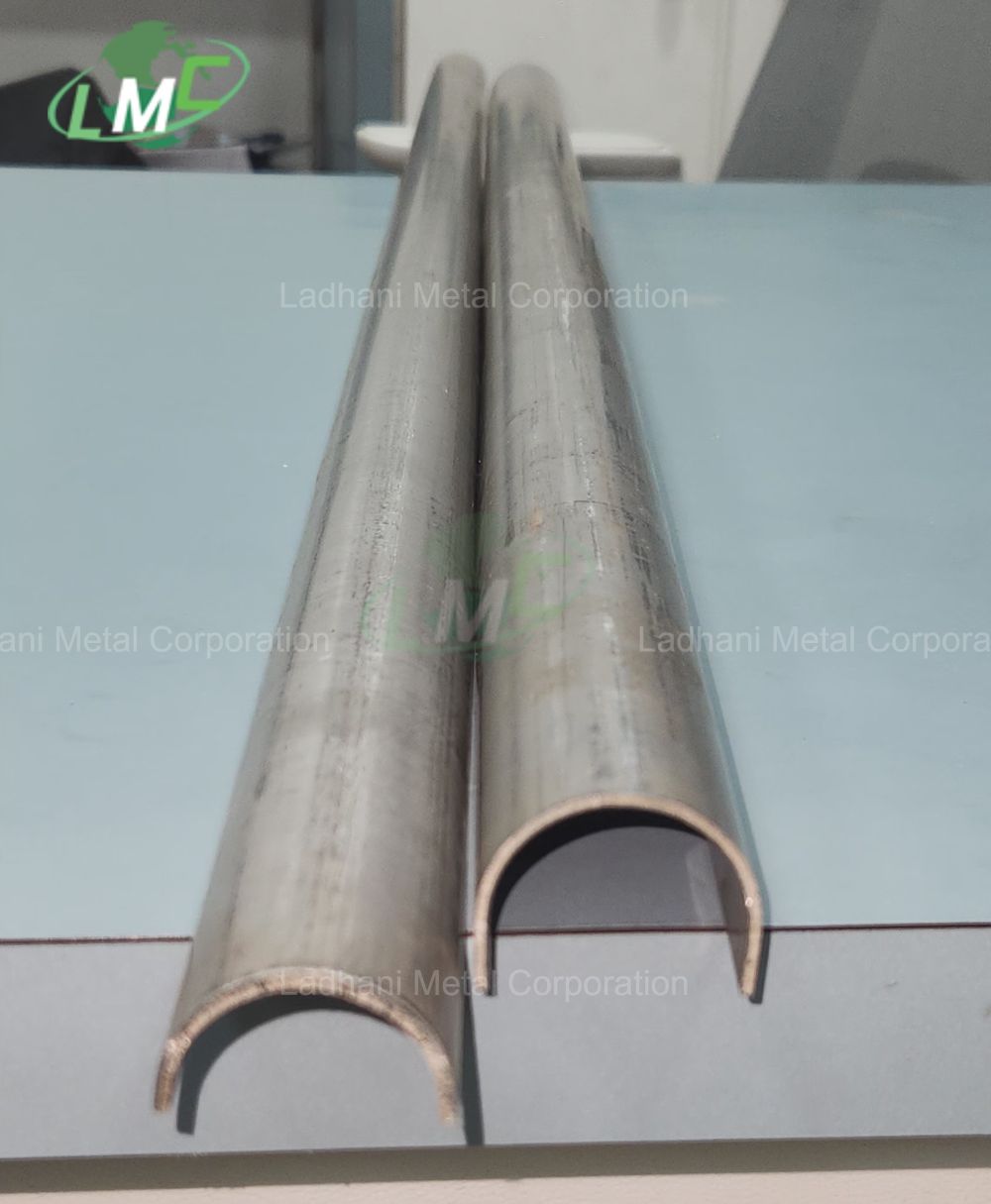

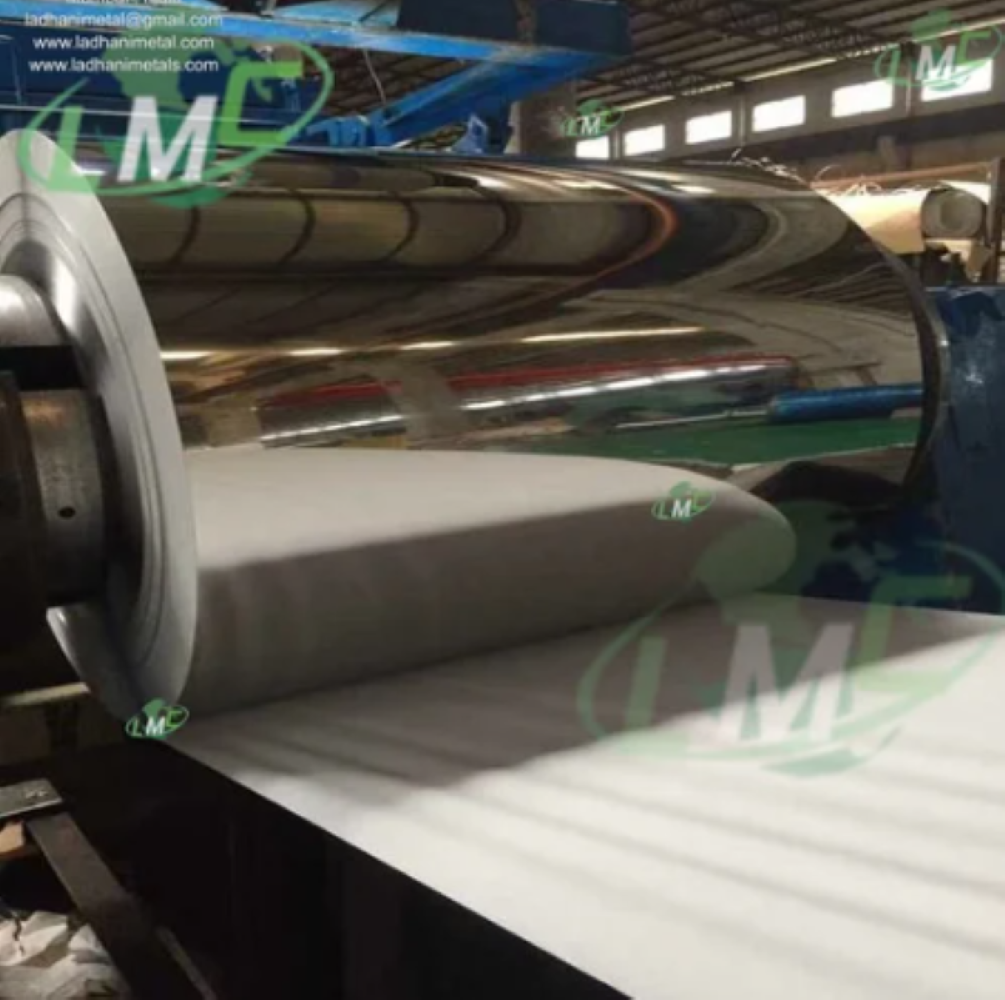

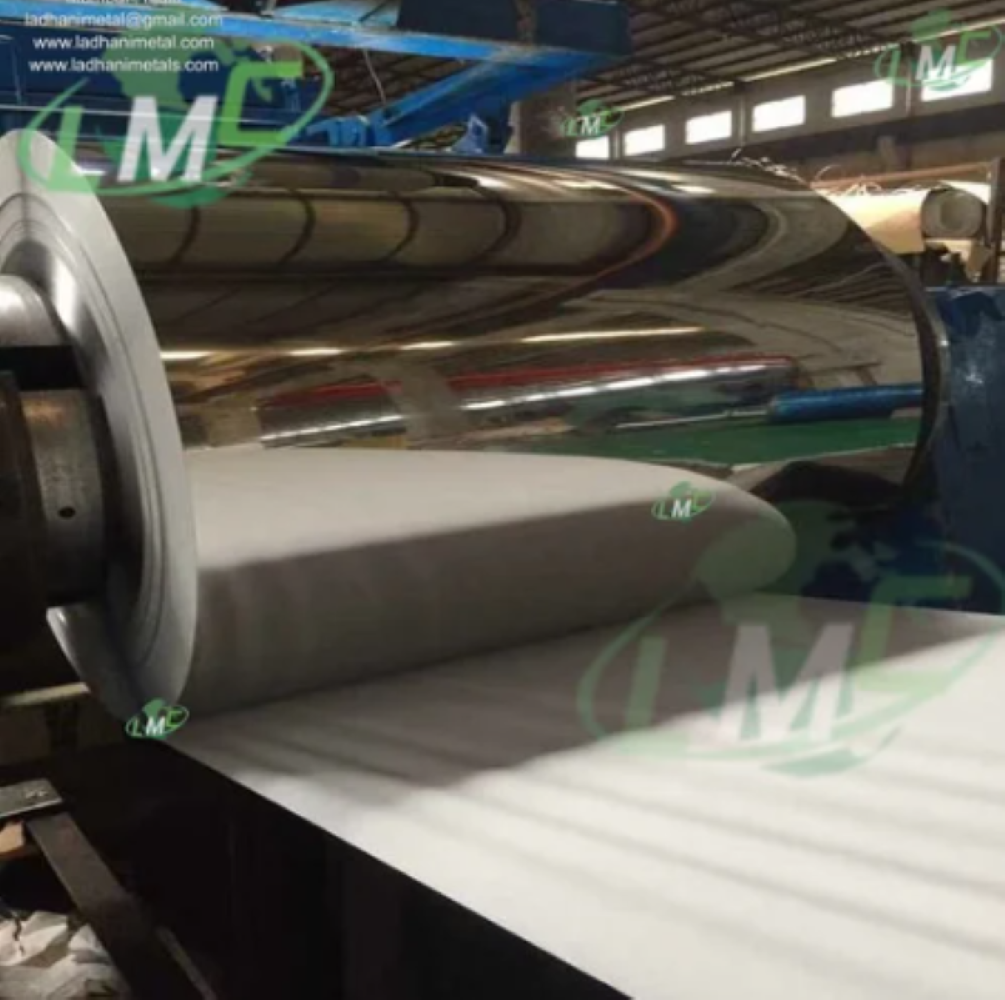

Ladhani Metal Corporation offers Half Round Wedge Wire (WW) Tube Shields designed for protecting boiler tubes against severe erosion, corrosion, and high-velocity flue gas impact in power plants, refineries, petrochemical heaters, waste heat recovery boilers (WHRBs), and heat recovery steam generators (HRSGs). Unlike standard shields, these tube shields feature a wedge wire surface that enhances resistance to abrasive ash particles, improves gas flow dynamics, and reduces localized turbulence, making them ideal for high-erosion environments. Function of WW Tube Shields • Protect boiler tubes from accelerated wear in flue gas zones • Minimize erosion caused by abrasive fly ash and soot blower jets • Improve gas flow distribution by reducing turbulence • Extend tube