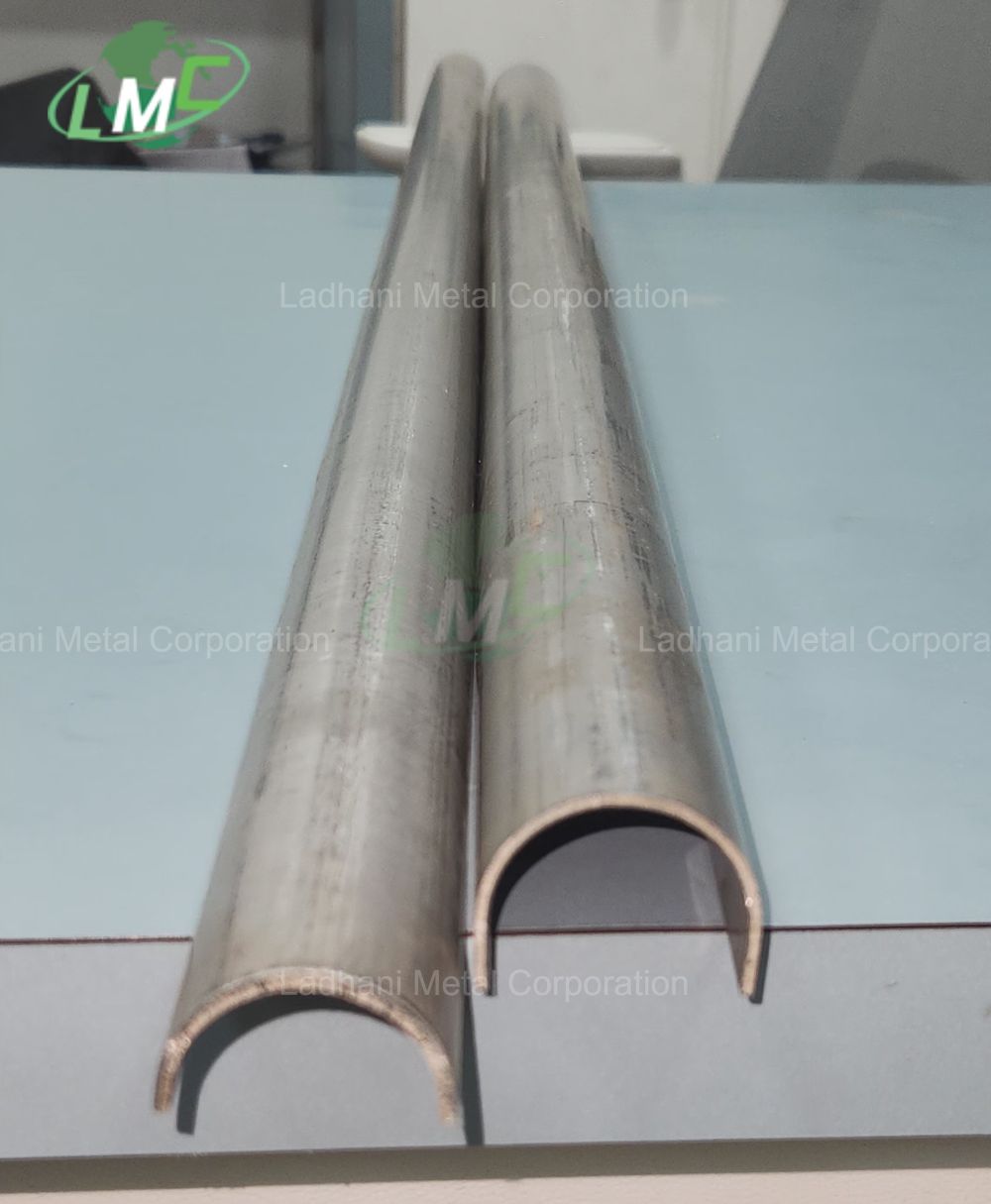

Product name: Gr2 Titanium Tubes 25.4mm

Standard:ASTM B338

Material:Titanium Gr2

Diameter:5-914mm

Wall thickness:0.5-10mm

Length:Max 16000mm

Surface:Pickling surface/Polished

Type:Seamless, welded

Application:Heat Exchanger, chemical industry etc.

Technique:Rolled

Gr2 Titanium Tubes 25.4mm

Titanium pipe/titanium alloy pipe has excellent strength, hardness, small density, light weight, high temperature resistance, low temperature resistance, good machining performance, excellent corrosion resistance, non-magnetic non-toxic, good heat exchange performance. It also has memory and superconductivity. Hydrogen storage performance is very outstanding, the products are widely used in: navigation, aerospace, vacuum salt, automotive industry, medical sports, paper and textile industry, electric power industry, metallurgy industry, chlor-alkali industry, chemical fertilizer industry, seawater desalination industry.

