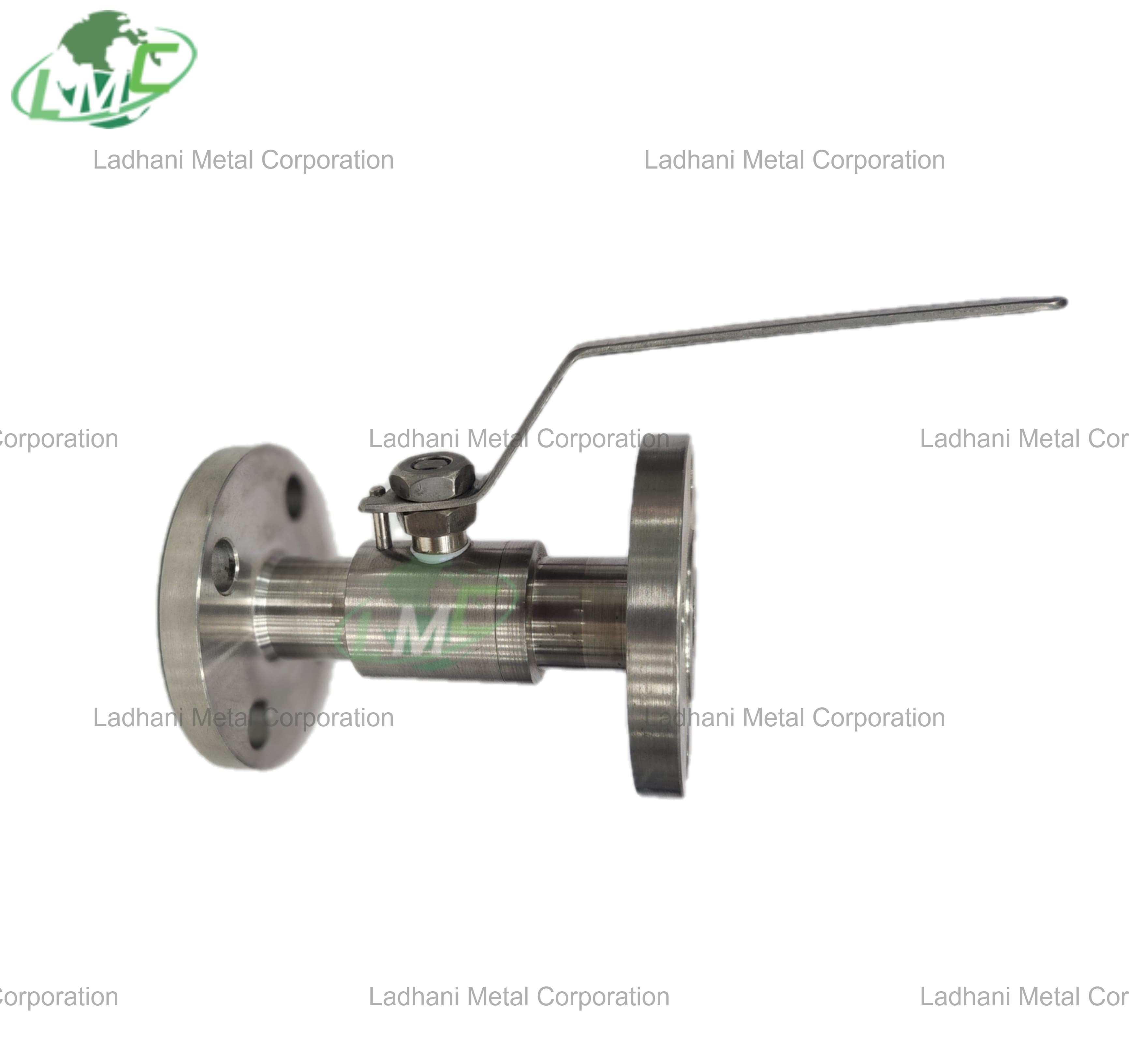

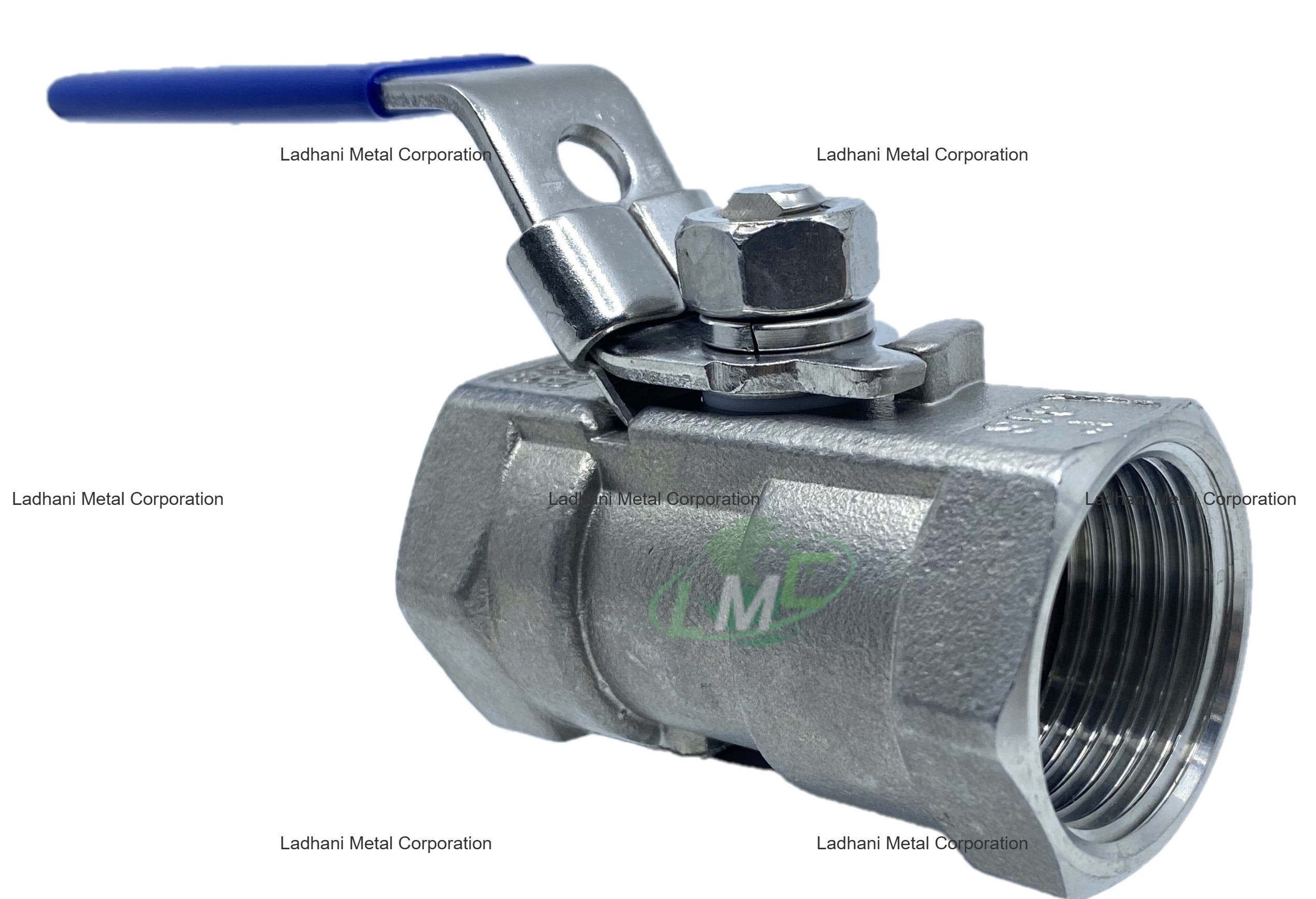

DIN 2576 Monel Flanges PN 10 are high-integrity, slip-on flanges manufactured from corrosion-resistant nickel-copper alloys, specifically designed for demanding low to medium-pressure applications. Compliant with the DIN 2576 standard, these flanges provide exceptional resistance to seawater, acids, alkalis, and corrosive chemicals, making them ideal for highly corrosive industrial environments. The slip-on design allows the flange to be positioned over the pipe and welded in place, ensuring precise alignment and long-term mechanical stability. Ladhani Metal Corporation is a trusted manufacturer and international supplier of Monel flanges, producing components that meet rigorous dimensional, metallurgical, and quality standards. DIN 2576 Monel flanges are widely used in marine, chemical, and oil and gas industries, where material durability and corrosion resistance are critical. Pressure Rating: • PN 10 (10 bar / 145 psi): Designed for systems requiring stable operation under moderate pressures in fluid and gas transport environments. Flange Types: • Slip-On Flanges Facilitate easy assembly by slipping over the pipe and welding on both sides to ensure a leak-proof and secure joint. • Flat Face (FF) Flanges Designed for use with flat gaskets and mating surfaces, offering even pressure distribution and sealing performance, particularly with brittle or non-metallic materials. Monel Grades and Composition: Monel 400 (UNS N04400) Composition: • Nickel (Ni): ≥ 63.0% • Copper (Cu): 28.0 – 34.0% • Iron (Fe), Manganese (Mn), Silicon (Si), Carbon (C): Trace amounts Applications: Monel 400 is well-known for its outstanding resistance to seawater, hydrofluoric acid, sulfuric acid, and alkalis. It is widely used in marine engineering, chemical processing, and heat exchangers. Monel K500 (UNS N05500) Composition: • Nickel (Ni): ≥ 63.0% • Copper (Cu): ~30.0% • Aluminum (Al): 2.3 – 3.15% • Titanium (Ti): 