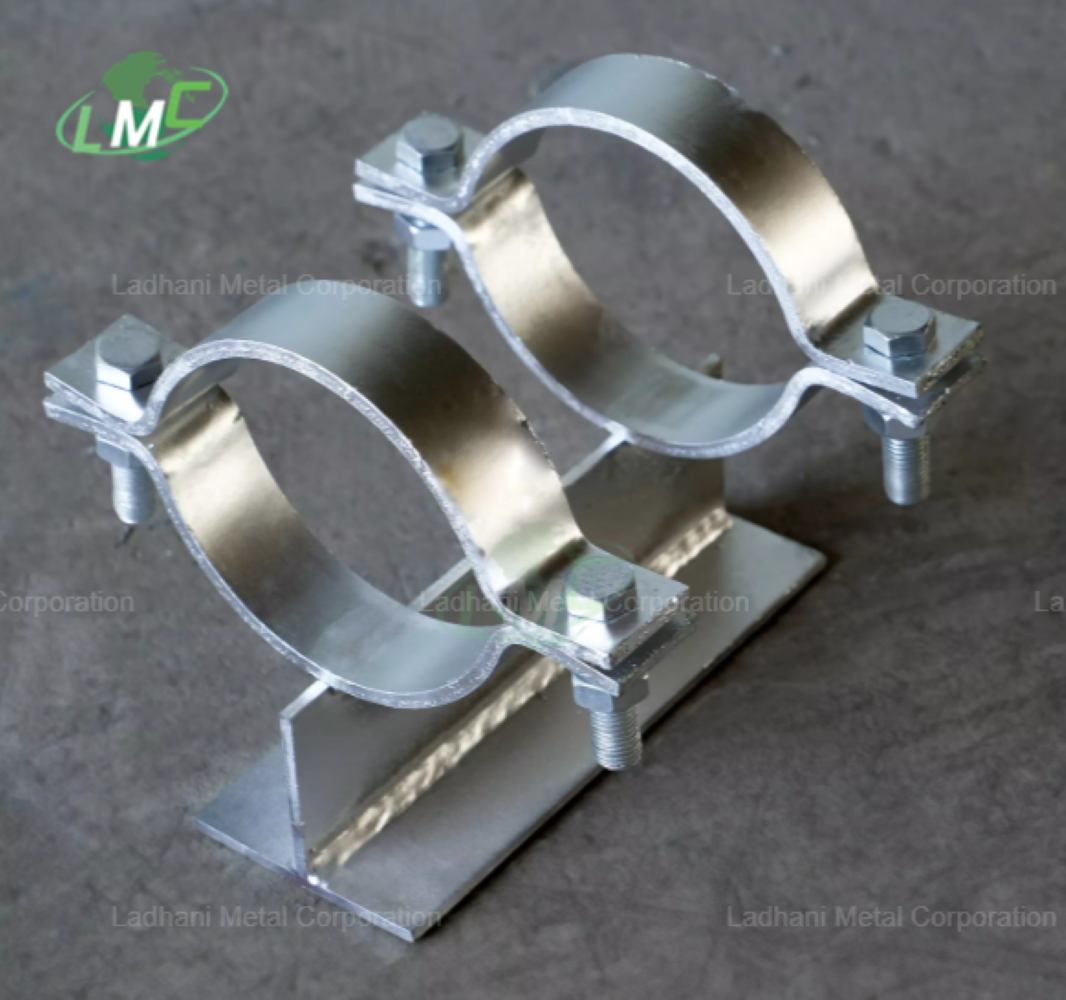

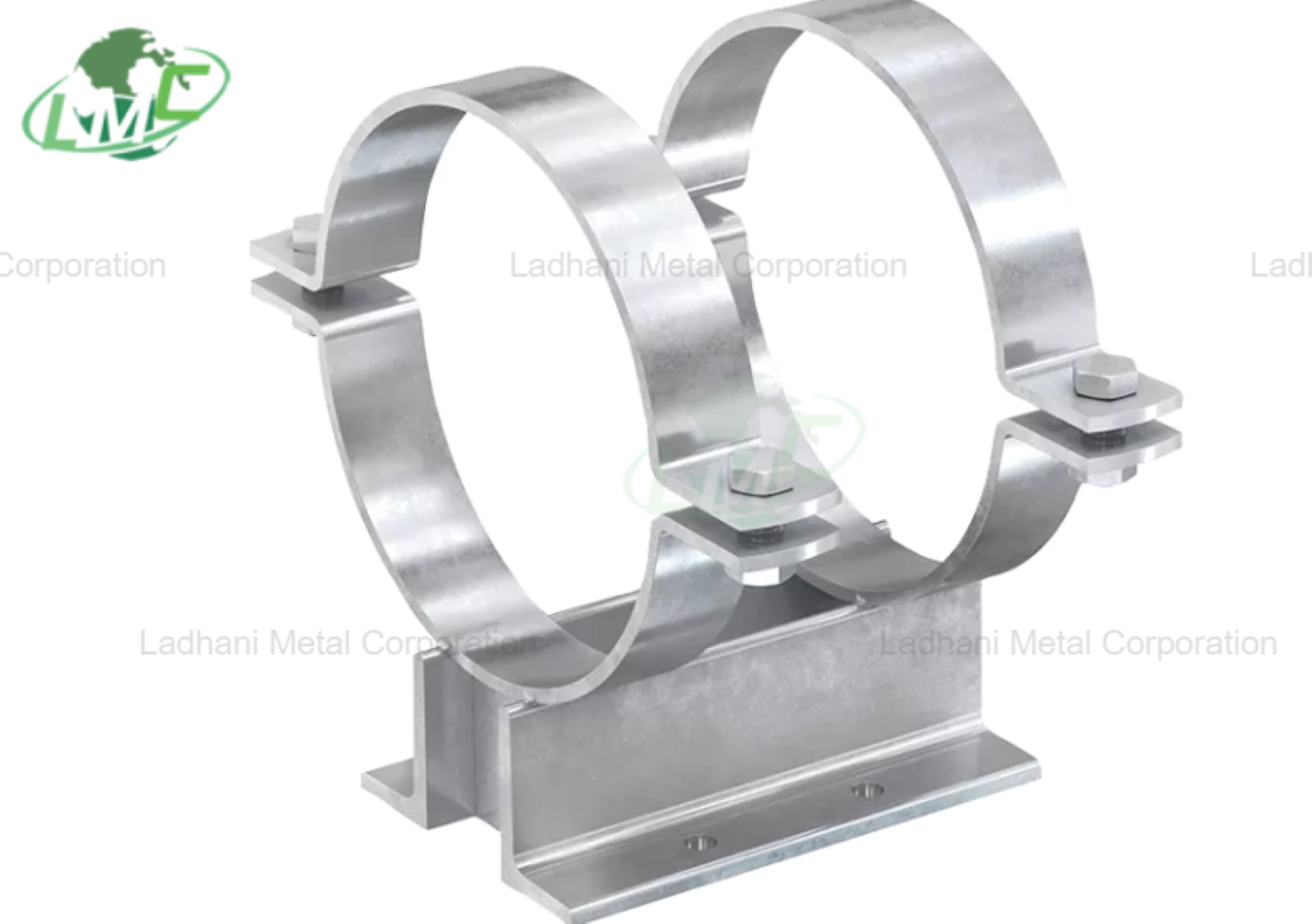

Ladhani Metal Corporation offers SS Adjustable Pipe Shoe Clamps designed to provide flexible and reliable support for pipelines in power plants, refineries, petrochemical units, and process industries. These clamps feature an adjustable design that allows height and clearance modifications, making them ideal for applications where precise alignment and controlled pipe movement are required. Manufactured in high-quality stainless steel, our adjustable pipe shoe clamps ensure strength, durability, and resistance to corrosion in demanding environments. Function of SS Adjustable Pipe Shoe Clamps • Provide stable and adjustable support for process pipelines • Allow fine-tuned height adjustments for accurate pipe alignment • Distribute pipe loads evenly to prevent stress concentration • Compensate for thermal expansion and contraction in pipelines • Prevent direct contact with corrosive or abrasive supporting surfaces Ladhani Metal Corporation manufactures, supplies, and exports SS Adjustable Pipe Shoe Clamps in different sizes and finishes, meeting both domestic and international project requirements. Available Grades • SS 304 • SS 304L • SS 316 • SS 316L Applications Widely used in industries where precise pipe alignment, adjustability, and corrosion resistance are critical. • Refineries and petrochemical