Product Name: Anodic Titanium Jigs

Material: Gr1, Gr2

Size: Customized

Surface: Polished

Anodic Titanium Jigs:

Hanger/jig/rack, in electroplating and related operations, a frame for suspending a workpiece and directing an electric current to the workpiece.

Hangers come in many forms, from general hangers for several common parts to hangers for large quantities of parts. For plating parts with complex geometry, some should be equipped with auxiliary anode, auxiliary cathode or shielding plate

The basic principle of hanger design is: enough mechanical strength and good electrical conductivity, light weight, easy to unload, parts and hanger firmly contact.

The titanium hanger has sufficient mechanical strength and good electrical conductivity

Product Name:Anodic Titanium Jigs

Material: Gr1, Gr2

Application: Electroplating, anodizing etc.

Size: Customized

Surface: Polished

Characteristics:

1. High density, heavy, high hardness and toughness;

2. Corrosion resistance in anodic treatment;

3. No insulation layer will be formed after anodic treatment.

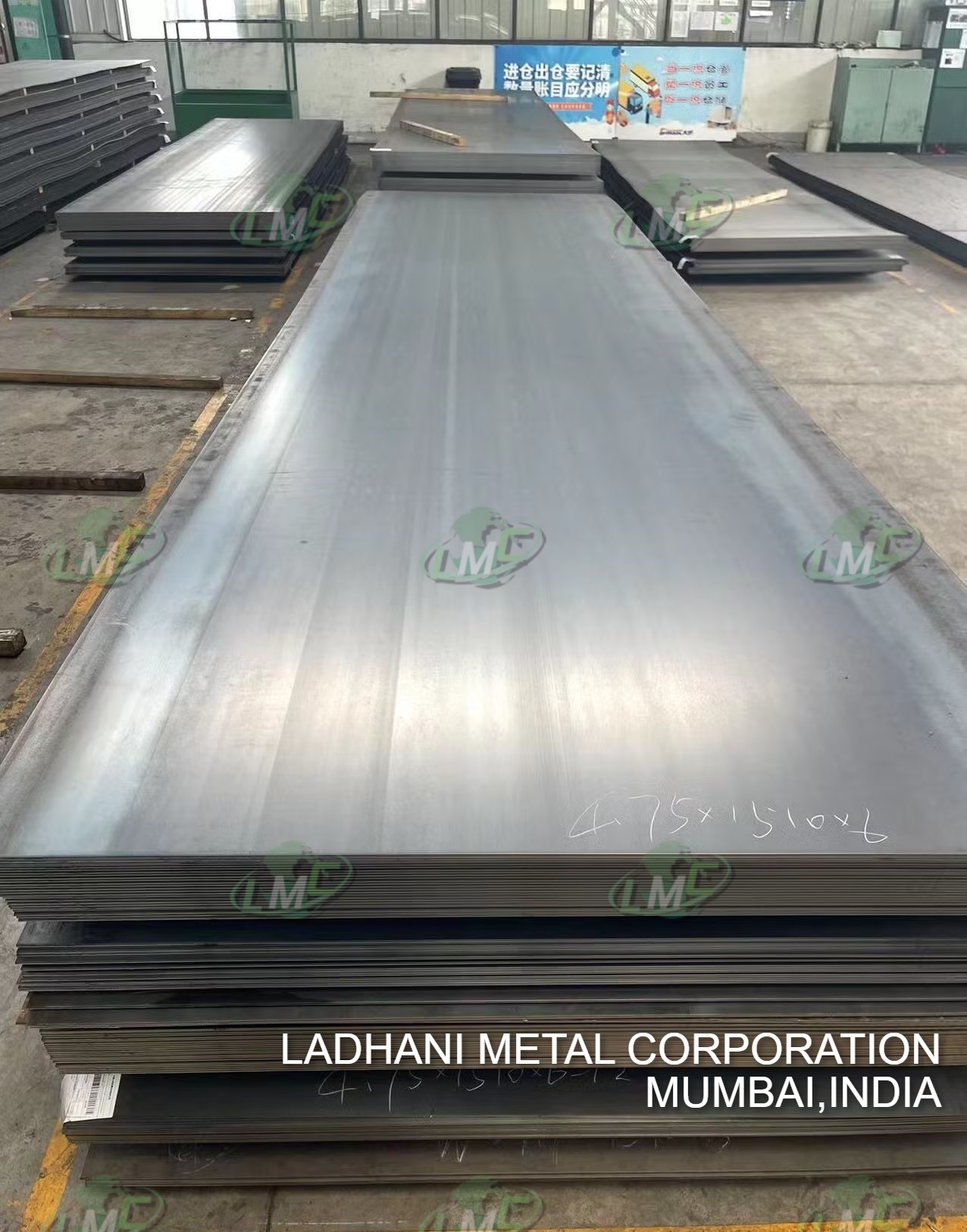

LADHANI METAL CORPORATION, MUMBAI, INDIA

Company Information

Ladhani Metal Corporation.