0.35 – 0.85% Applications: Monel K500 offers the same corrosion resistance as Monel 400 but with significantly higher strength and hardness due to age-hardening. It is ideal for high-stress applications such as pump shafts, valve components, and marine fasteners. Applications of DIN 2576 Monel Flanges: • Marine and Offshore Engineering Ideal for seawater exposure, ballast systems, and structural applications in shipbuilding and offshore platforms. • Chemical and Petrochemical Processing Used in piping systems exposed to strong acids, caustics, and other corrosive agents. • Oil and Gas Industry Suitable for sour gas (H₂S) environments, offshore drilling equipment, and refining systems. • Heat Exchangers and Condensers Monel's thermal conductivity and corrosion resistance make it suitable for tube sheets and connecting flanges. • Power Generation Applied in cooling systems, boiler feedwater lines, and other aggressive service environments. • Aerospace and Defense Used in fuel and hydraulic systems where resistance to corrosion and stress cracking is required. Key Features: • Manufactured according to DIN 2576 specification • PN 10 pressure rating for low to medium-pressure fluid systems • Exceptional resistance to seawater, acids, alkalis, and chlorides • Available in Monel 400 and Monel K500 grades • Slip-on design enables easy installation and welding • Flat face versions for compatibility with flat gaskets and brittle materials • Excellent mechanical properties and corrosion resistance • Custom dimensions, finishes, and face types available upon request Conclusion: DIN 2576 Monel Flanges PN 10 from Ladhani Metal Corporation deliver high corrosion resistance and mechanical strength for aggressive environments where conventional materials fail. With availability in Monel 400 and K500 grades, these flanges are suitable for marine, oil & gas, and chemical applications. For technical support, project consultation, or custom orders, contact Ladhani Metal Corporation today.