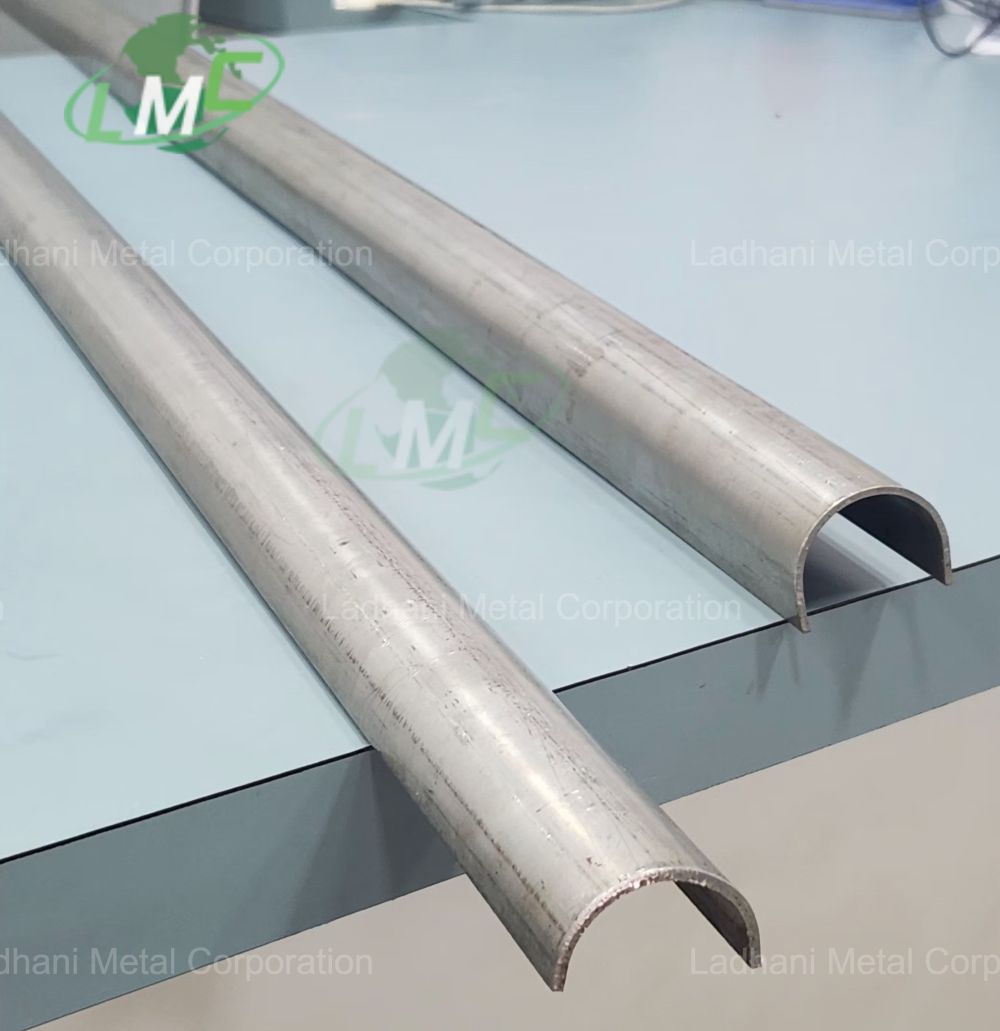

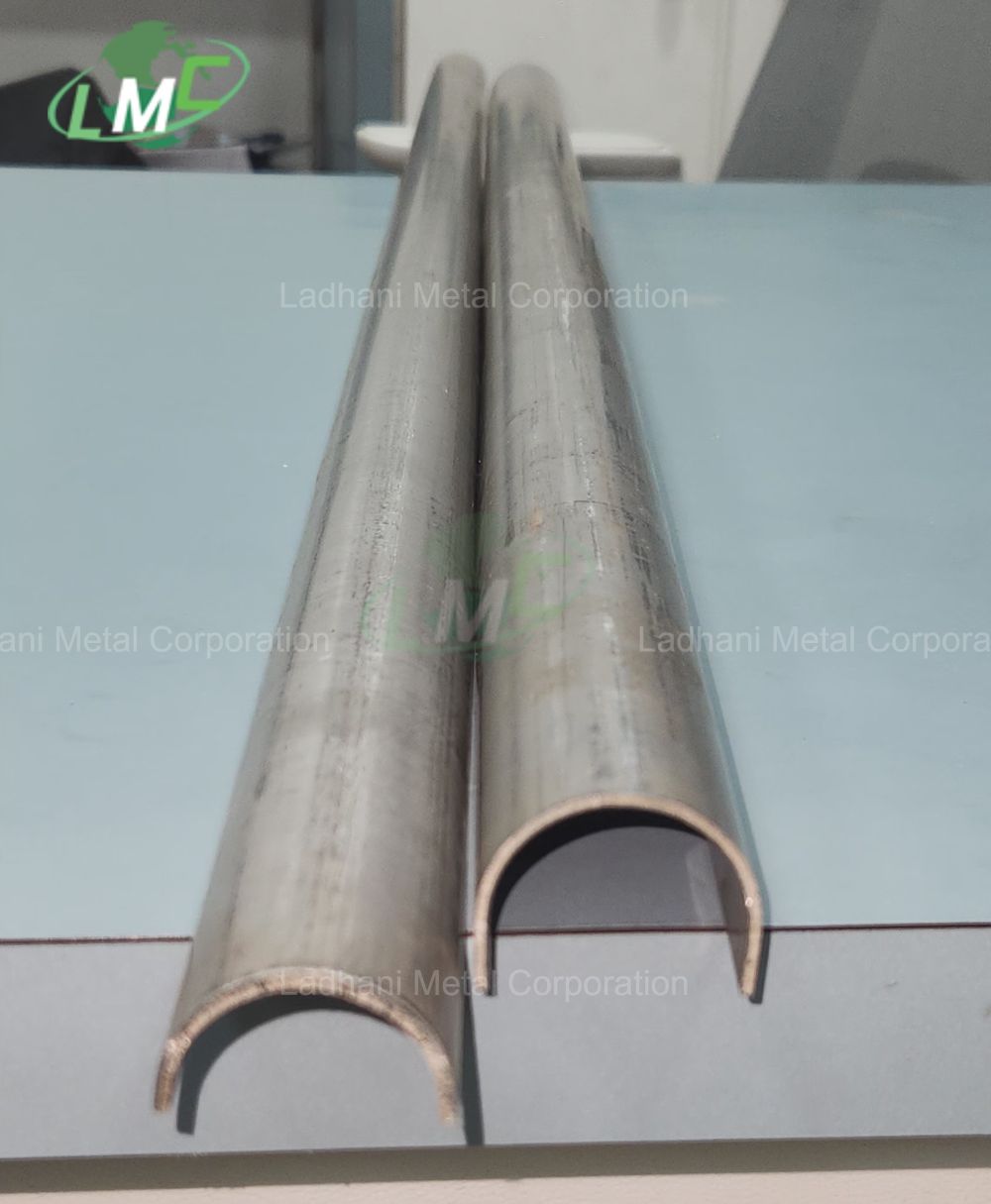

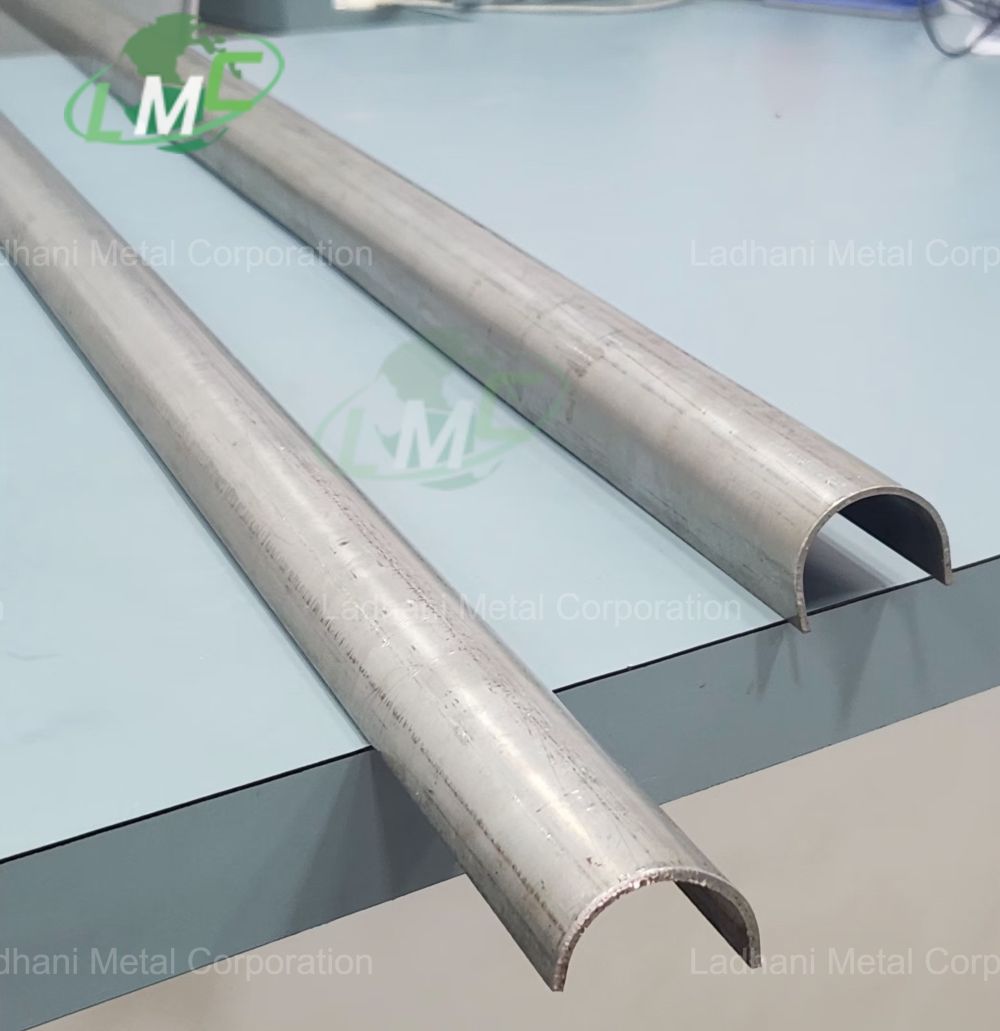

Ladhani Metal Corporation offers SS 420 Boiler Half Round Tube Shields designed to protect straight boiler and heat exchanger tubes from erosion, scaling, and high-temperature wear. SS 420 is particularly effective in dry flue gas conditions and abrasive particle exposure. The shields are precision-formed into a half-round profile to match the curvature of standard boiler tubes, ensuring a secure fit and consistent coverage. This design offers a strong protective barrier against soot blower impact, fly ash abrasion, and surface scaling, thereby extending tube service life and reducing maintenance costs. Ladhani Metal Corporation manufactures, supplies, and exports SS 420 Boiler Half Round Tube Shields in a wide range of lengths, diameters, and thicknesses to meet specific requirements for domestic and international applications. SS 420 Grade Chemical Composition – Martensitic Stainless Steel • Carbon (C): 0.15 – 0.40% • Manganese (Mn): ≤ 1.00% • Phosphorus (P): ≤ 