Inconel Flanges

DIN 2569 Inconel Flanges PN 100 are precision-engineered welding neck flanges manufactured from high-performance Inconel alloys, designed for superior performance in extreme high-temperature, high-pressure, and corrosive industrial applications. Built to DIN 2569 standards, these flanges offer exceptional resistance to oxidation, corrosion, and high-stress environments, making them suitable for critical systems in industries such as aerospace, chemical processing, power generation, marine, and petrochemical.

Ladhani Metal Corporation is a trusted manufacturer and exporter of Inconel flanges, providing products that meet rigorous international standards. The welding neck design ensures reliable, leak-proof connections, ideal for systems that require high strength, thermal stability, and resistance to thermal cycling.

Pressure Rating:

• PN 100 (100 bar / 1450 psi): Specifically designed for high-pressure systems that require outstanding sealing performance, mechanical reliability, and resistance to extreme temperatures and corrosive conditions.

Flange Types:

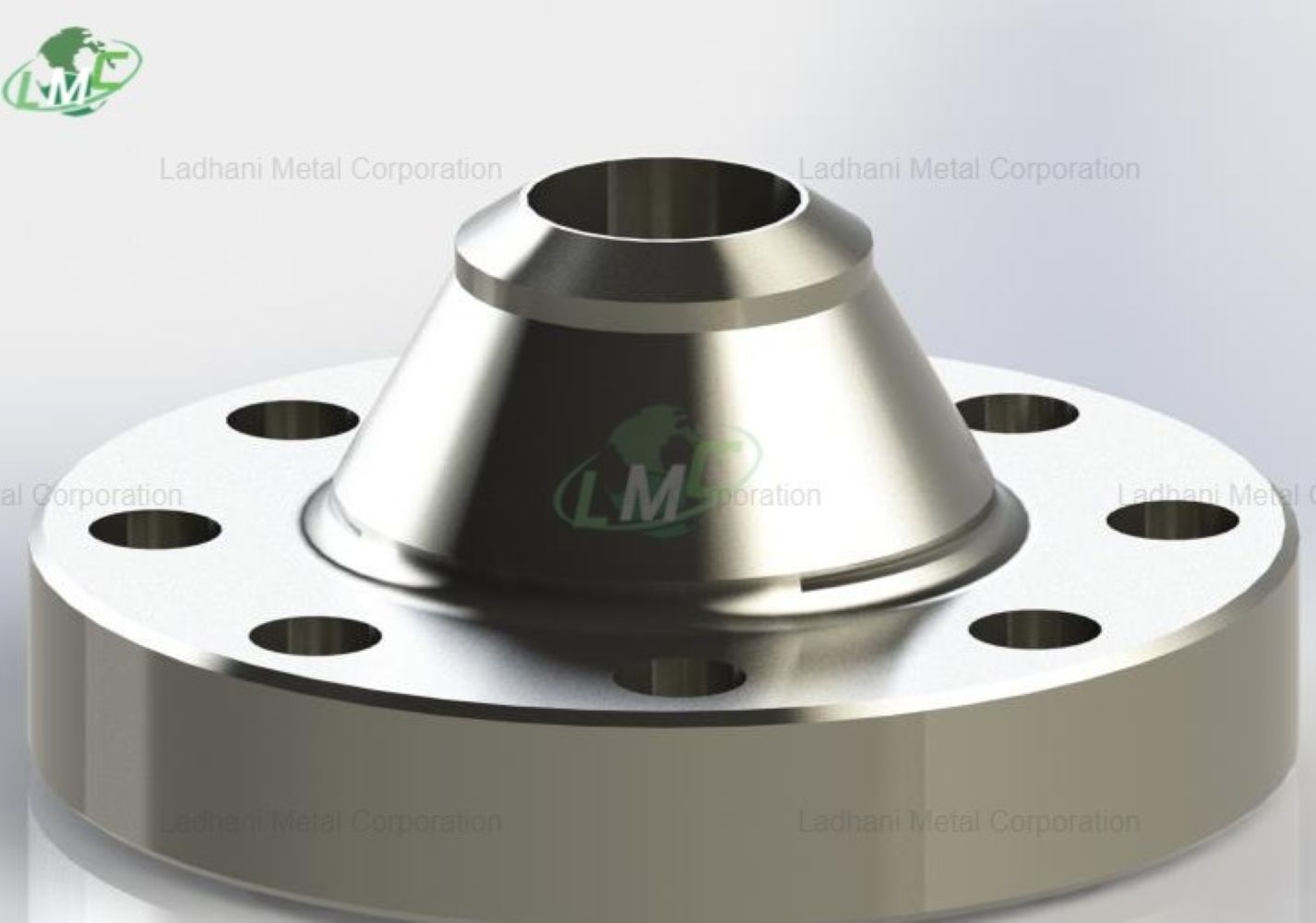

• Welding Neck Flanges

Ensure high-strength, welded connections ideal for systems with continuous pressure, temperature cycles, and mechanical stress.

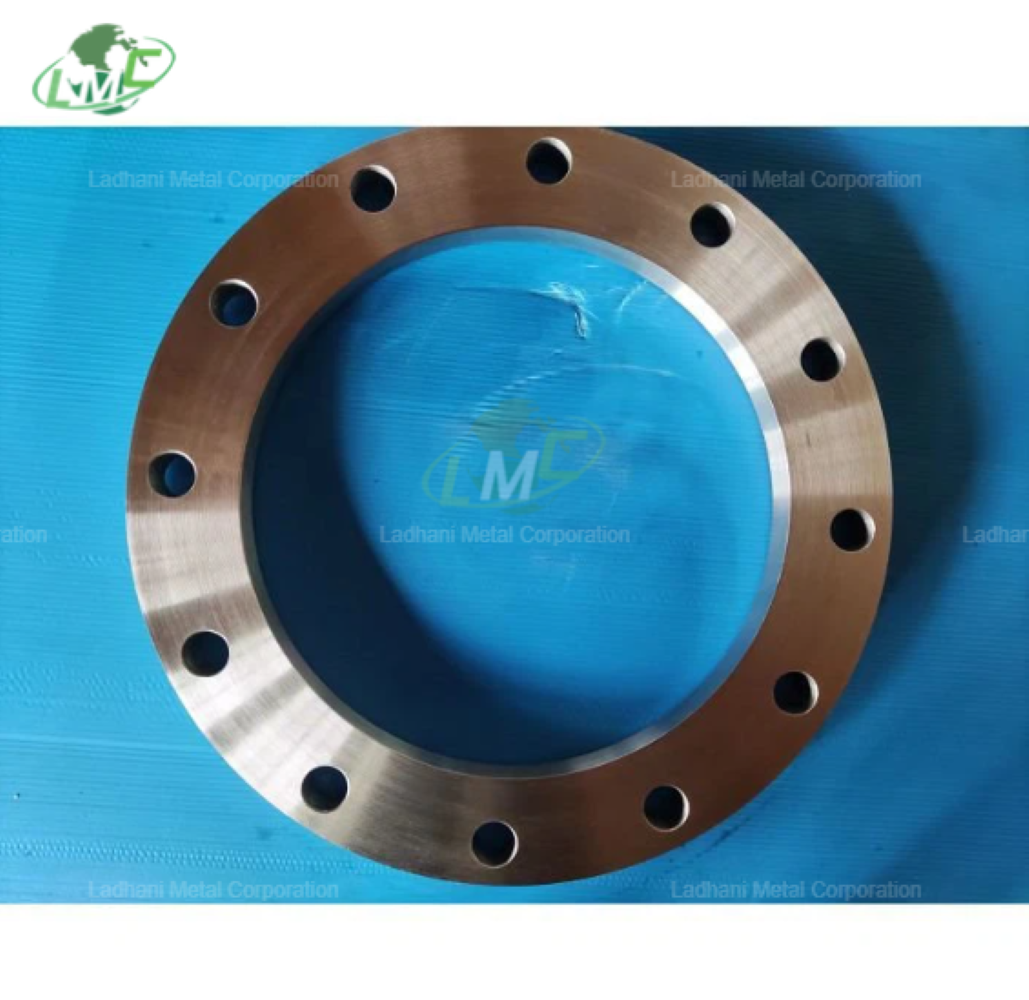

• Raised Face (RF) Flanges

Enhances sealing capability under high-pressure and elevated-temperature conditions.

