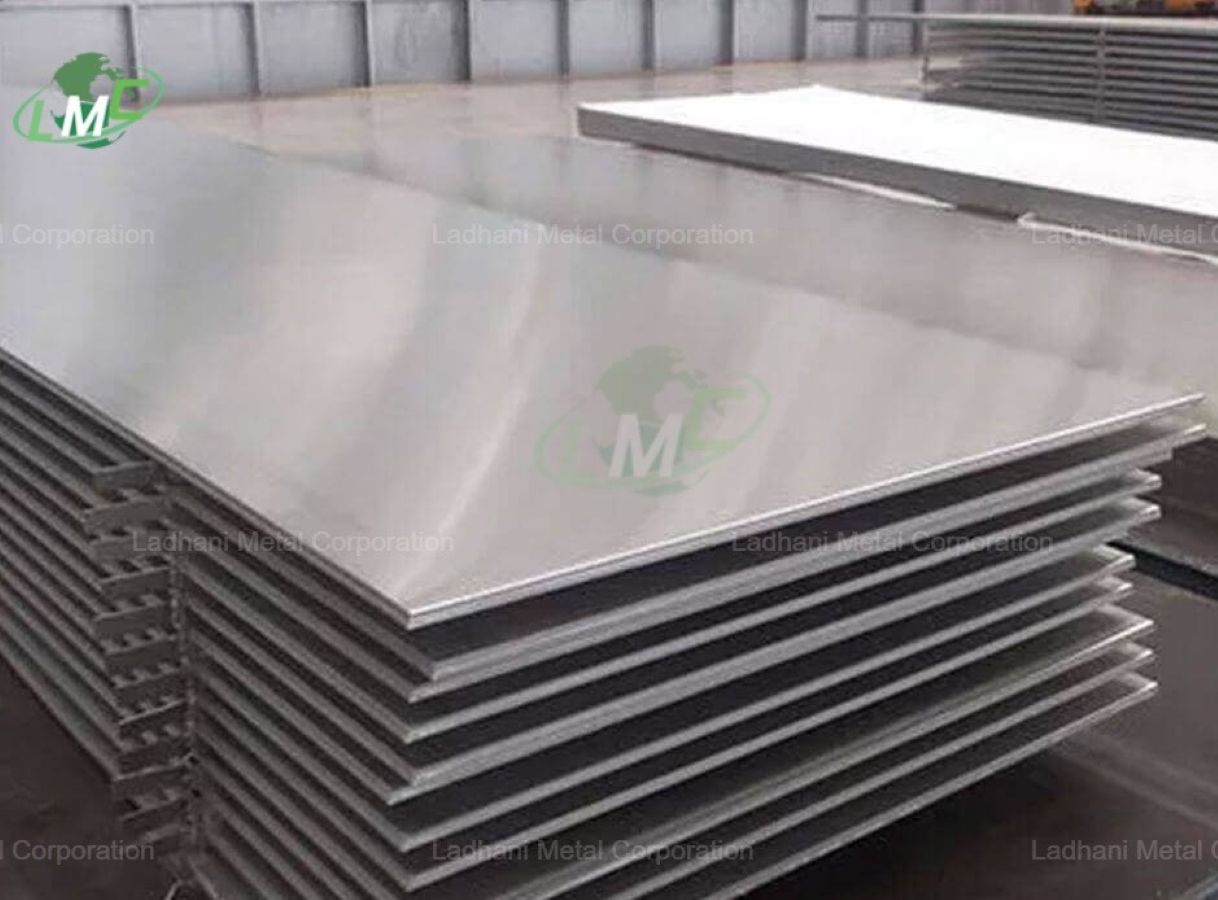

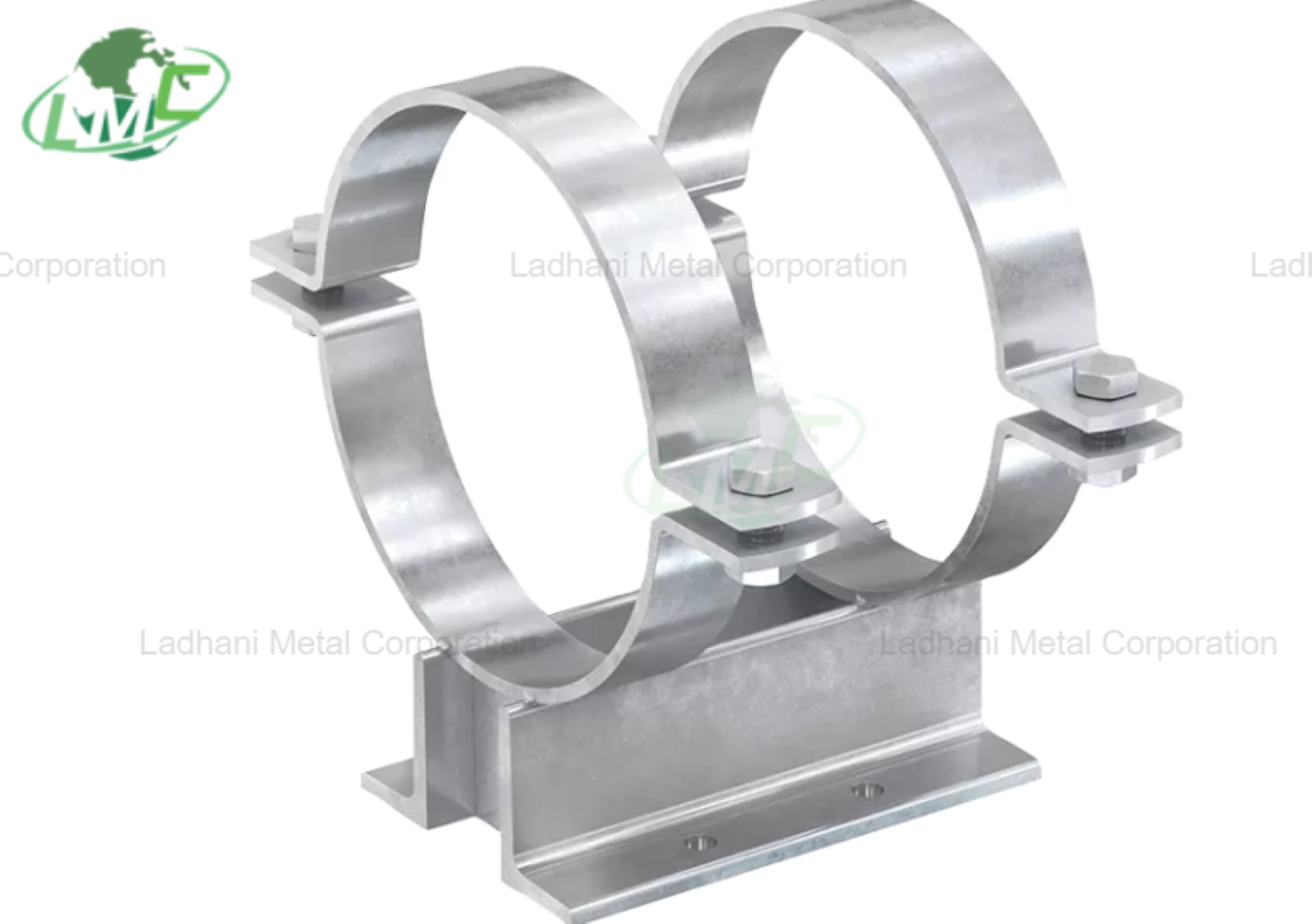

Ladhani Metal Corporation, a manufacturer, supplier, and exporter, offers stainless steel sheets, plates, and coils in grade X07Cr11Mn12Ni4 as per IS 6911 specifications. X07Cr11Mn12Ni4 is an austenitic stainless steel grade with high manganese and nickel content, designed to provide superior toughness, excellent wear resistance, and good corrosion resistance. Its unique chemical balance allows it to perform well in demanding environments where both mechanical strength and durability are essential. Chemical Composition of X07Cr11Mn12Ni4 (as per IS 6911) • Carbon (C): 0.07% max • Manganese (Mn): 11.0% – 13.0% • Silicon (Si): 1.0% max • Phosphorus (P): 0.040% max • Sulphur (S): 0.030% max • Chromium (Cr): 10.0% – 12.5% • Nickel (Ni): 3.5% – 5.0% Functions and Characteristics • High manganese content ensures excellent toughness and wear resistance • Provides fair corrosion resistance in mildly aggressive environments • Non-magnetic in the annealed condition, magnetic when cold-worked • Good machinability and formability for industrial components • Offers a balance of strength, ductility, and durability Applications • Power Generation – Wear-resistant turbine and boiler components • Oil and Gas – Transmission parts, pipelines, and offshore equipment • Petrochemical Industry – Reactor parts, valves, and process machinery • Fertilizer Plants – Equipment exposed to chemical wear and corrosion • Chemical