plants • Fertilizer and chemical processing units • Oil and gas transmission pipelines • Power generation boilers and piping systems • Marine and offshore engineering Uses • Provides reliable adjustable support for process pipelines • Reduces stress, vibration, and wear on piping systems • Ensures proper thermal movement and expansion clearance • Helps maintain pipeline insulation integrity • Suitable for heavy-duty and high-temperature applications Features • Adjustable design for precise pipeline alignment • High load-bearing capacity and robust construction • Resistance to corrosion and oxidation in harsh environments • Long service life with minimal maintenance requirements • Manufactured in SS 304, 304L, 316, and 316L grades Conclusion The SS Adjustable Pipe Shoe Clamp from Ladhani Metal Corporation delivers strength, flexibility, and long-term durability for pipeline support systems. Manufactured in SS 304, SS 304L, SS 316, and SS 316L grades, these clamps provide reliable service in industries where adjustability, corrosion resistance, and accurate fit are essential. For inquiries or project requirements, contact Ladhani Metal Corporation #Mumbai #Delhi #Bangalore #Hyderabad #Chennai #Kolkata #Pune #Ahmedabad #Surat #Vadodara #Rajkot #Nagpur #Indore #Bhopal #Jaipur #Lucknow #Kanpur #Patna #Ranchi #Jamshedpur #Bhubaneswar #Raipur #Visakhapatnam #Vijayawada #Coimbatore #Madurai #Kochi #Trivandrum #Tiruchirappalli #Mangalore #Mysore #Noida #Gurgaon #Faridabad #Ghaziabad #Ludhiana #Amritsar #Chandigarh #Jalandhar #Agra #Varanasi #Meerut #Aurangabad #Nashik #Solapur #Gwalior #Allahabad #Guwahati #Shillong #PipeShoeClamp #StainlessSteelPipeShoeClamp #SSPipeShoeClamp #PipeShoeClampManufacturer #PipeShoeClampSupplier #PipeShoeClampExporter #PipeShoeClampIndia #IndustrialPipeShoeClamp #HeavyDutyPipeShoeClamp #CustomPipeShoeClamp #HighQualityPipeShoeClamp #304PipeShoeClamp #316PipeShoeClamp #304LPipeShoeClamp #316LPipeShoeClamp #PipeShoeClampFittings #PipeShoeClampSupport #SS304PipeShoeClamp #SS316PipeShoeClamp #SS316LPipeShoeClamp #SS304LPipeShoeClamp #PipeShoeClampDesign #PipeShoeClampApplication #PipeShoeClampForBoilers #PipeShoeClampForRefinery #PipeShoeClampForPetrochemical #PipeShoeClampForPowerPlant #PipeShoeClampForOilAndGas #PipeShoeClampForChemicalPlant #PipeShoeClampSolutions #PipeShoeClampProducts #PipeShoeClampFabrication #PipeShoeClampInstallation #PipeShoeClampSupportSystem #PipeShoeClampAssembly #PipeShoeClampHardware #PipeShoeClampTechnology #DurablePipeShoeClamp #ReliablePipeShoeClamp #PipeShoeClampStockist #PipeShoeClampWholesale #PipeShoeClampTrading #PipeShoeClampDistribution #PipeShoeClampExports #PipeShoeClampWorldwide #PipeShoeClampIndustry #PipeShoeClampMarket #PipeShoeClampOnline #PipeShoeClampComponents #PipeShoeClampSystems