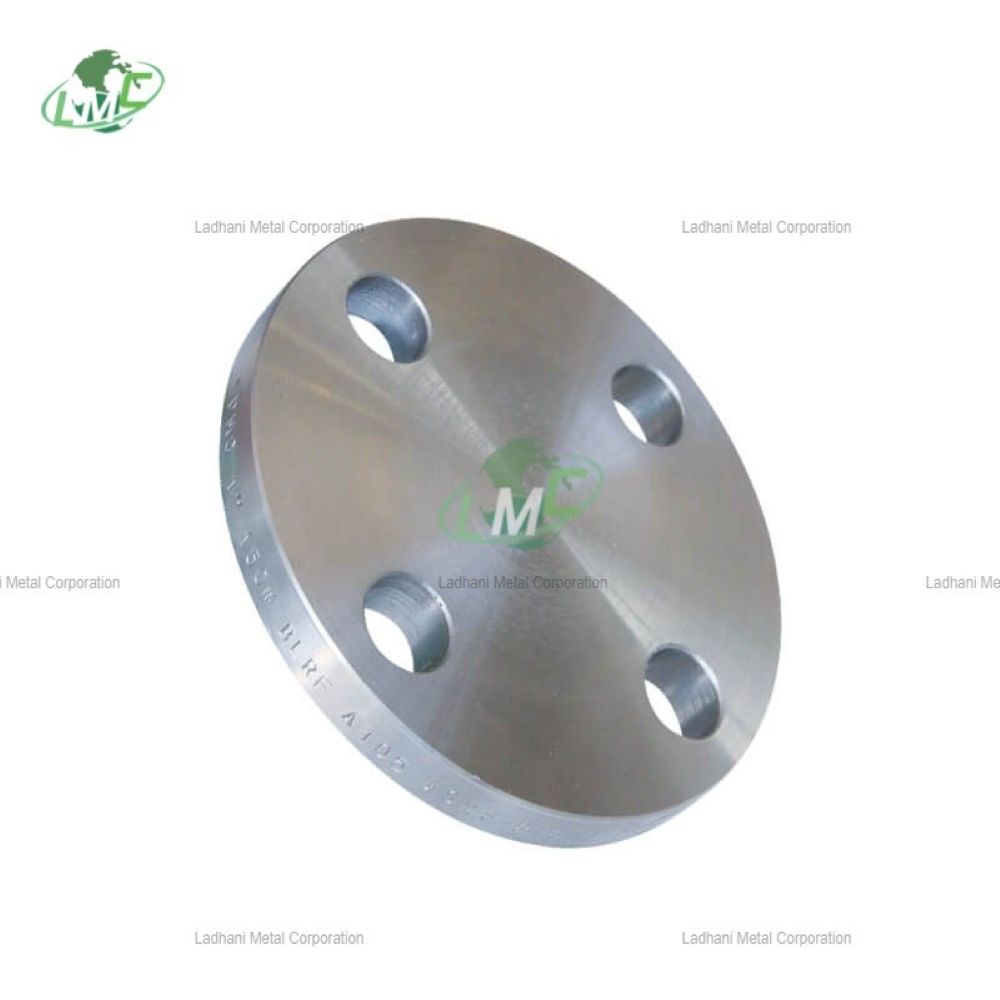

DIN 2633 duplex steel flanges PN 16 are precision-manufactured weld neck flanges designed according to the DIN 2633 standard, ideal for medium-pressure piping systems operating up to 16 bar (232 psi). These flanges are crafted from duplex stainless steels that combine the benefits of austenitic and ferritic microstructures, offering excellent mechanical strength, superior resistance to stress corrosion cracking, and enhanced durability in aggressive chemical and chloride-containing environments. They are ideal for applications where both corrosion resistance and high strength are essential. Ladhani Metal Corporation is a leading global manufacturer and supplier of duplex steel flanges, recognized for high-quality production, dimensional accuracy, and strict compliance with international standards. All flanges undergo rigorous inspection and testing to ensure reliable performance in challenging industrial conditions. Pressure Rating: • PN 16 (16 bar / 232 psi): Suitable for medium-pressure pipelines requiring corrosion resistance and increased mechanical integrity. Flange Type: • Weld Neck Flanges These flanges feature a long tapered hub for improved flow characteristics and reduced mechanical stress at the weld area, ensuring stable and secure connections. • Flat Face (FF) Flanges Designed to provide a consistent sealing surface, especially effective when used with soft gaskets or when connecting to cast components. Duplex Steel Grades and Full Composition: Duplex 2205 (UNS S31803/S32205) • Chromium (Cr): 21.0 – 23.0% • Nickel (Ni): 4.5 – 6.5% • Molybdenum (Mo): 2.5 – 3.5% • Nitrogen (N): 0.08 – 0.20% • Manganese (Mn): ≤ 2.0% • Silicon (Si): ≤ 1.0% • Carbon (C): ≤ 0.03% • Phosphorus (P): ≤ 0.03% • Sulfur (S): ≤ 0.02% • Iron (Fe): Balance Applications: Widely used in desalination plants, chemical process vessels, marine environments, and pulp and paper industries due to high strength and resistance to localized corrosion. Super Duplex 2507 (UNS S32750) • Chromium (Cr): 24.0 – 26.0% • Nickel (Ni): 6.0 – 8.0% • Molybdenum (Mo): 3.0 – 5.0% • Nitrogen (N): 0.24 – 0.32% • Manganese (Mn): ≤ 1.2% • Silicon (Si): ≤ 0.8% • Carbon (C): ≤ 0.03% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.02% • Iron (Fe): Balance Applications: Preferred in highly corrosive offshore, oil and gas, chemical, and high-chloride environments where superior strength and corrosion resistance are essential. Applications of DIN 2633 Duplex Steel Flanges PN 16: • Chemical and Petrochemical Plants Provides strong and corrosion-resistant connections for chemical reactors, storage tanks, and acid-handling systems. • Marine and Offshore Engineering Suitable for submerged systems, seawater cooling, and ballast water piping due to excellent resistance to chloride-induced corrosion. • Pulp and Paper Industry Performs reliably in bleaching and chemical recovery processes where both chemical resistance and strength are required. • Desalination and Water Treatment Ideal for high-salinity water systems and reverse osmosis pipelines requiring durable, corrosion-resistant components. • Oil and Gas Refineries Used in pipelines, pressure vessels, and heat exchangers subjected to sour gas and high-pressure operating environments. Key Features: • Manufactured to DIN 2633 standard • PN 16 pressure class for medium-pressure service • Weld neck configuration supports vibration resistance and proper alignment • Available in Duplex 2205 and Super Duplex 2507 grades • High resistance to stress corrosion cracking, pitting, and crevice corrosion • Excellent mechanical strength and fatigue resistance • Custom sizes, finishes, and specifications available upon request Conclusion: DIN 2633 duplex steel flanges PN 16 from Ladhani Metal Corporation offer an optimal combination of strength, corrosion resistance, and reliability for use in harsh industrial conditions. With high-performance duplex and super duplex materials, these flanges are the preferred choice for applications in chemical processing, offshore platforms, and desalination plants. For detailed technical support, customized configurations, or pricing, contact Ladhani Metal Corporation today.