We are committed to integrate engineering steel resources in India and serve the global engineering steel market. Our company has more than 32 years of experience in steel researching, production, managing and sales.

In the aspect of resources and information, we have established cooperative and stronger relationship with nearly hundred enterprises, either state-owned or private owned in India.

What’s more, we have built long, deep and close business relationship with dozens of steel company, Sharing and holding equities with several steel enterprises. Because of the close cooperation with steel companies and our pioneering spirit, which can ensure us stay at the top competition, and ensure our customers get what they really want!

FOR MORE DETAIL CONTACT US AT :-

ladhanimetal@gmail.com

ladhanimetals@gmail.com

www.ladhanimetal.in

www.ladhanimetal.com

LADHANI METAL CORPORATION, MUMABAI, INDIA,

AVAILABLE AT FOLLOWING LOCATION:-

Adilabad, Agartala, Agra, Ahmedabad, Ahmednagar, Ajmer, Akola , Aligarh , Alipore , Allahabad , Alleppey , Almora , Alwar , Alwaye , Amalapuram , Amaravati , Ambala , Amreli , Amritsar , Anakapalle , Anand , Anantapur , Andhra Pradesh , Anna Road , Arakkonam , Arunachal Pradesh , Asansol , Aska , Assam , Aurangabad , Azamgarh , Bagalkot , Bahraich , Balaghat , Balangir , Balasore , Ballia , Banasanktha , Banda , Bangalore , Bankura , Barabanki , Barabazaar , Baramulla , Barasat , Bardoli , Bareilly , Barmer , Bastar , Basti , Beawar , Beed , Begusarai , Belgaum , Bellary , Berhampur , Bhadrak , Bhagalpur , Bharatpur , Bharuch , Bhatinda , Bhavnagar , Bhilwara , Bhimavaram , Bhiwani , Bhojpur , Bhopal , Bhubaneswar , Bhusaval , Bidar , Bihar , Bijapur , Bijnor , Bikaner , Bilaspur , Birbhum , Budaun , Bulandshahar , Buldana , Burdwan , Cachar , Calcutta , Calicut , Cannanore , Chamba , Chamoli , Chandigarh , Chandrapur , Changanacherry , Channapatna , Chattisgarh , Chengalpattu , Chennai , Chhatarpur , Chhindwara , Chikmagalur , Chikodi , Chitradurga , Chittoor , Chittorgarh , Churu , Coimbatore , Contai , Cooch Behar , Cuddalore , Cuddapah , Cuttack , Darbhanga , Darjeeling , Darrang , Dehra Gopipur , Dehradun , Delhi , Delhi , Deoria , Dhanbad , Dharamsala , Dharmanagar , Dharmapuri , Dharwad , Dhenkanal , Dholpur , Dhule , Dibrugarh , Dinajpur , Dindigul , divisionname , Dungarpur , Durg , Eluru , Ernakulam , Erode , Etah , Etawah , Faizabad , Faridabad , Faridkot , Fatehgarh , Fatehpur , Ferozpur , Gadag , Gandhinagar , Gaya , Ghaziabad , Ghazipur , Giridih , Goa , Goalpara , Gokak , Gonda , Gondal , Gorakhpur , Gudivada , Gudur , Gujarat , Gulbarga , Guna , Guntur , Gurdaspur , Gurgaon , Guwahati , Gwalior , Hamirpur , Hanamkonda , Hardoi , Haryana , Hassan , Haveri , Hazaribagh , Himachal Pradesh , Hindupur , Hissar , Hooghly , Hoshangabad , Hoshiarpur , Howrah , Hyderabad , Idukki , Indore , Irinjalakuda , Jabalpur , Jaipur , Jalandhar , Jalgaon , Jalpaiguri , Jammu , Jammu kashmir , Jamnagar , Jaunpur , Jhansi , Jharkhand , Jhunjhunu , Jodhpur , Junagadh , Kakinada , Kalahandi , Kanchipuram , Kanniyakumari , Kanpur , Kapurthala , Karaikudi , Karimnagar , Karnal , Karnataka , Karur , Karwar , Kasaragod , Keonjhar , Kerala , Khammam , Khandwa , Kheda , Kheri , Kodagu , Kolar , Kolhapur , Kolkata , Koraput , Kota , Kottayam , Kovilpatti , Krishnagiri , Kumbakonam , Kurnool , Kurukshetra , Kutch , Lakshadweep , Leh , Lucknow , Ludhiana , Machilipatnam , Madhubani , Madhya Pradesh , Madurai , Mahabubnagar , Maharashtra , Mahesana , Mainpuri , Malda , Malegaon , Mandi , Mandsaur , Mandya , Mangalore , Manipur , Manjeri , Mathura , Mavelikara , Mayiladuthurai , Mayurbhanj , Medak , Meerut , Meghalaya , Midnapore , Mirzapur , Mizoram , Monghyr , Moradabad , Morena , Mumbai , Murshidabad , Muzaffarnagar , Muzaffarpur , Mysore , Nadia , Nagaland , Nagaon , Nagapattinam , Nagaur , Nagpur , Nainital , Nalanda , Nalbari , Nalgonda , Namakkal , Nanded , Nandyal , Nanjangud , Narasaraopet , Nasik , Navsari , Nawadha , Nellore , New Delhi , New Mumbai , Nilgiris , Nizamabad , North Eastern , Odisha , Osmanabad , Ottapalam , Palamau , Palghat , Pali , Panchmahals , Pandharpur , Parvathipuram , Patan , Pathanamthitta , Patiala , Patna , Pattukottai , Pauri , Peddapalli , Pharbhani , Phulbani , Pithoragarh , Pollachi , Pondicherry , Porbandar , Prakasam , Pratapgarh , Proddatur , Pudukkottai , Pune , Punjab , Puri , Purnea , Purulia , Puttur , Quilon , Rae Bareilly , Raichur , Raigad , Raigarh , Raipur , Rajahmundry , Rajasthan , Rajkot , Rajouri , Ramanathapuram , Rampur Bushahr , Ranchi , Ratlam , Ratnagiri , Rewa , Rohtak , Rohtas , Sabarkantha , Sagar , Saharanpur , Saharsa , Salem , Samastipur , Sambalpur , Sangareddy , Sangli , Sangrur , Santhal Parganas , Saran , Satara , Sawaimadhopur , Secunderabad , Sehore , Shahdol , Shahjahanpur , Shimla , Shimoga , Shrirampur , Sibsagar , Sikar , Sikkim , Sindhudurg , Singhbhum , Sirohi , Sirsi , Sitamarhi , Sitapur , Sivaganga , Siwan , Solan , Solapur , Sonepat , Sriganganagar , Srikakulam , Srinagar , Srirangam , Sultanpur , Sundargarh , Surat , Surendranagar , Suryapet , Tadepalligudem , Tambaram , Tamilnadu , Tamluk , Tehri , Tenali , Thalassery , Thane , Thanjavur , Theni , Tinsukia , Tiruchirapalli , Tirunelveli , Tirupati , Tirupattur , Tirupur , Tirur , Tiruvalla , Tiruvannamalai , Tonk , Trichur , Trivandrum , Tumkur , Tuticorin , Udaipur , Udhampur , Udupi , Ujjain , Una , Uttar Pradesh , Uttarakhand , Vadakara , Vadodara , Vaishali , Valsad , Varanasi , Vellore , Vidisha , Vijayawada , Virudhunagar , Visakhapatnam , Vizianagaram , Vriddhachalam , Wanaparthy , Warangal , Wardha , West Bengal , Yeotmal , Bangalore , Hyderabad , Chennai , Kolkata , Jaipur , Indore , Thane , Pimpri-Chinchwad , Nashik , Kalyan-Dombivli , Vasai-Virar , Varanasi , Navi Mumbai , Hubli–Dharwad , Tiruchirappalli , Tiruppur , Salem , Mira-Bhayandar , Bhiwandi , Amravati , Noida , Jamshedpur , Bhilai , Cuttack , Firozabad , Kochi , Durgapur , Rourkela , Loni , Siliguri , Ulhasnagar , Sangli-Miraj & Kupwad , Ambattur , Thiruvananthapuram , Davanagere , Kozhikode , Maheshtala , Rajpur Sonarpur , Bokaro , South Dumdum , Gopalpur , Bhatpara , Panihati , Latur , Korba , Kollam , Avadi , Kadapa , Kamarhati , Rampur , Thrissur , Bardhaman , Kulti , Parbhani , Ozhukarai , Bihar Sharif , Panipat , Bally , Aizawl , Dewas , Ichalkaranji , Bathinda , Jalna , Kirari Suleman Nagar , Purnia , Satna , Mau , Sonipat , Farrukhabad , Imphal , Hapur , Arrah , Ambarnath , North Dumdum , New Delhi , Gandhidham , Baranagar , Tiruvottiyur , Thoothukudi , Ramagundam , Silchar , Haridwar , Vijayanagaram , Nagercoil , Sri Ganganagar , Karawal Nagar , Mango , Bulandshahr , Uluberia , Katni , Sambhal , Singrauli , Nadiad , Naihati , Yamunanagar , Bidhannagar , Pallavaram , Munger , Panchkula , Burhanpur , Raurkela Industrial Township , Kharagpur , Hospet , Nangloi Jat , Ongole , Deoghar , Chapra , Haldia , Amroha , Bhind , Bhalswa Jahangir Pur , Madhyamgram , Berhampore , Morbi , Raebareli , Khora, Ghaziabad , Bhusawal , Orai , Phusro , Mehsana , Raiganj , Sirsa , Danapur , Serampore , Sultan Pur Majra , Panvel , Shivpuri , Surendranagar Dudhrej , Unnao , Chinsurah , Alappuzha , Adoni , Katihar , Mahbubnagar , Jorhat , Sasaram , Hajipur , Bongaigaon , Dehri , Madanapalle , Bettiah , Ramgarh , Guntakal , Motihari , Dharmavaram , Medininagar , Phagwara , Hosur , Miryalaguda , Tadipatri , Kishanganj , Jamalpur , Kavali , Buxar , Tezpur , Jehanabad , Gangtok , Assam , Bihar , Chattisgarh , Delhi , Gujarat , Haryana , Himachal Pradesh , Jammu kashmir , Jharkhand , Karnataka , Kerala , Madhya Pradesh , Maharashtra , Odisha , Punjab , Rajasthan , Tamilnadu , Uttar Pradesh , Uttarakhand , west Bengal