1.Shape: round tube, square tube, spiral tube, coil tube,

2. Standard: ASTM B337, ASTM B338, ASTM B861, ASTM B862

3. Srand: Titanium GR2

4. Specifications:

ф (3-159) x (0.2-10.0) x L(500-9000)

ф (30-1000) x (0.5-12.0) x L(500-15000)

Extruded tube (M state) ф (45-219) x (5.0-30.0) x L

5. Production method: cold rolling, extrusion

6. Testing: ultrasonic testing, eddy current testing, water pressure testing, airtight testing

LADHANI METAL CORPORATION, MUMBAI, INDIA

Company Information

Ladhani Metal Corporation.

We are committed to integrate engineering steel resources in India and serve the global engineering steel market. Our company has more than 32 years of experience in steel researching, production, managing and sales.

In the aspect of resources and information, we have established cooperative and stronger relationship with nearly hundred enterprises, either state-owned or private owned in India.

What’s more, we have built long, deep and close business relationship with dozens of steel company, Sharing and holding equities with several steel enterprises. Because of the close cooperation with steel companies and our pioneering spirit, which can ensure us stay at the top competition, and ensure our customers get what they really want!

FOR MORE DETAIL CONTACT US AT :-

ladhanimetal@gmail.com

ladhanimetals@gmail.com

www.ladhanimetal.in

www.ladhanimetal.com

LADHANI METAL CORPORATION, MUMABAI, INDIA,

AVAILABLE AT FOLLOWING LOCATION:-

Adilabad, Agartala, Agra, Ahmedabad, Ahmednagar, Ajmer, Akola , Aligarh , Alipore , Allahabad , Alleppey , Almora , Alwar , Alwaye , Amalapuram , Amaravati , Ambala , Amreli , Amritsar , Anakapalle , Anand , Anantapur , Andhra Pradesh , Anna Road , Arakkonam , Arunachal Pradesh , Asansol , Aska , Assam , Aurangabad , Azamgarh , Bagalkot , Bahraich , Balaghat , Balangir , Balasore , Ballia , Banasanktha , Banda , Bangalore , Bankura , Barabanki , Barabazaar , Baramulla , Barasat , Bardoli , Bareilly , Barmer , Bastar , Basti , Beawar , Beed , Begusarai , Belgaum , Bellary , Berhampur , Bhadrak , Bhagalpur , Bharatpur , Bharuch , Bhatinda , Bhavnagar , Bhilwara , Bhimavaram , Bhiwani , Bhojpur , Bhopal , Bhubaneswar , Bhusaval , Bidar , Bihar , Bijapur , Bijnor , Bikaner , Bilaspur , Birbhum , Budaun , Bulandshahar , Buldana , Burdwan , Cachar , Calcutta , Calicut , Cannanore , Chamba , Chamoli , Chandigarh , Chandrapur , Changanacherry , Channapatna , Chattisgarh , Chengalpattu , Chennai , Chhatarpur , Chhindwara , Chikmagalur , Chikodi , Chitradurga , Chittoor , Chittorgarh , Churu , Coimbatore , Contai , Cooch Behar , Cuddalore , Cuddapah , Cuttack , Darbhanga , Darjeeling , Darrang , Dehra Gopipur , Dehradun , Delhi , Delhi , Deoria , Dhanbad , Dharamsala , Dharmanagar , Dharmapuri , Dharwad , Dhenkanal , Dholpur , Dhule , Dibrugarh , Dinajpur , Dindigul , divisionname , Dungarpur , Durg , Eluru , Ernakulam , Erode , Etah , Etawah , Faizabad , Faridabad , Faridkot , Fatehgarh , Fatehpur , Ferozpur , Gadag , Gandhinagar , Gaya , Ghaziabad , Ghazipur , Giridih , Goa , Goalpara , Gokak , Gonda , Gondal , Gorakhpur , Gudivada , Gudur , Gujarat , Gulbarga , Guna , Guntur , Gurdaspur , Gurgaon , Guwahati , Gwalior , Hamirpur , Hanamkonda , Hardoi , Haryana , Hassan , Haveri , Hazaribagh , Himachal Pradesh , Hindupur , Hissar , Hooghly , Hoshangabad , Hoshiarpur , Howrah , Hyderabad , Idukki , Indore , Irinjalakuda , Jabalpur , Jaipur , Jalandhar , Jalgaon , Jalpaiguri , Jammu , Jammu kashmir , Jamnagar , Jaunpur , Jhansi , Jharkhand , Jhunjhunu , Jodhpur , Junagadh , Kakinada , Kalahandi , Kanchipuram , Kanniyakumari , Kanpur , Kapurthala , Karaikudi , Karimnagar , Karnal , Karnataka , Karur , Karwar , Kasaragod , Keonjhar , Kerala , Khammam , Khandwa , Kheda , Kheri , Kodagu , Kolar , Kolhapur , Kolkata , Koraput , Kota , Kottayam , Kovilpatti , Krishnagiri , Kumbakonam , Kurnool , Kurukshetra , Kutch , Lakshadweep , Leh , Lucknow , Ludhiana , Machilipatnam , Madhubani , Madhya Pradesh , Madurai , Mahabubnagar , Maharashtra , Mahesana , Mainpuri , Malda , Malegaon , Mandi , Mandsaur , Mandya , Mangalore , Manipur , Manjeri , Mathura , Mavelikara , Mayiladuthurai , Mayurbhanj , Medak , Meerut , Meghalaya , Midnapore , Mirzapur , Mizoram , Monghyr , Moradabad , Morena , Mumbai , Murshidabad , Muzaffarnagar , Muzaffarpur , Mysore , Nadia , Nagaland , Nagaon , Nagapattinam , Nagaur , Nagpur , Nainital , Nalanda , Nalbari , Nalgonda , Namakkal , Nanded , Nandyal , Nanjangud , Narasaraopet , Nasik , Navsari , Nawadha , Nellore , New Delhi , New Mumbai , Nilgiris , Nizamabad , North Eastern , Odisha , Osmanabad , Ottapalam , Palamau , Palghat , Pali , Panchmahals , Pandharpur , Parvathipuram , Patan , Pathanamthitta , Patiala , Patna , Pattukottai , Pauri , Peddapalli , Pharbhani , Phulbani , Pithoragarh , Pollachi , Pondicherry , Porbandar , Prakasam , Pratapgarh , Proddatur , Pudukkottai , Pune , Punjab , Puri , Purnea , Purulia , Puttur , Quilon , Rae Bareilly , Raichur , Raigad , Raigarh , Raipur , Rajahmundry , Rajasthan , Rajkot , Rajouri , Ramanathapuram , Rampur Bushahr , Ranchi , Ratlam , Ratnagiri , Rewa , Rohtak , Rohtas , Sabarkantha , Sagar , Saharanpur , Saharsa , Salem , Samastipur , Sambalpur , Sangareddy , Sangli , Sangrur , Santhal Parganas , Saran , Satara , Sawaimadhopur , Secunderabad , Sehore , Shahdol , Shahjahanpur , Shimla , Shimoga , Shrirampur , Sibsagar , Sikar , Sikkim , Sindhudurg , Singhbhum , Sirohi , Sirsi , Sitamarhi , Sitapur , Sivaganga , Siwan , Solan , Solapur , Sonepat , Sriganganagar , Srikakulam , Srinagar , Srirangam , Sultanpur , Sundargarh , Surat , Surendranagar , Suryapet , Tadepalligudem , Tambaram , Tamilnadu , Tamluk , Tehri , Tenali , Thalassery , Thane , Thanjavur , Theni , Tinsukia , Tiruchirapalli , Tirunelveli , Tirupati , Tirupattur , Tirupur , Tirur , Tiruvalla , Tiruvannamalai , Tonk , Trichur , Trivandrum , Tumkur , Tuticorin , Udaipur , Udhampur , Udupi , Ujjain , Una , Uttar Pradesh , Uttarakhand , Vadakara , Vadodara , Vaishali , Valsad , Varanasi , Vellore , Vidisha , Vijayawada , Virudhunagar , Visakhapatnam , Vizianagaram , Vriddhachalam , Wanaparthy , Warangal , Wardha , West Bengal , Yeotmal , Bangalore , Hyderabad , Chennai , Kolkata , Jaipur , Indore , Thane , Pimpri-Chinchwad , Nashik , Kalyan-Dombivli , Vasai-Virar , Varanasi , Navi Mumbai , Hubli–Dharwad , Tiruchirappalli , Tiruppur , Salem , Mira-Bhayandar , Bhiwandi , Amravati , Noida , Jamshedpur , Bhilai , Cuttack , Firozabad , Kochi , Durgapur , Rourkela , Loni , Siliguri , Ulhasnagar , Sangli-Miraj & Kupwad , Ambattur , Thiruvananthapuram , Davanagere , Kozhikode , Maheshtala , Rajpur Sonarpur , Bokaro , South Dumdum , Gopalpur , Bhatpara , Panihati , Latur , Korba , Kollam , Avadi , Kadapa , Kamarhati , Rampur , Thrissur , Bardhaman , Kulti , Parbhani , Ozhukarai , Bihar Sharif , Panipat , Bally , Aizawl , Dewas , Ichalkaranji , Bathinda , Jalna , Kirari Suleman Nagar , Purnia , Satna , Mau , Sonipat , Farrukhabad , Imphal , Hapur , Arrah , Ambarnath , North Dumdum , New Delhi , Gandhidham , Baranagar , Tiruvottiyur , Thoothukudi , Ramagundam , Silchar , Haridwar , Vijayanagaram , Nagercoil , Sri Ganganagar , Karawal Nagar , Mango , Bulandshahr , Uluberia , Katni , Sambhal , Singrauli , Nadiad , Naihati , Yamunanagar , Bidhannagar , Pallavaram , Munger , Panchkula , Burhanpur , Raurkela Industrial Township , Kharagpur , Hospet , Nangloi Jat , Ongole , Deoghar , Chapra , Haldia , Amroha , Bhind , Bhalswa Jahangir Pur , Madhyamgram , Berhampore , Morbi , Raebareli , Khora, Ghaziabad , Bhusawal , Orai , Phusro , Mehsana , Raiganj , Sirsa , Danapur , Serampore , Sultan Pur Majra , Panvel , Shivpuri , Surendranagar Dudhrej , Unnao , Chinsurah , Alappuzha , Adoni , Katihar , Mahbubnagar , Jorhat , Sasaram , Hajipur , Bongaigaon , Dehri , Madanapalle , Bettiah , Ramgarh , Guntakal , Motihari , Dharmavaram , Medininagar , Phagwara , Hosur , Miryalaguda , Tadipatri , Kishanganj , Jamalpur , Kavali , Buxar , Tezpur , Jehanabad , Gangtok , Assam , Bihar , Chattisgarh , Delhi , Gujarat , Haryana , Himachal Pradesh , Jammu kashmir , Jharkhand , Karnataka , Kerala , Madhya Pradesh , Maharashtra , Odisha , Punjab , Rajasthan , Tamilnadu , Uttar Pradesh , Uttarakhand , west Bengal