0.040% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 12.0 – 14.0% • Nickel (Ni): ≤ 0.75% • Iron (Fe): Balance Applications: Suitable for high-temperature and abrasive service environments such as power plant boilers, waste heat recovery systems, and process heaters. Uses • Shields straight boiler tubes in utility and industrial boilers • Protection from soot blower erosion and ash particle wear • Suitable for dry, high-temperature flue gas areas • Used in furnaces and process heaters with abrasive gas streams • Effective in extending tube life in cost-sensitive operations Features • High strength and hardness – Withstands mechanical impact and wear • Good oxidation resistance – Performs well in dry heat environments • Cost-effective – Offers durability at a competitive material cost • Precision fit – Half-round profile ensures full contact and coverage • Simple installation – Can be clamped, banded, or tack welded • Export ready – Manufactured to meet global dimensional and quality standards Applications • Thermal power plants – For protection of superheater and economizer tubes • Petrochemical and refinery boilers – Guards against scaling and erosion • Waste heat boilers – Effective against particulate-laden flue gases • Cement industry – Shields tubes from abrasive kiln dust exposure Conclusion The SS 420 Boiler Half Round Tube Shield from Ladhani Metal Corporation offers durable and wear-resistant protection for boiler tubes in high-temperature, abrasive service environments. Combining strength, hardness, and oxidation resistance, these shields are an effective solution for extending tube life and minimizing downtime. Available in custom dimensions and export-grade quality, they serve industrial boiler systems worldwide. For technical assistance, sizing options, or global supply inquiries, contact Ladhani Metal Corporation. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Salem #Erode #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Hassan #Cuttack #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Gaya #Muzaffarpur#halftubeshield #utypehalftubeshield #tubeshieldexporter #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield

Send Message