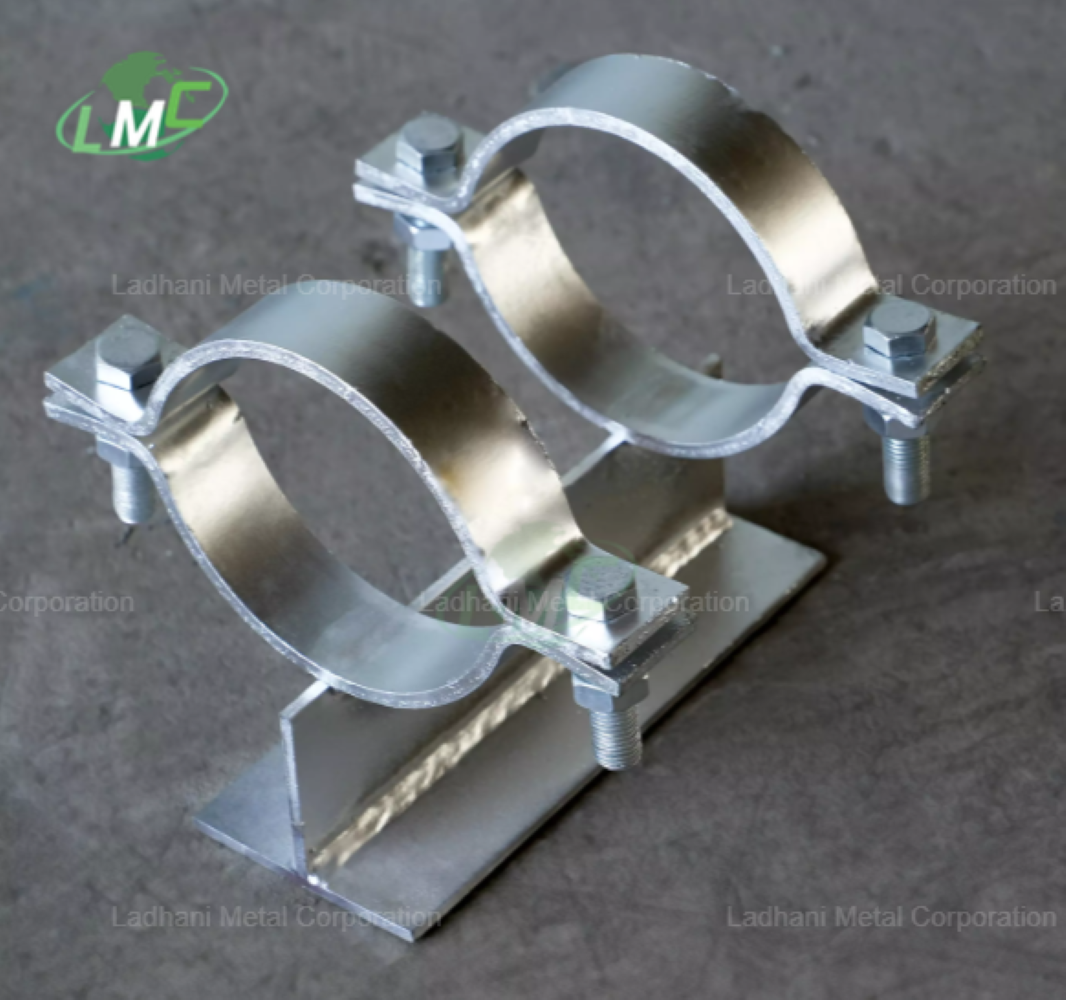

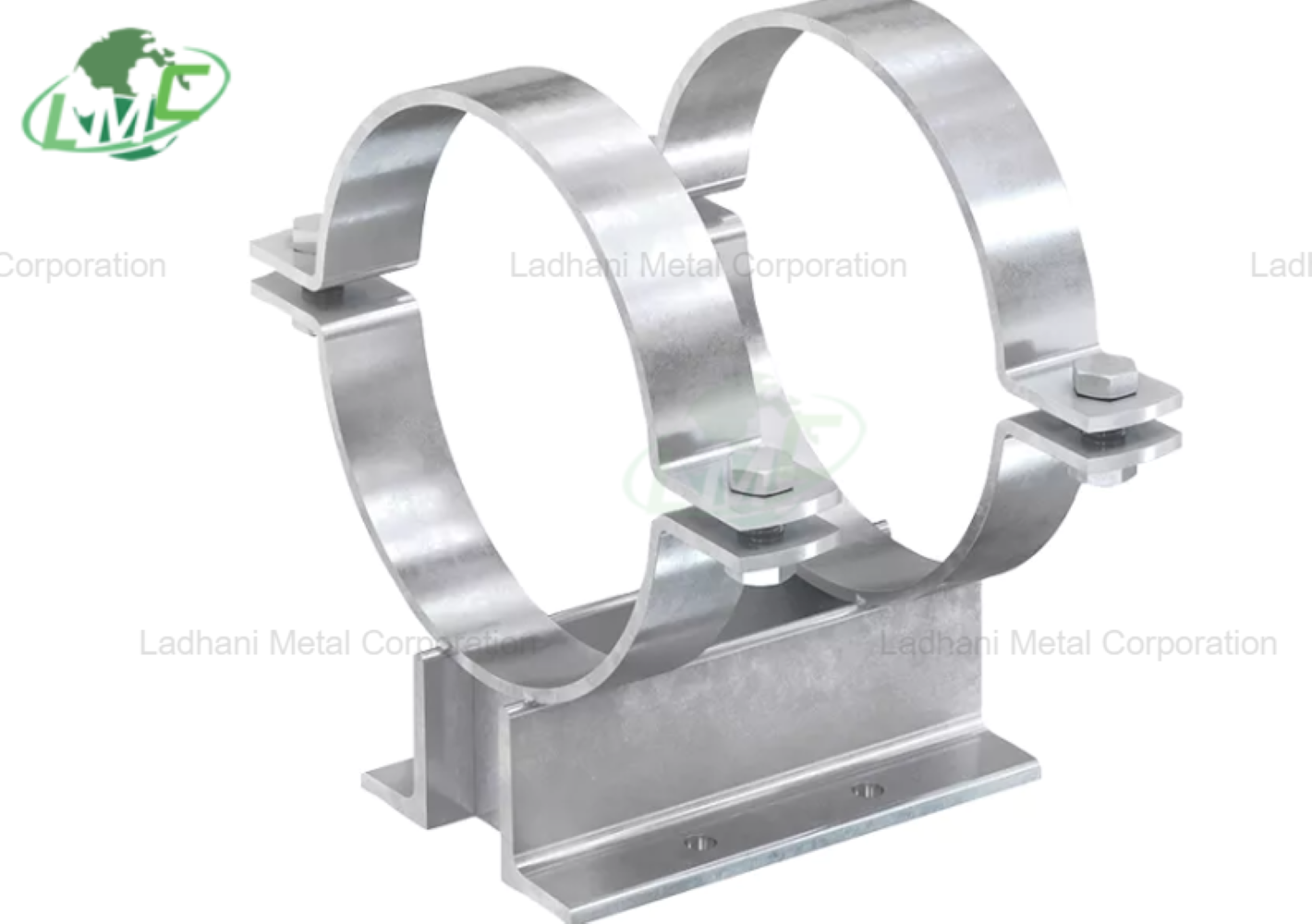

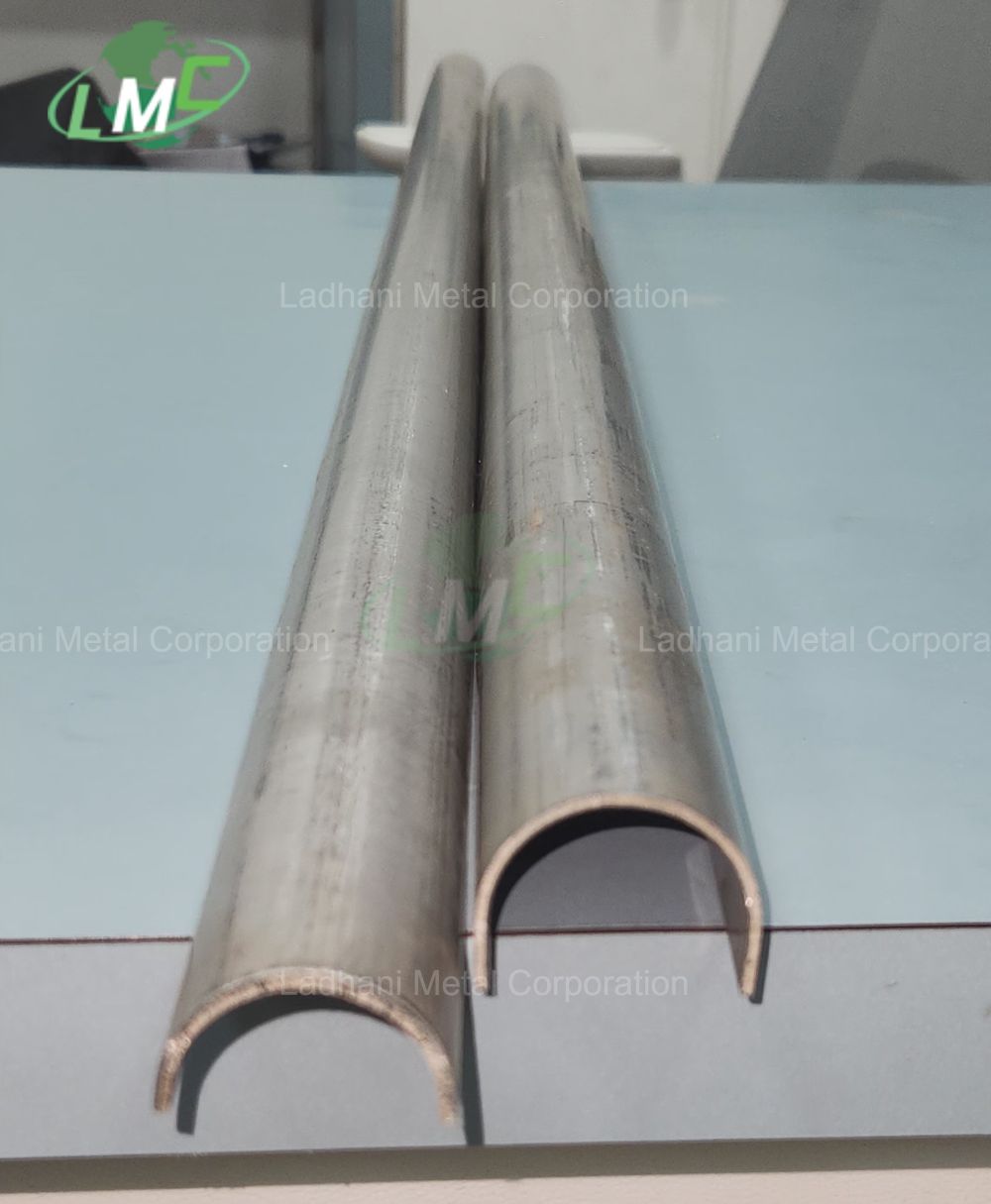

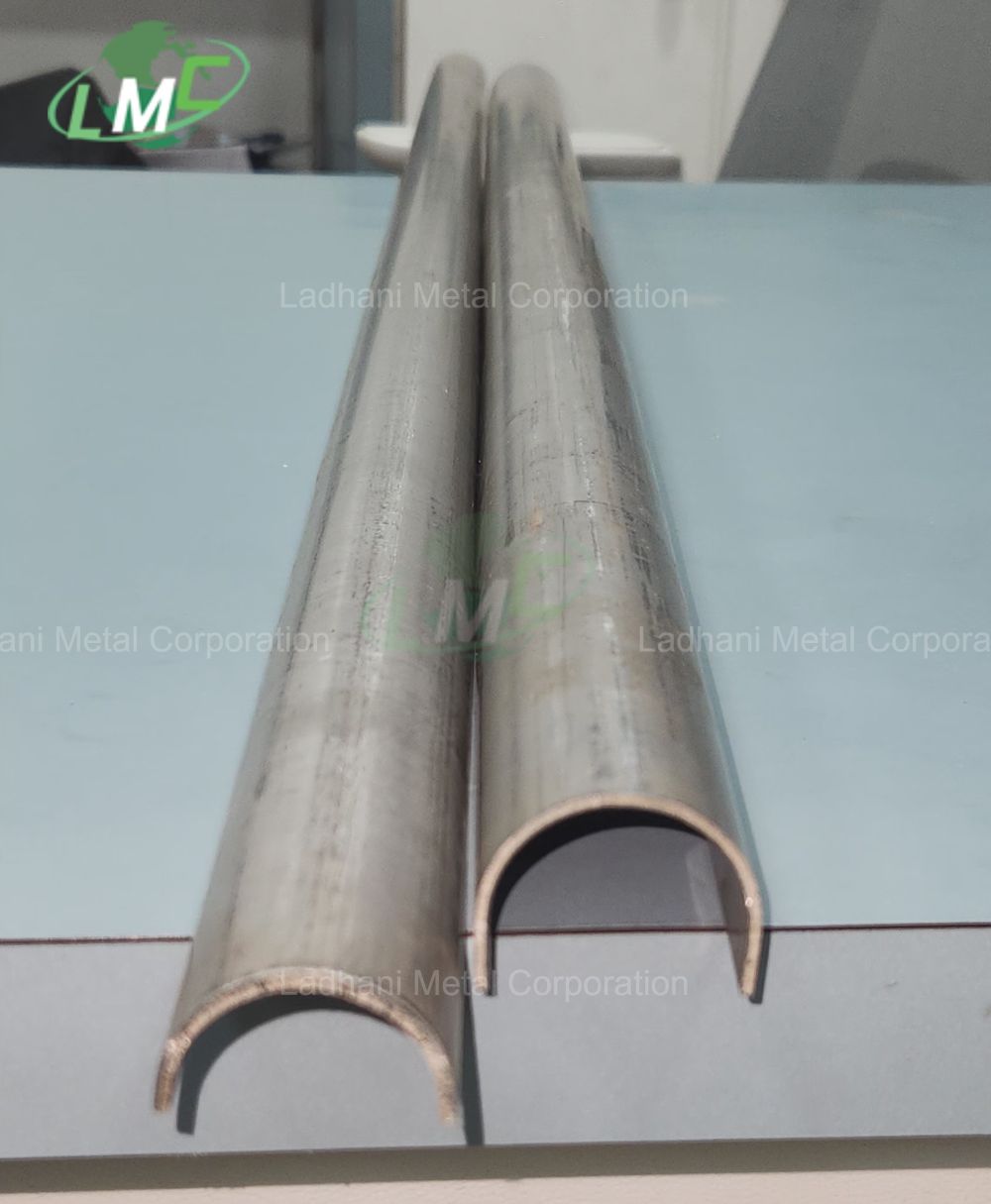

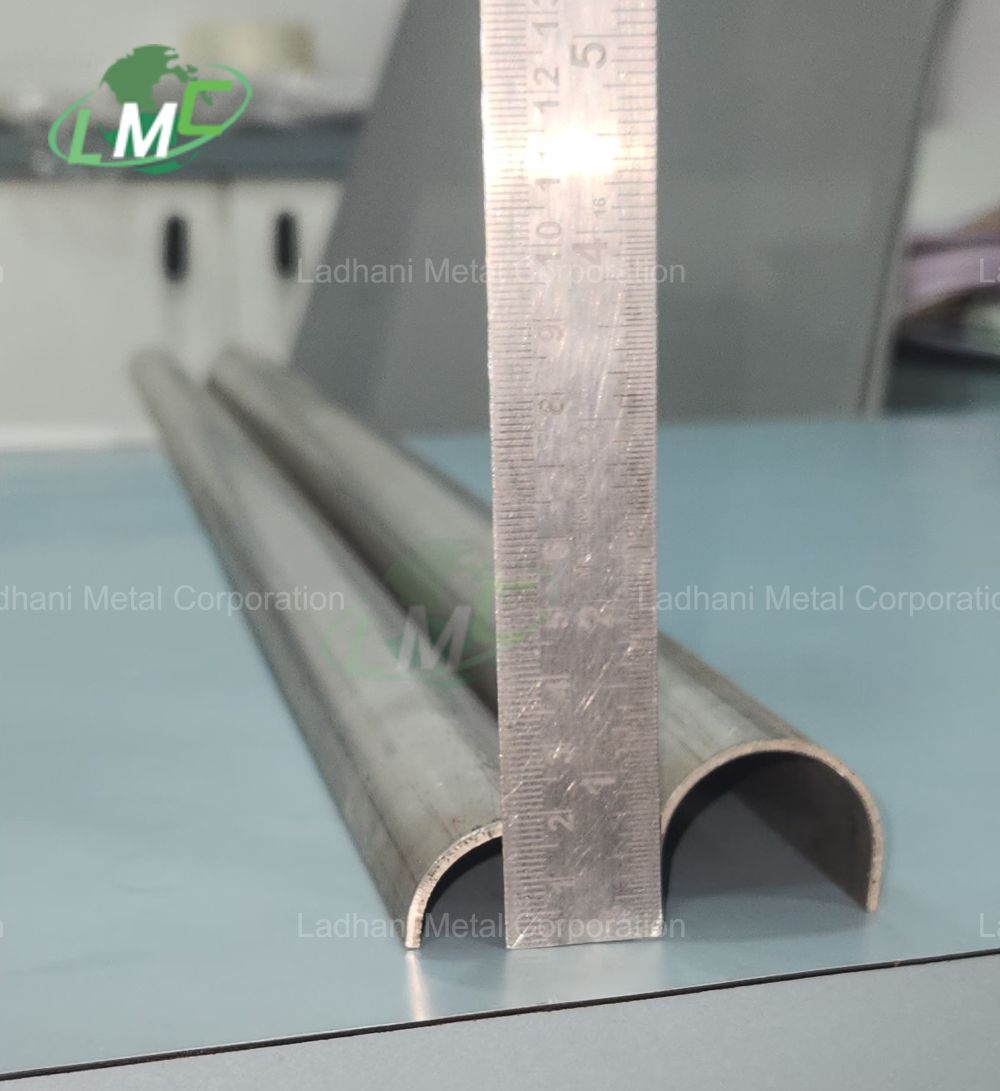

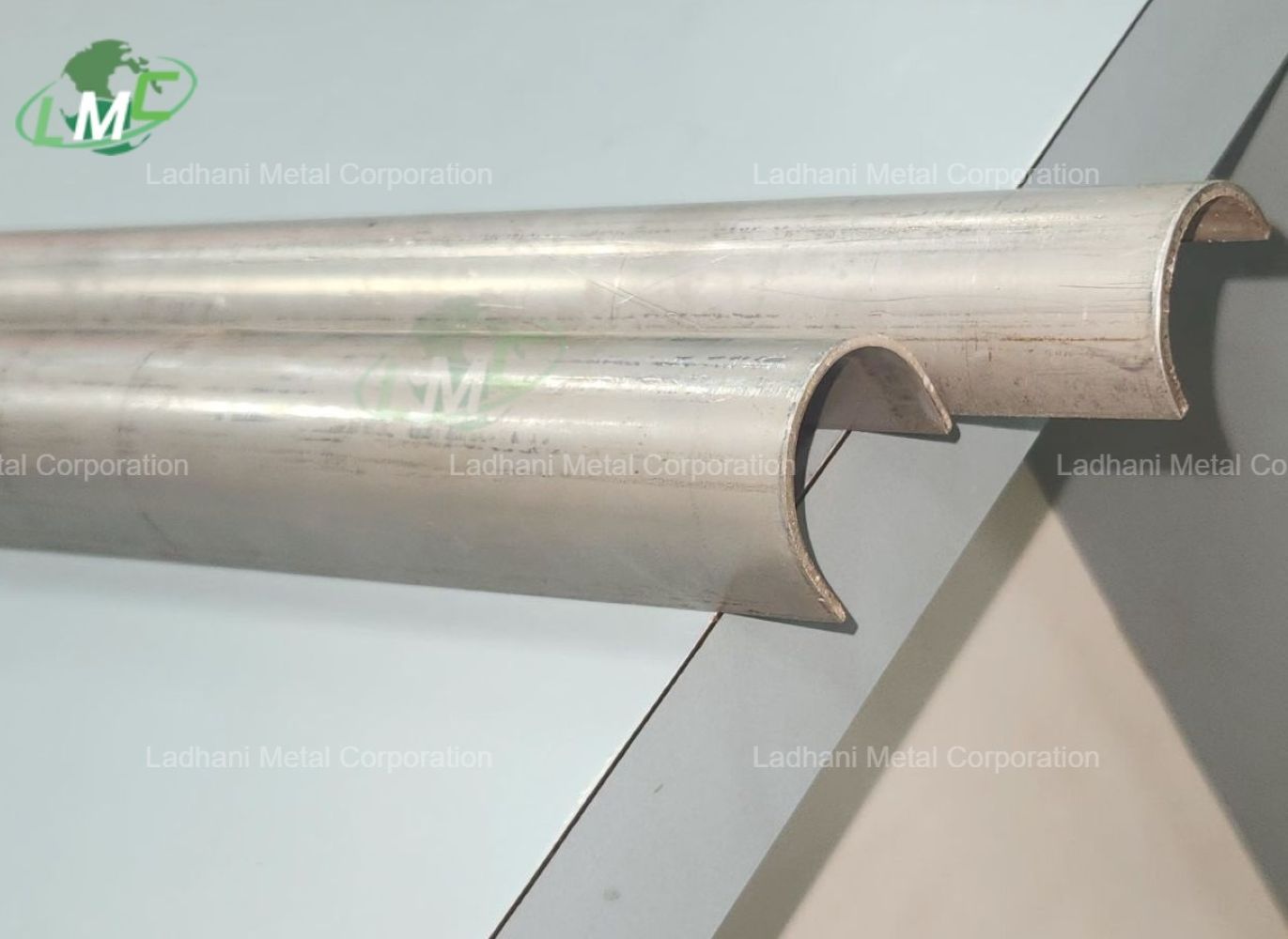

Ladhani Metal Corporation offers SS Sliding Pipe Shoe Clamps designed to support pipelines while allowing smooth axial movement caused by thermal expansion and contraction. These clamps feature a sliding base that enables pipes to move