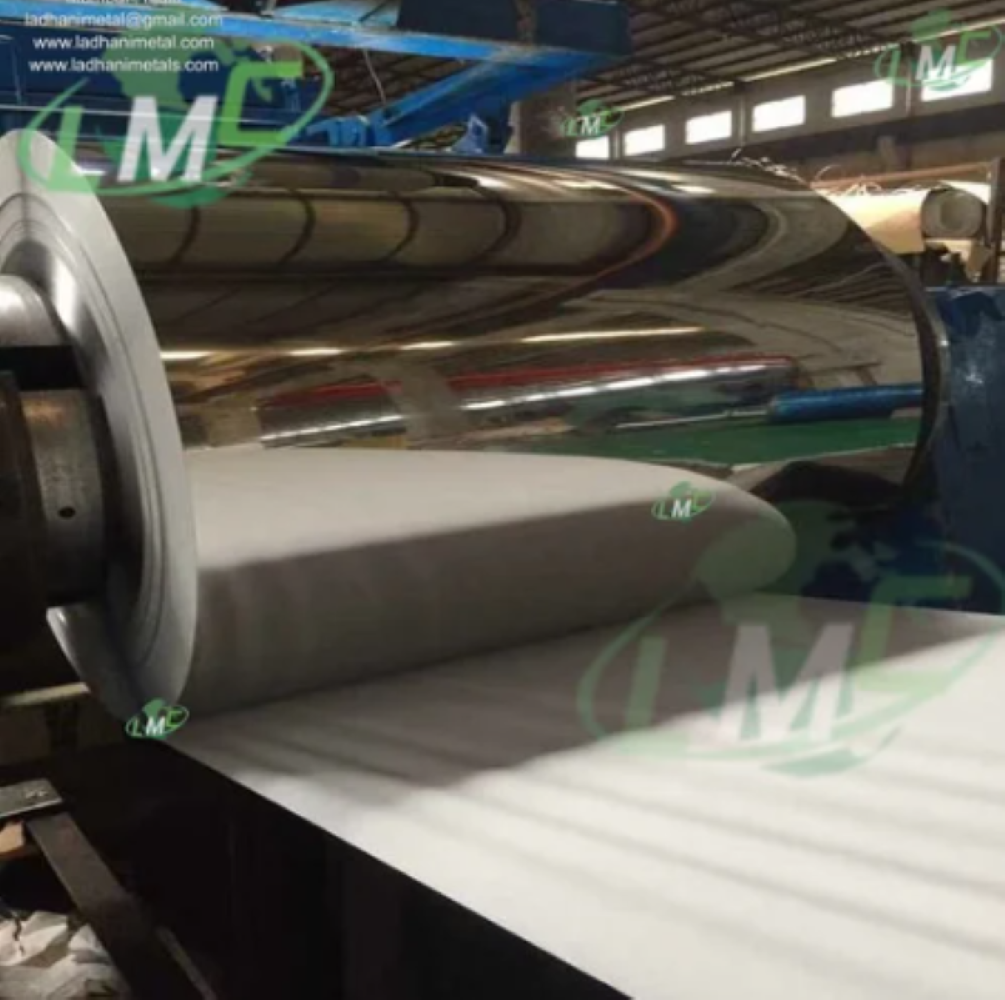

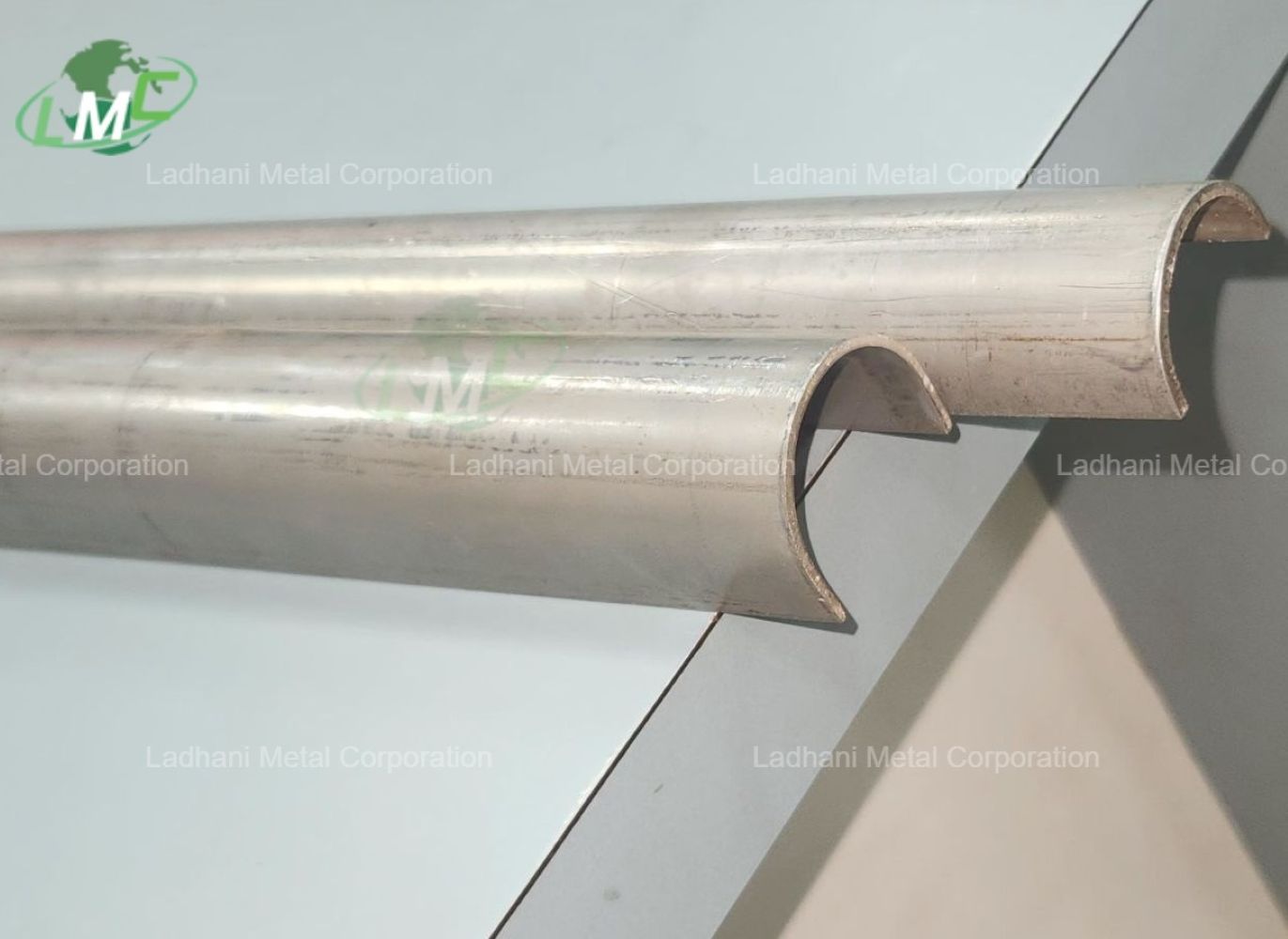

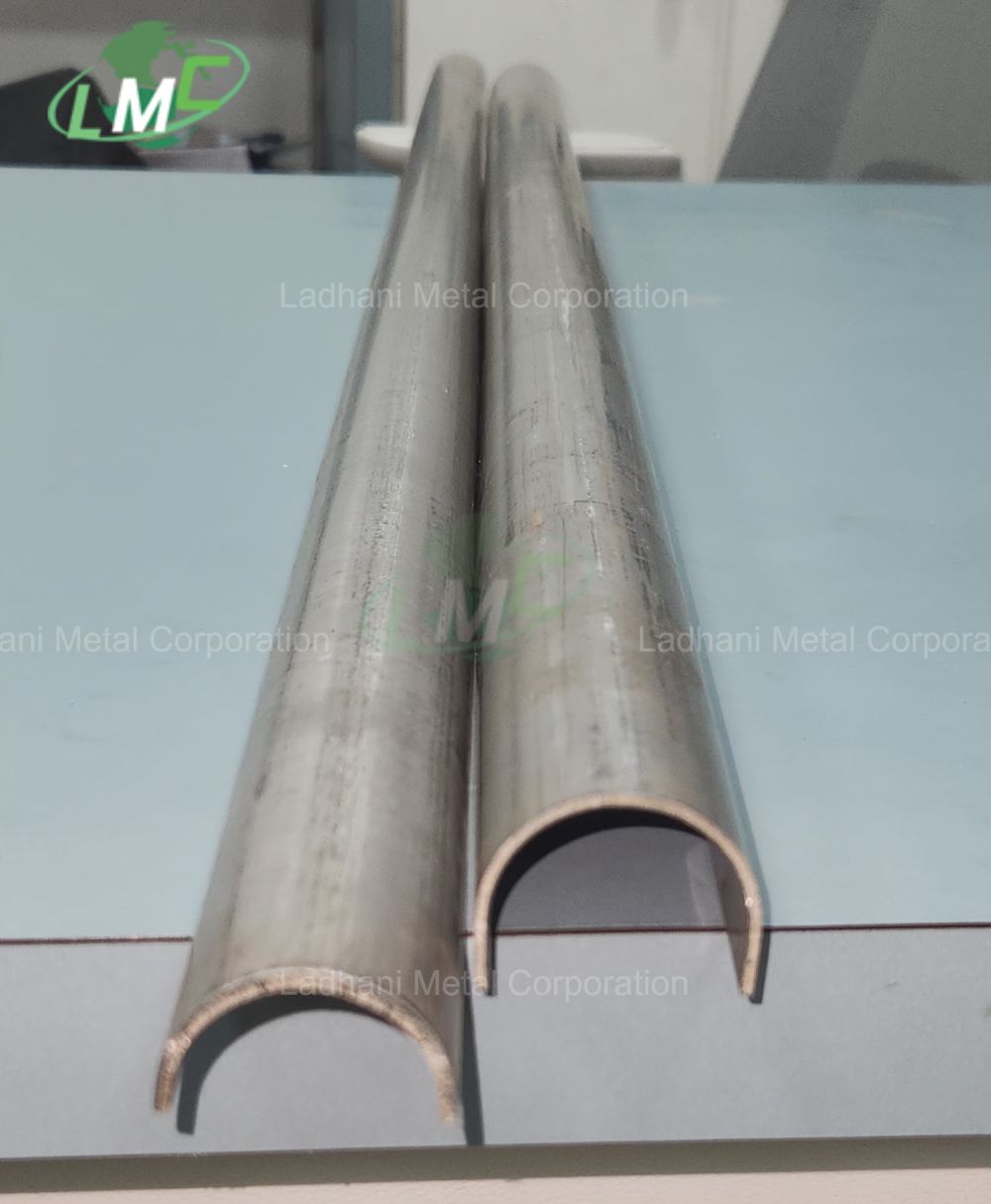

Ladhani Metal Corporation, a manufacturer, supplier, and exporter, offers stainless steel sheets, plates, and coils in grade X20Cr25Ni20 as per IS 6911 specifications. X20Cr25Ni20 is a high chromium-nickel austenitic stainless steel grade developed for superior performance at elevated temperatures. It offers outstanding resistance to oxidation, scaling, and carburization, along with good mechanical strength in aggressive industrial environments. Chemical Composition of X20Cr25Ni20 (as per IS 6911) • Carbon (C): 0.20% max • Manganese (Mn): 2.0% max • Silicon (Si): 1.0% max • Phosphorus (P): 0.045% max • Sulphur (S): 0.030% max • Chromium (Cr): 24.0% – 26.0% • Nickel (Ni): 19.0% – 22.0% Functions and Characteristics • Excellent resistance to oxidation and scaling at high temperatures • High strength retention under prolonged elevated temperature service • Superior resistance to carburization and sulfidation in aggressive atmospheres • Good corrosion resistance in oxidizing and reducing conditions • Stable austenitic