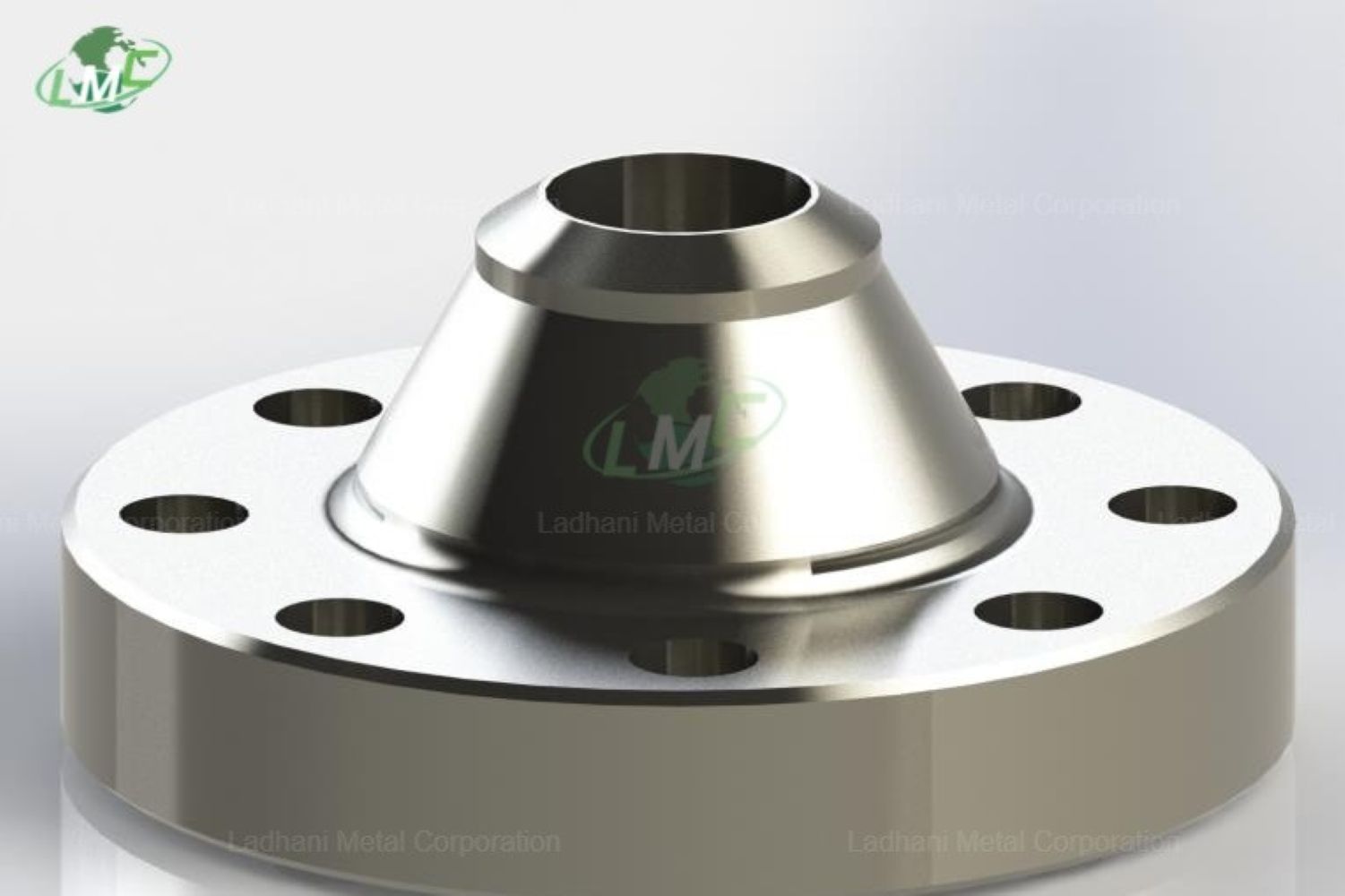

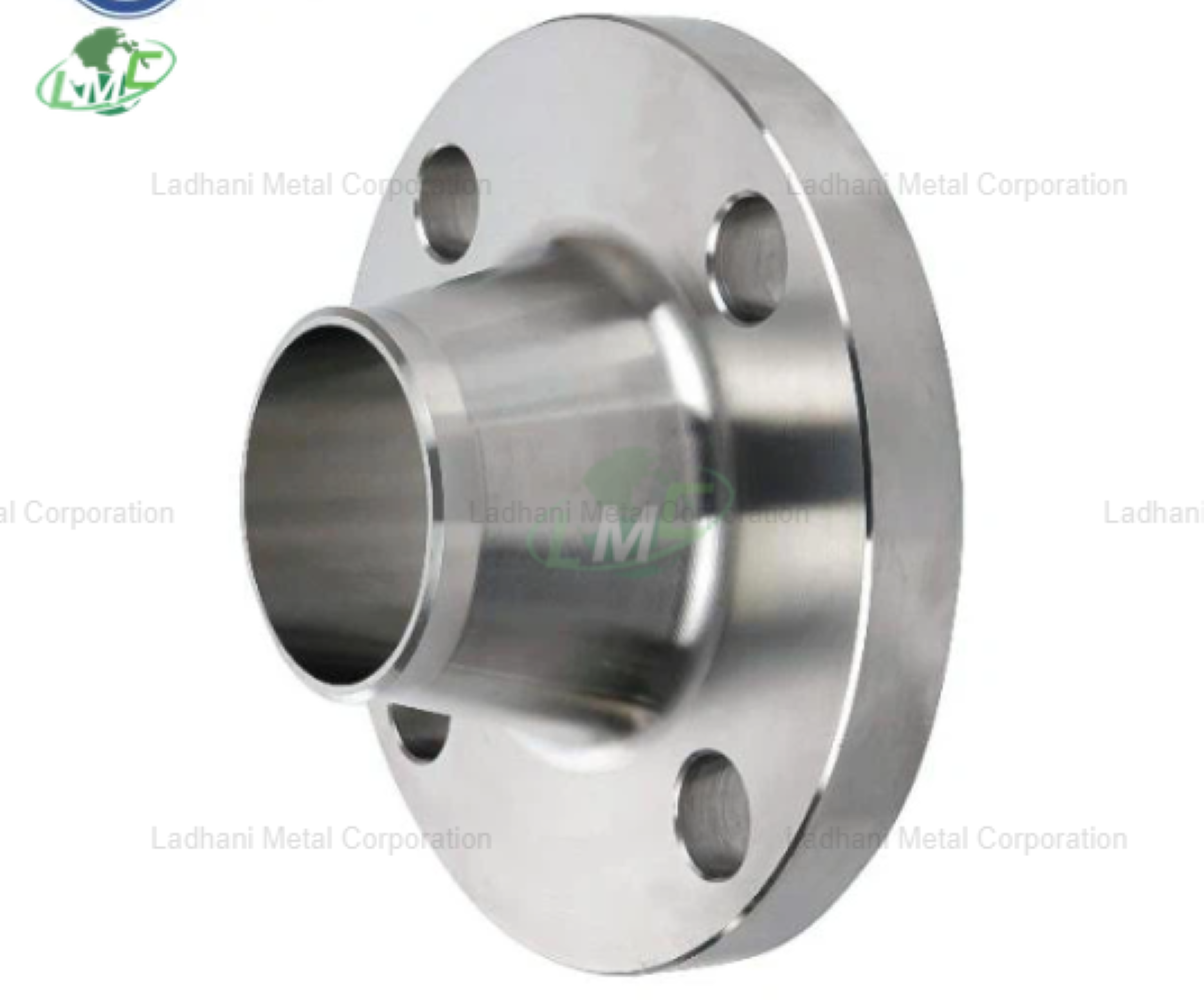

DIN 2543 Monel Flanges are flanges made from Monel, a group of nickel-copper alloys that are known for their excellent corrosion resistance, particularly in marine environments and chemical processing industries. Monel alloys are also highly resistant to acidic and alkaline conditions, which makes them ideal for applications in harsh environments. Material: Typically made from Monel 400 or Monel K-500, which are the most common grades of Monel alloys. Pressure Rating (PN16): Rated for 16 bar (approximately 232 psi) at 20°C (68°F), suitable for medium-pressure systems. Key Features of DIN 2543 Monel Flanges: Corrosion Resistance: Monel alloys, especially Monel 400, are highly resistant to corrosion, including in seawater, acids, and alkaline solutions. This makes them ideal for use in marine, chemical, and offshore oil environments. Strength and Durability: Monel alloys offer high strength and excellent tensile strength even at elevated temperatures. The materials maintain their integrity and resilience in harsh environments, ensuring long-term durability. Weldability: Monel alloys are weldable, but care must be taken during the welding process to ensure that there is no loss of material properties. Proper heat treatment may be required to maintain corrosion resistance and strength. Temperature Resistance: Monel alloys have excellent performance at both high and low temperatures. They can be used in a wide range of environments, including cryogenic temperatures and elevated heat applications. Types of Monel Flanges (DIN 2543): Weld Neck Flanges (WN): These