WE EXPORT TO FOLLOWING COUTRIES

Switzerland , Afghanistan , Albania , Algeria , Angola , AntiguaandBarbuda , Argentina , Armenia , Aruba , Australia , Austria , Azerbaijan , Bahrain , Bangladesh , Barbados , Belarus , Belgium , Belize , Benin , Bhutan , Bolivia , BosniaandHerzegovina , Botswana , Brazil , Brunei , Bulgaria , BurkinaFaso , Burundi , CaboVerde , Cambodia , Cameroon , Canada , CentralAfricanRepublic , Chad , Chile , China , Colombia , Comoros , Congo , CostaRica , Côted'Ivoire , Croatia , Cyprus , CzechRepublic , Denmark , Djibouti , Dominica , DominicanRepublic , Ecuador , Egypt , ElSalvador , EquatorialGuinea , Eritrea , Eswatini , Ethiopia , Fiji , Finland , France , Gabon , Georgia , Germany , Ghana , Greece , Grenada , Guatemala , Guinea , Guinea-Bissau , Guyana , Haiti , Honduras , HongKong , Hungary , Iceland , Indonesia , Iran , Iraq , Ireland , Israel , Italy , Jamaica , Japan , Jordan , Kazakhstan , Kenya , Kiribati , Kosovo , Kuwait , Kyrgyzstan , Laos , Latvia , Lebanon , Lesotho , Liberia , Libya , Lithuania , Luxembourg , Macau , Madagascar , Malawi , Malaysia , Maldives , Mali , Malta , MarshallIslands , Mauritania , Mauritius , Mexico , Micronesia,FederatedStatesof , Moldova , Mongolia , Montenegro , Morocco , Mozambique , Myanmar , Namibia , Nauru , Netherlands , NewZealand , Nicaragua , Niger , Nigeria , NorthMacedonia , Norway , Oman , Palau , Panama , PapuaNewGuinea , Paraguay , Peru , Philippines , Poland , Portugal , PuertoRico , Qatar , Romania , Russia , Rwanda , SaintKittsandNevis , SaintLucia , SaintVincentandtheGrenadines , Samoa , SanMarino , SãoToméandPríncipe , SaudiArabia , Senegal , Serbia , Seychelles , SierraLeone , Singapore , Slovakia , Slovenia , SolomonIslands , SouthAfrica , SouthKorea , SouthSudan , Spain , SriLanka , Sudan , Suriname , Sweden , Taiwan , Tajikistan , Tanzania , Thailand , TheBahamas , TheGambia , Timor-Leste , Togo , Tonga , TrinidadandTobago , Tunisia , Turkey , Turkmenistan , Tuvalu , Uganda , Ukraine , UnitedArabEmirates , UnitedKingdom , UnitedStates , Uruguay , Uzbekistan , Vanuatu , Venezuela , Vietnam , Yemen , Zambia , Zimbabwe , Estonia , Nepal

Send

Message