microstructure ensures toughness under thermal cycling • Good formability and weldability for industrial fabrication Applications • Power Generation – Superheater tubes, reheater tubes, and boiler components • Oil and Gas – Furnace parts, flue gas handling equipment, and reformer tubes • Petrochemical Industry – Cracking units, reactors, and heat treatment fixtures • Fertilizer Plants – High-temperature vessels and chemical-handling pipelines • Chemical Industry – Heat exchangers, process reactors, and thermal equipment • Marine Engineering – Exhaust components and offshore thermal-resistant systems • Automotive Industry – Turbocharger components and exhaust manifolds • Food Processing – Thermal-resistant processing equipment and ovens • Construction – Chimney liners, refractory anchors, and high-heat structural supports • General Engineering – Valves, fasteners, and parts exposed to extreme heat Available Forms • Stainless steel sheets • Stainless steel plates • Stainless steel coils Grades Available under IS 6911 Apart from X20Cr25Ni20, IS 6911 also covers a wide range of stainless steel grades, including X04Cr12, X07Cr17, X12Cr12, X20Cr13, X30Cr13, X40Cr13, X15Cr16Ni2, X108Cr17Mo, X10Cr17Mn6Ni4N2O, X07Cr11Mn12Ni4, X10Cr18Mn9Ni5, X30Cr17Ni7, X07Cr18Ni9, X04Cr19Ni9, X02Cr19Ni10, X15Cr24Ni13, X04Cr17Ni12Mo2, X02Cr17Ni12Mo2, X04Cr17Ni12Mo2Ti, X04Cr18Ni10Ti, X04Cr18Ni10Nb and other specified grades. Conclusion IS 6911 SS X20Cr25Ni20 sheets, plates, and coils offered by Ladhani Metal Corporation, a manufacturer, supplier, and exporter, are best suited for high-temperature industrial applications requiring superior oxidation and scaling resistance. With availability in multiple IS 6911 grades, we provide reliable stainless steel solutions tailored to diverse industries. For inquiries or project requirements, contact Ladhani Metal Corporation. #Mumbai #Delhi #Chennai #Kolkata #Hyderabad #Bangalore #Pune #Ahmedabad #Surat #Rajkot #Vadodara #Coimbatore #Jaipur #Nagpur #Indore #Ludhiana #Kanpur #Bhubaneswar #Rourkela #Visakhapatnam #Trichy #Kochi #Mangalore #Jamnagar #Bharuch #Vapi #Hazira #Ankleshwar #Durgapur #Jamshedpur #Raipur #Bilaspur #Faridabad #Noida #Gurgaon #Chandigarh #Lucknow #Bhopal #Patna #Guwahati #Agra #Varanasi #Meerut #Ghaziabad #Moradabad #Aligarh #Aurangabad #Kolhapur #Nashik #Solapur #Thane #Amravati #Satara #Sangli #Hubli #Belgaum #Davangere #Mysore #Erode #Salem #Madurai #Tirunelveli #Tuticorin #Hosur #Nellore #Warangal #Karimnagar #Nanded #Udaipur #Ajmer #Jodhpur #Kota #Alwar #Gwalior #Rewa #Jhansi #IS6911sheetmanufacturer #IS6911sheet supplier # IS6911sheetexporter #IS6911 #IS6911StainlessSteel #IS6911Sheet #IS6911Plate #IS6911Coil #IS6911Strip #IS6911Manufacturer #IS6911Supplier #IS6911Exporter #StainlessSteelIndia #StainlessSteelSheet #StainlessSteelPlate #StainlessSteelCoil #StainlessSteelStrip #SS304 #SS304L #SS316 #SS316L #X04Cr12 #X07Cr17 #X12Cr12 #X20Cr13 #X30Cr13 #X40Cr13 #X15Cr16Ni2 #X108Cr17Mo #X07Cr18Ni9 #X04Cr19Ni9 #X02Cr19Ni10 #X15Cr24Ni13 #X20Cr25Ni20 #X04Cr17Ni12Mo2 #X02Cr17Ni12Mo2 #X04Cr17Ni12Mo2Ti #X04Cr18Ni10Ti #X04Cr18Ni10Nb #StainlessSteelGrades #StainlessSteelManufacturer #StainlessSteelSupplier #StainlessSteelExporter #StainlessSteelStockist #IndustrialStainlessSteel #BoilerStainlessSteel #PetrochemicalStainlessSteel #ChemicalIndustryStainlessSteel #MarineStainlessSteel #HeatResistantSteel #CorrosionResistantSteel #SSSheetsPlatesCoils #LadhaniMetalCorporation

Send Message