WE EXPORT TO FOLLOWING COUTRIES

Switzerland , Afghanistan , Albania , Algeria , Angola , AntiguaandBarbuda , Argentina , Armenia , Aruba , Australia , Austria , Azerbaijan , Bahrain , Bangladesh , Barbados , Belarus , Belgium , Belize , Benin , Bhutan , Bolivia , BosniaandHerzegovina , Botswana , Brazil , Brunei , Bulgaria , BurkinaFaso , Burundi , CaboVerde , Cambodia , Cameroon , Canada , CentralAfricanRepublic , Chad , Chile , China , Colombia , Comoros , Congo , CostaRica , Côted'Ivoire , Croatia , Cyprus , CzechRepublic , Denmark , Djibouti , Dominica , DominicanRepublic , Ecuador , Egypt , ElSalvador , EquatorialGuinea , Eritrea , Eswatini , Ethiopia , Fiji , Finland , France , Gabon , Georgia , Germany , Ghana , Greece , Grenada , Guatemala , Guinea , Guinea-Bissau , Guyana , Haiti , Honduras , HongKong , Hungary , Iceland , Indonesia , Iran , Iraq , Ireland , Israel , Italy , Jamaica , Japan , Jordan , Kazakhstan , Kenya , Kiribati , Kosovo , Kuwait , Kyrgyzstan , Laos , Latvia , Lebanon , Lesotho , Liberia , Libya , Lithuania , Luxembourg , Macau , Madagascar , Malawi , Malaysia , Maldives , Mali , Malta , MarshallIslands , Mauritania , Mauritius , Mexico , Micronesia,FederatedStatesof , Moldova , Mongolia , Montenegro , Morocco , Mozambique , Myanmar , Namibia , Nauru , Netherlands , NewZealand , Nicaragua , Niger , Nigeria , NorthMacedonia , Norway , Oman , Palau , Panama , PapuaNewGuinea , Paraguay , Peru , Philippines , Poland , Portugal , PuertoRico , Qatar , Romania , Russia , Rwanda , SaintKittsandNevis , SaintLucia , SaintVincentandtheGrenadines , Samoa , SanMarino , SãoToméandPríncipe , SaudiArabia , Senegal , Serbia , Seychelles , SierraLeone , Singapore , Slovakia , Slovenia , SolomonIslands , SouthAfrica , SouthKorea , SouthSudan , Spain , SriLanka , Sudan , Suriname , Sweden , Taiwan , Tajikistan , Tanzania , Thailand , TheBahamas , TheGambia , Timor-Leste , Togo , Tonga , TrinidadandTobago , Tunisia , Turkey , Turkmenistan , Tuvalu , Uganda , Ukraine , UnitedArabEmirates , UnitedKingdom , UnitedStates , Uruguay , Uzbekistan , Vanuatu , Venezuela , Vietnam , Yemen , Zambia , Zimbabwe , Estonia , Nepal

Price: 0 |

Payment Type: |

Available: False |

COD Available: False |

KYC Status: FAILED

Send Message