service life and reduce frequency of replacement Ladhani Metal Corporation manufactures, supplies, and exports Half Round Wedge Wire Tube Shields in standard and customized dimensions to meet diverse industrial and international project requirements. Available Grades • SS 304 / SS 304L • SS 310 / SS 310S • SS 316 / SS 316L • SS 410 / SS 420 / SS 430 • 1Cr13 • 1Cr18Ni9Ti • 1Cr20Ni14Si2 • 1Cr25Ni20Si2 • Cr23Ni13 • Cr25Ni20 Applications: Commonly used in high-dust and erosive sections of boilers including LTSH, economizers, superheaters, and reheaters in thermal power plants, HRSGs, WHRBs, and refinery process heaters. Uses • Protection against flue gas erosion in high-dust zones • Shields superheater, reheater, and economizer tubes from abrasive particles • Reduces damage from soot blower impact • Enhances overall boiler efficiency and tube longevity Features • Wedge wire surface provides superior erosion resistance • Excellent high-temperature oxidation and corrosion resistance • Strong mechanical strength for high-pressure and high-heat environments • Precision-engineered for accurate fit and easy installation Applications • Power generation boilers – Superheater and reheater tube protection • HRSGs and WHRBs – Long-lasting shielding in dust-laden gas streams • Refinery and petrochemical heaters – Reliable under continuous high heat cycles • Industrial steam boilers – Cost-effective tube protection solution Conclusion The Half Round Wedge Wire (WW) Tube Shield by Ladhani Metal Corporation is a robust and advanced solution for boiler tube protection in high-erosion environments. With availability in stainless steel and heat-resistant alloys, these shields deliver durability, precision fit, and long-term reliability, meeting the demanding needs of global energy and process industries.