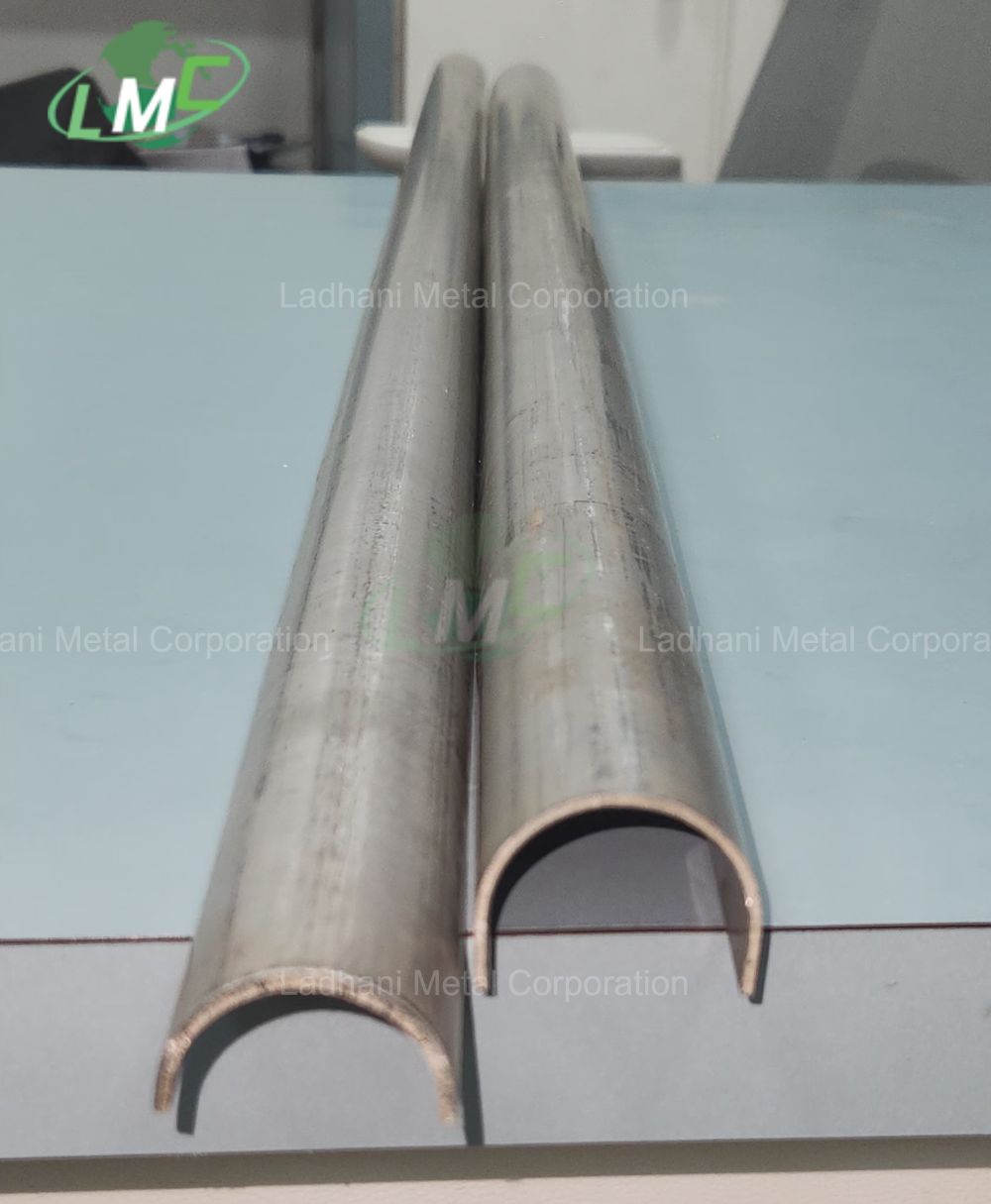

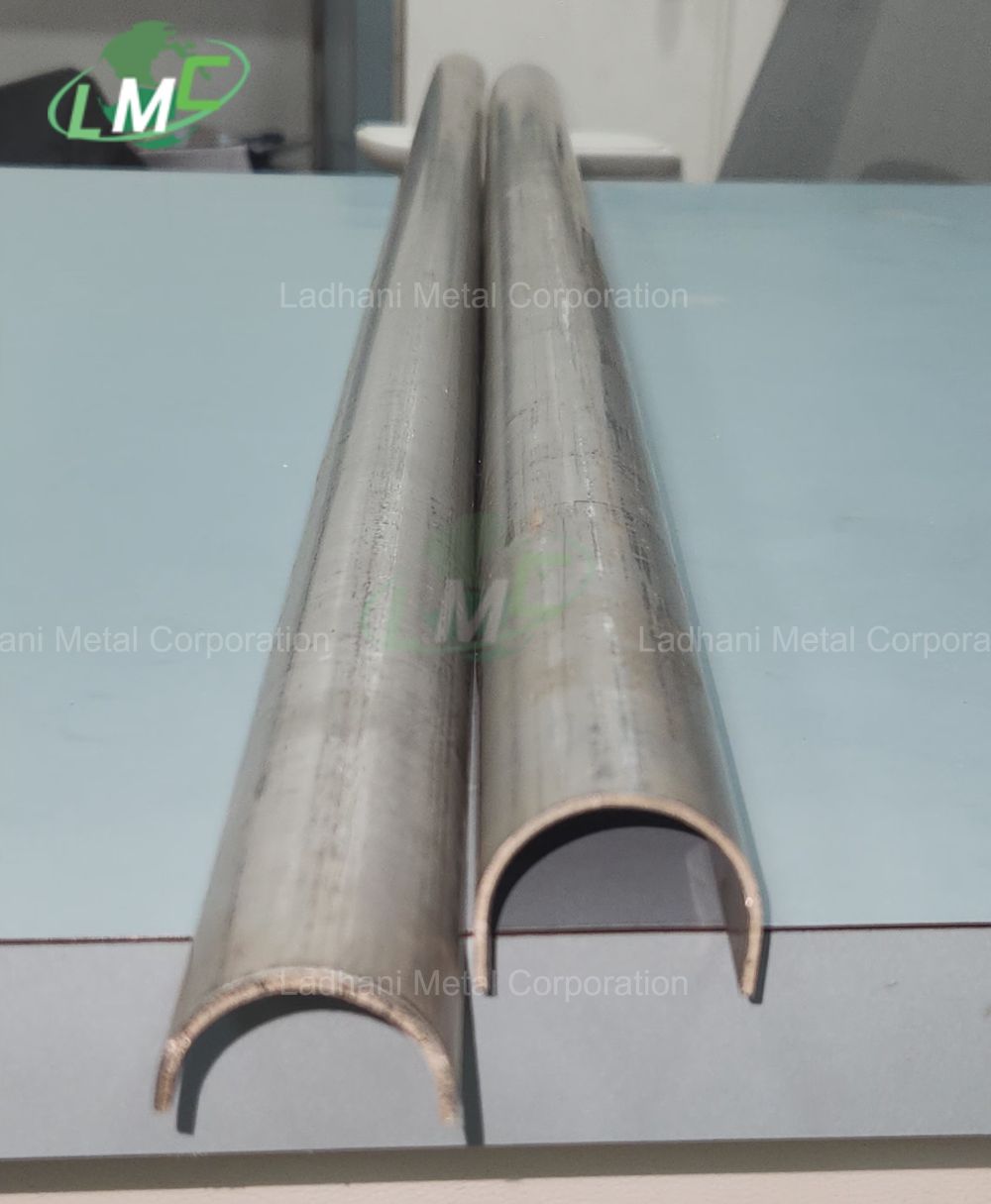

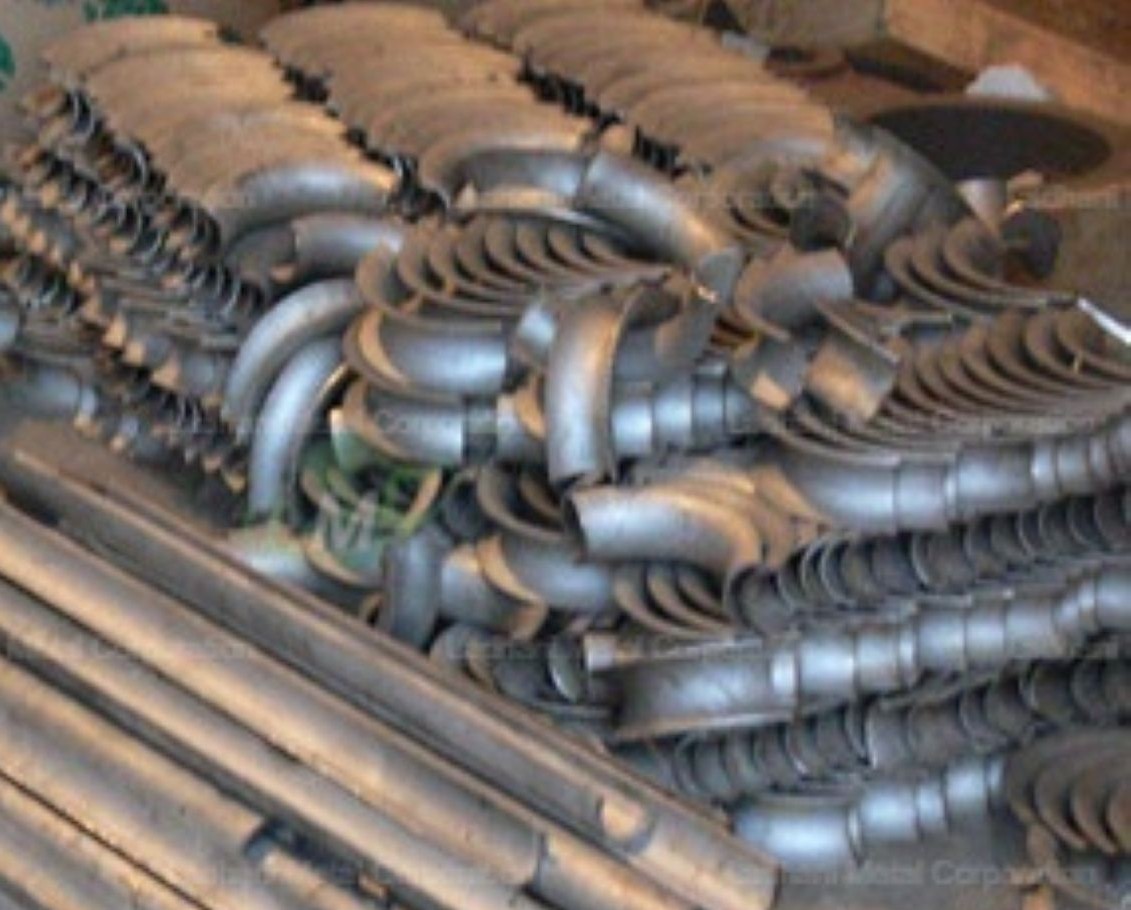

Metal Corporation offers SS Half Round Boiler Tube Covers designed to protect boiler tubes in high-temperature, erosive, and oxidizing environments. These semi-cylindrical covers act as a shield against soot blower impact, abrasive flue gas particles, scaling, and surface oxidation. Extensively used in superheaters, reheaters, economizers, and waste heat recovery boilers, SS Half Round Boiler Tube Covers extend service life, reduce tube damage, and ensure reliable boiler performance. Function of SS Half Round Boiler Tube Covers • Provide effective protection against erosion, oxidation, and scaling • Minimize localized wear in high-flue-gas velocity and ash-laden zones • Extend the operational life of boiler tubes, reducing costly downtime • Improve efficiency and reliability of boilers under harsh service conditions Ladhani Metal Corporation manufactures, supplies, and exports SS Half Round