• Flat Face (FF) Flanges

Used in systems with flat mating surfaces, especially where non-metallic or brittle materials are involved.

• Forged Welding Neck Flanges

Provide enhanced strength, impact resistance, and dimensional precision.

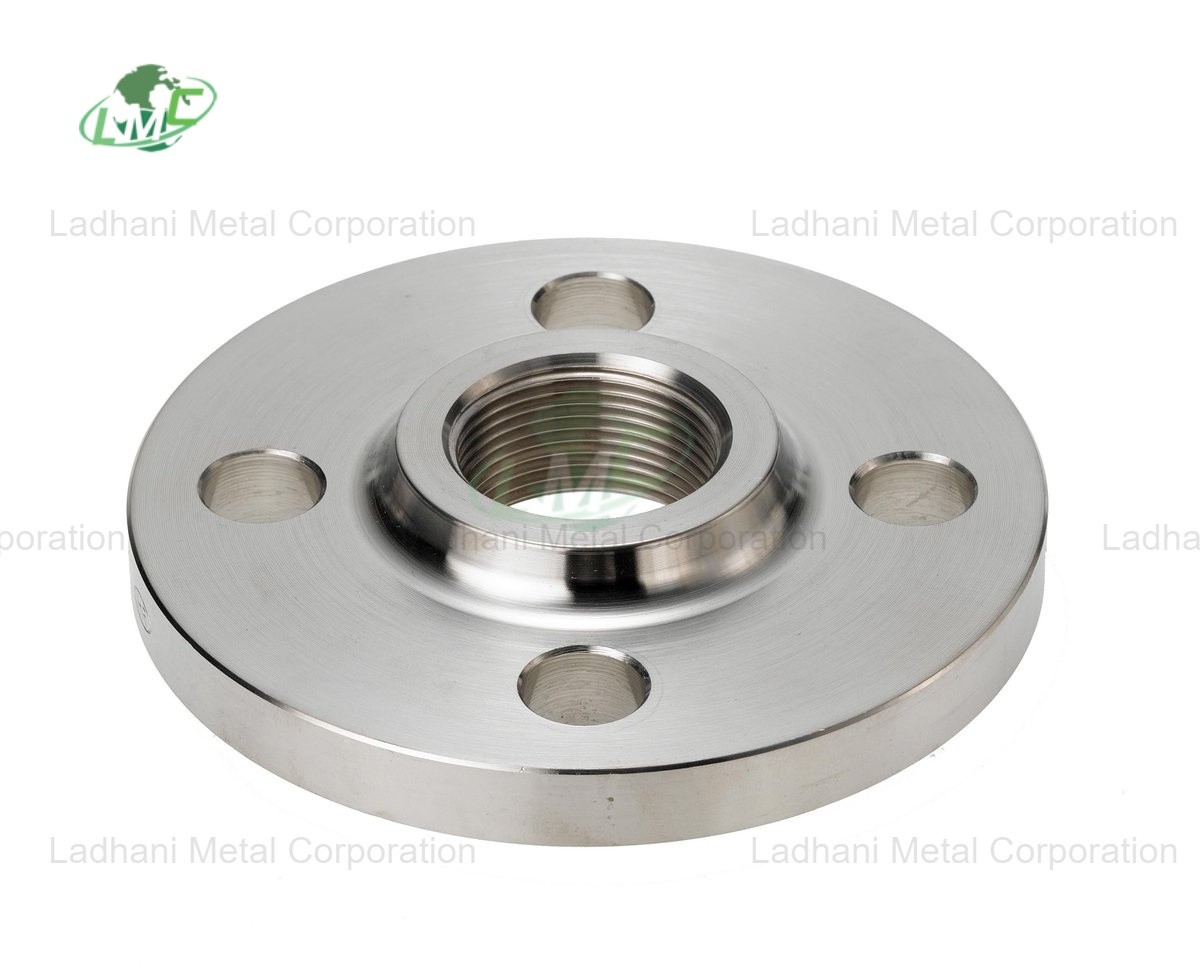

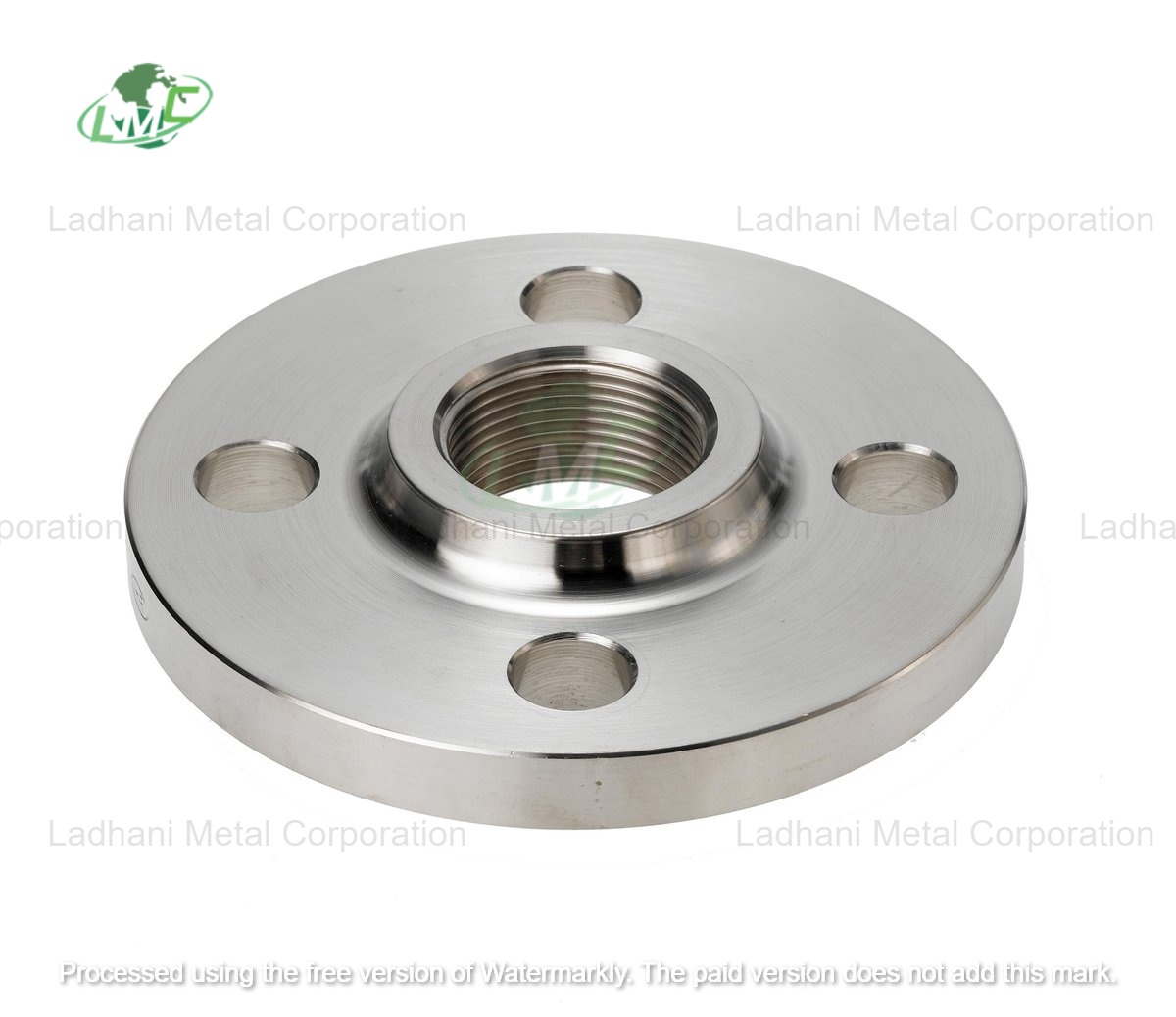

• Custom-Machined Flanges

Available in various sizes, pressure classes, and Inconel grades tailored to customer specifications.

Inconel Grades and Composition:

1. Inconel 600 (Nickel-Chromium Alloy)

Composition:

• Nickel (Ni): Balance

• Chromium (Cr): 14.0 – 17.0%

• Iron (Fe): ≤ 6.0%

• Carbon (C): ≤ 0.15%

• Manganese (Mn): ≤ 1.0%

• Silicon (Si): ≤ 0.50%

Applications:

Commonly used in chemical processing, heat exchangers, and systems exposed to high-temperature oxidation and carburization, as it provides excellent resistance to both oxidation and carburization.

2. Inconel 625 (Nickel-Chromium-Molybdenum Alloy)

Composition:

• Nickel (Ni): Balance

• Chromium (Cr): 20.0 – 23.0%

• Molybdenum (Mo): 8.0 – 10.0%

• Iron (Fe): ≤ 5.0%

Applications:

Ideal for high-stress, high-temperature applications, such as jet engines, rocket motors, and heat exchangers, due to its outstanding fatigue and thermal-fatigue strength.