flanges have a tapered neck, which is welded to the pipe. This provides additional strength and is used in applications that require high pressure or high-temperature resistance. Slip-On Flanges (SO): These flanges slide over the pipe and are welded both inside and outside. They are easy to install and commonly used in medium-pressure systems. Blind Flanges (BL): These flanges are used to seal the end of a piping system. They prevent fluid flow and are typically used in applications where future maintenance or modifications may be required. Socket Weld Flanges (SW): These flanges have a socket in which the pipe is inserted and welded. This type is used for small-bore applications in high-pressure systems. Lap Joint Flanges (LJ): These flanges are used with a lap joint stub end and are ideal for systems that require easy alignment and disassembly. They are often used in applications where frequent maintenance is necessary. Common Monel Grades for DIN 2543 Flanges: Monel 400: Composition: Approximately 63% nickel, 29% copper, with small amounts of iron, manganese, and silicon. Properties: Exceptional resistance to corrosion, especially in seawater and other marine environments. Excellent resistance to acids and alkalines, making it suitable for chemical processing applications. High tensile strength and good mechanical properties at both high and low temperatures. Monel K-500: Composition: Similar to Monel 400, but with additional aluminum and titanium, which provide higher strength and greater resistance to corrosion. Pressure Rating (PN16): PN16 refers to the pressure rating of 16 bar (approximately 232 psi) at 20°C (68°F).

Send Message