Boiler Tube Covers in multiple grades, thicknesses, and custom radii, catering to both domestic and international boiler systems. Available Grades • SS 304 / SS 304L • SS 310 / SS 310S • SS 316 / SS 316L • SS 410 / SS 420 / SS 430 • 1Cr13 • 1Cr18Ni9Ti • 1Cr20Ni14Si2 • 1Cr25Ni20Si2 • Cr23Ni13 • Cr25Ni20 Applications: Well-suited for power generation boilers, WHRBs, HRSGs, refinery heaters, and industrial process boilers operating under oxidizing and erosive conditions. Uses • Protects superheater and reheater tubes from soot blower erosion • Shields economizer tubes against abrasive flue gas streams • Extends service life of boiler components under continuous high temperatures • Reduces maintenance needs and replacement costs in critical boiler zones Features • Excellent high-temperature resistance to oxidation and scaling • Strong mechanical durability under cyclic thermal stress • Precision-engineered fit for reliable tube coverage • Easy to install, replace, and maintain during shutdowns Applications • Thermal power plants – Protection for reheater and superheater sections • Waste heat recovery boilers – Guards tubes from abrasive gas flows • HRSGs – Reliable in cyclic heating and cooling operations • Refinery and petrochemical heaters – Provides durability in corrosive atmospheres Conclusion SS Half Round Boiler Tube Covers by Ladhani Metal Corporation are engineered for superior protection of boiler tubes against erosion, oxidation, and scaling. Available in a wide range of stainless steels and special heat-resistant alloys, these covers deliver export-quality performance, long service life, and reliable operation for critical boiler applications worldwide. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Muzaffarpur#halftubeshield #utypehalftubeshield #tubeshieldexporter #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #HalfRoundReheaterShield #ReheaterTubeShield #BoilerReheaterProtection #PowerPlantTubeShield #BoilerErosionShield #SteamBoilerTubeShield #HighTempTubeShield #BoilerWearProtection

Send Message