3. Inconel 718 (Nickel-Chromium Alloy)

Composition:

• Nickel (Ni): Balance

• Chromium (Cr): 17.0 – 21.0%

• Iron (Fe): ≤ 18.0%

• Molybdenum (Mo): 2.8 – 3.3%

• Niobium (Nb): 4.75 – 5.5%

Applications:

Used in highly demanding industries like aerospace and nuclear power generation, Inconel 718 is designed for applications requiring resistance to high-temperature and corrosion environments, along with high strength at elevated temperatures.

Applications of DIN 2569 Inconel Flanges:

• Aerospace and Aviation:

Used in turbine engines, combustion chambers, and exhaust systems due to its ability to withstand high temperatures and oxidative environments.

• Chemical and Petrochemical Plants:

Ideal for processing plants handling aggressive chemicals, where Inconel’s resistance to oxidation and corrosion at high temperatures is critical.

• Power Generation:

Employed in steam turbines, gas turbines, and nuclear reactors where high strength and resistance to thermal expansion are necessary.

• Marine Engineering:

Perfect for seawater exposure and other harsh conditions, making it ideal for shipbuilding and offshore applications.

• Heat Exchangers and Furnace Components:

Used in applications requiring high thermal conductivity and resistance to heat-induced degradation.

Key Features:

• Manufactured to DIN 2569 standard

• Available in PN 100 pressure rating

• Excellent oxidation and corrosion resistance, particularly at high temperatures

• High strength and fatigue resistance, ideal for demanding industrial environments

• Welding neck design ensures permanent, high-integrity connections

• Available with test certificates, quality documentation, and traceability

• Suitable for polishing, pickling, passivation, and custom surface treatments

Conclusion:

DIN 2569 Inconel Flanges PN 100 from Ladhani Metal Corporation are designed for high-performance applications where superior strength, corrosion resistance, and high-temperature stability are required. Whether used in aerospace, petrochemical, power generation, or marine industries, these flanges provide long-lasting and reliable service. Customizable sizes and material grades are available for specific project needs. For further technical consultations or to place an order, contact Ladhani Metal Corporation today.

Price: 0 |

Payment Type: |

Available: False |

COD Available: False |

KYC Status: FAILED

Send Message