Industry – Heat exchangers, process vessels, and tanks • Marine Engineering – Shipbuilding, seawater systems, and rig components • Automotive Industry – Wear-resistant parts, clamps, and engine components • Food Processing – Equipment requiring both hygiene and wear resistance • Construction – Structural components and heavy-duty fasteners • General Engineering – Shafts, machine parts, and wear-resistant tools Available Forms • Stainless steel sheets • Stainless steel plates • Stainless steel coils Grades Available under IS 6911 Apart from X07Cr11Mn12Ni4, IS 6911 also covers a wide range of stainless steel grades, including X04Cr12, X07Cr17, X12Cr12, X20Cr13, X30Cr13, X40Cr13, X15Cr16Ni2, X108Cr17Mo, X10Cr17Mn6Ni4N2O, X10Cr18Mn9Ni5, X30Cr17Ni7, X07Cr18Ni9, X04Cr19Ni9, X02Cr19Ni10, X15Cr24Ni13, X20Cr25Ni20, X04Cr17Ni12Mo2, X02Cr17Ni12Mo2, X04Cr17Ni12Mo2Ti, X04Cr18Ni10Ti, X04Cr18Ni10Nb and other specified grades. Conclusion IS 6911 SS X07Cr11Mn12Ni4 sheets, plates, and coils offered by Ladhani Metal Corporation, a manufacturer, supplier, and exporter, combine wear resistance, toughness, and fair corrosion resistance for demanding engineering applications. With availability in multiple grades as per IS 6911, we provide reliable stainless steel solutions that meet both domestic and international standards. For inquiries or project requirements, contact Ladhani Metal Corporation. #Mumbai #Delhi #Chennai #Kolkata #Hyderabad #Bangalore #Pune #Ahmedabad #Surat #Rajkot #Vadodara #Coimbatore #Jaipur #Nagpur #Indore #Ludhiana #Kanpur #Bhubaneswar #Rourkela #Visakhapatnam #Trichy #Kochi #Mangalore #Jamnagar #Bharuch #Vapi #Hazira #Ankleshwar #Durgapur #Jamshedpur #Raipur #Bilaspur #Faridabad #Noida #Gurgaon #Chandigarh #Lucknow #Bhopal #Patna #Guwahati #Agra #Varanasi #Meerut #Ghaziabad #Moradabad #Aligarh #Aurangabad #Kolhapur #Nashik #Solapur #Thane #Amravati #Satara #Sangli #Hubli #Belgaum #Davangere #Mysore #Erode #Salem #Madurai #Tirunelveli #Tuticorin #Hosur #Nellore #Warangal #Karimnagar #Nanded #Udaipur #Ajmer #Jodhpur #Kota #Alwar #Gwalior #Rewa #Jhansi #IS6911sheetmanufacturer #IS6911sheet supplier # IS6911sheetexporter #IS6911 #IS6911StainlessSteel #IS6911Sheet #IS6911Plate #IS6911Coil #IS6911Strip #IS6911Manufacturer #IS6911Supplier #IS6911Exporter #StainlessSteelIndia #StainlessSteelSheet #StainlessSteelPlate #StainlessSteelCoil #StainlessSteelStrip #SS304 #SS304L #SS316 #SS316L #X04Cr12 #X07Cr17 #X12Cr12 #X20Cr13 #X30Cr13 #X40Cr13 #X15Cr16Ni2 #X108Cr17Mo #X07Cr18Ni9 #X04Cr19Ni9 #X02Cr19Ni10 #X15Cr24Ni13 #X20Cr25Ni20 #X04Cr17Ni12Mo2 #X02Cr17Ni12Mo2 #X04Cr17Ni12Mo2Ti #X04Cr18Ni10Ti #X04Cr18Ni10Nb #StainlessSteelGrades #StainlessSteelManufacturer #StainlessSteelSupplier #StainlessSteelExporter #StainlessSteelStockist #IndustrialStainlessSteel #BoilerStainlessSteel #PetrochemicalStainlessSteel #ChemicalIndustryStainlessSteel #MarineStainlessSteel #HeatResistantSteel #CorrosionResistantSteel #SSSheetsPlatesCoils #LadhaniMetalCorporation

Send Message