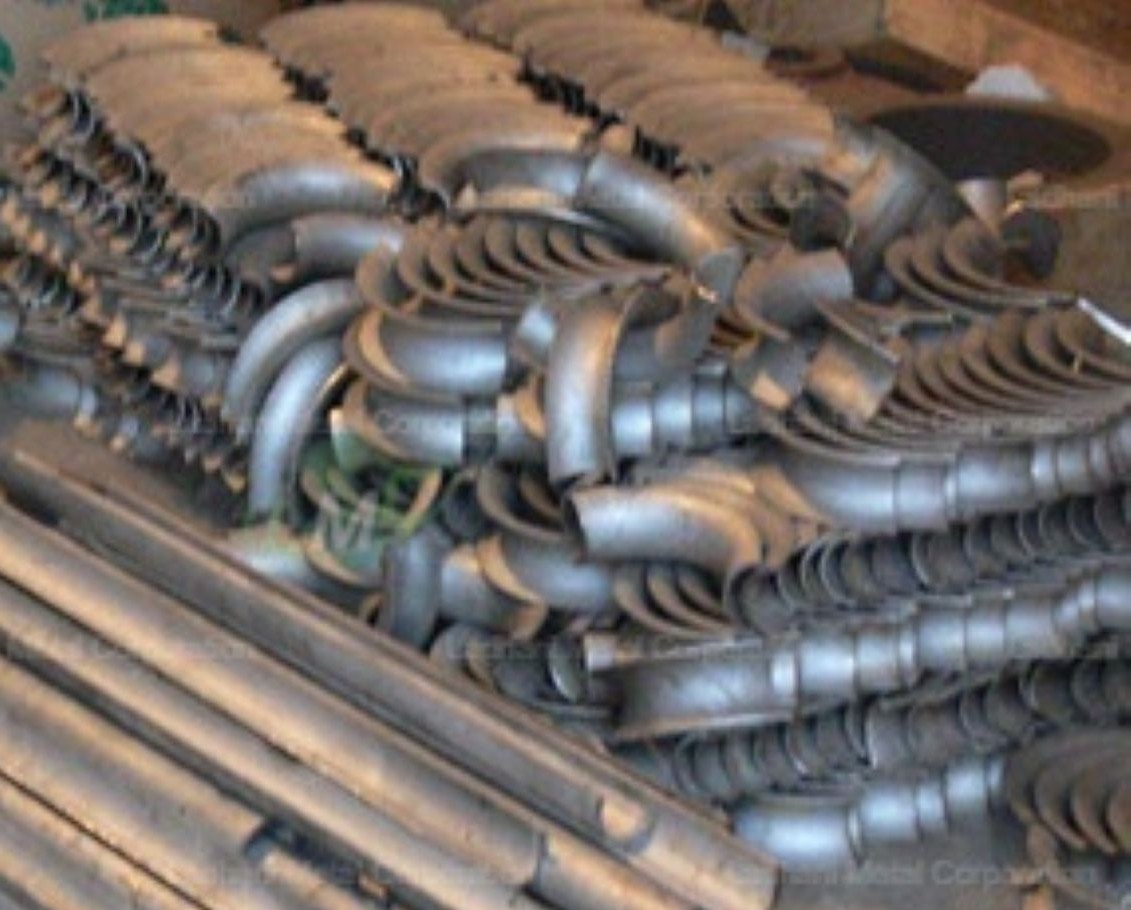

Ladhani Metal Corporation offers 1Cr13 Outer Half Round 90 Degree Bend Tube Shields engineered to provide robust protection for the outer arc of U-bends and 90-degree tube turns in boilers, heat exchangers, superheaters, reheaters, and industrial furnaces. The semi-cylindrical profile is precisely formed to conform to the curvature of return tube bends, acting as a physical shield against flue gas erosion, soot blower impact, and ash particle abrasion. These shields are well-suited for use in thermal power plants, utility boilers, waste heat recovery systems, and industrial heaters where mechanical protection is critical. Ladhani Metal Corporation is a dependable manufacturer, supplier, and exporter of 1Cr13 Outer Half Round 90 Degree Bend Tube Shields, offering custom-made options to meet specific plant and system requirements. 1Cr13 Grade Chemical Composition – Martensitic Stainless Steel • Carbon (C): 0.15 – 0.20% • Manganese (Mn): ≤ 1.00% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 12.0 – 14.0% • Nickel (Ni): ≤ 0.60% • Iron (Fe): Balance Applications: Ideal for dry flue gas systems, high-velocity ducting, and thermal processing equipment where resistance to wear and moderate oxidation is essential. Uses • Protects 90-degree bends in superheaters and reheaters from mechanical erosion • Applied in WHRBs, HRSGs, and industrial furnaces under dry service conditions • Shields tube curves from flue gas abrasion, ash particle impact, and soot blower blasts • Used in exhaust systems and ducting where moderate corrosion resistance is sufficient Features • High wear resistance – Withstands mechanical damage from ash and particulate flow • Moderate oxidation resistance – Performs well in dry, non-aggressive gas environments • Structural strength – Maintains rigidity and protection under high mechanical stress • Precision fit – Formed to match exact bend radii for effective coverage • Easy to install – Can be clamped, tack welded, or banded based on operational needs • Size flexibility – Available in a range of lengths, thicknesses, and diameters for tailored application Applications • Power and utility boilers – Shields return bends from soot erosion and surface damage • Waste heat recovery units – Protects tube bends in clean and dry gas systems • Industrial furnaces – Applied in zones with high particulate flow and moderate heat exposure • Petrochemical and cement plants – Guards high-wear tube bends from abrasive gas streams Conclusion The 1Cr13 Outer Half Round 90 Degree Bend Tube Shield by Ladhani Metal Corporation offers durable and cost-effective protection for tube bends operating in dry, high-velocity, and mildly corrosive environments. Its mechanical strength and resistance to erosion make it a practical solution for extending the service life of critical tube components. For tailored solutions, technical consultation, or sizing requirements, contact Ladhani Metal Corporation. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Salem #Erode #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Hassan #Cuttack #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Gaya #Muzaffarpur #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #halftubeshield #utypehalftubeshield #tubeshieldexporter

Send Message