freely without inducing stress on the system or damaging the supporting structure. Manufactured from premium stainless steel, our sliding pipe shoe clamps provide excellent durability, corrosion resistance, and long-term performance in critical industrial applications. Function of SS Sliding Pipe Shoe Clamps • Provide stable support while permitting axial sliding movement • Compensate for thermal expansion and contraction in pipelines • Distribute pipe loads evenly to prevent localized stress and wear • Reduce vibration, noise, and fatigue in piping systems • Prevent direct contact with corrosive or abrasive supporting surfaces Ladhani Metal Corporation manufactures, supplies, and exports SS Sliding Pipe Shoe Clamps in a wide range of sizes and finishes, meeting both domestic and international project requirements. Available Grades • SS 304 • SS 304L • SS 316 • SS 316L Applications Widely used in industries where pipelines undergo movement due to thermal or dynamic conditions. • Refineries and petrochemical plants • Fertilizer and chemical processing units • Oil and gas transmission pipelines • Power generation plants and boilers • Marine and offshore engineering installations Uses • Provides sliding support for pipelines with thermal movement • Protects pipelines from stress and structural deformation • Enhances operational safety and system efficiency • Maintains insulation and structural integrity of pipelines • Suitable for high-temperature and heavy-duty applications Features • Sliding design for controlled pipeline movement • High load-bearing strength and robust construction • Excellent resistance to corrosion and oxidation • Long service life with minimal maintenance requirements • Manufactured in SS 304, 304L, 316, and 316L grades Conclusion The SS Sliding Pipe Shoe Clamp from Ladhani Metal Corporation is a reliable solution for pipelines that require support with controlled axial movement. Available in SS 304, SS 304L, SS 316, and SS 316L grades, these clamps ensure strength, durability, and corrosion resistance, making them suitable for diverse industrial pipeline systems. For inquiries or project requirements, contact Ladhani Metal Corporation #Mumbai #Delhi #Bangalore #Hyderabad #Chennai #Kolkata #Pune #Ahmedabad #Surat #Vadodara #Rajkot #Nagpur #Indore #Bhopal #Jaipur #Lucknow #Kanpur #Patna #Ranchi #Jamshedpur #Bhubaneswar #Raipur #Visakhapatnam #Vijayawada #Coimbatore #Madurai #Kochi #Trivandrum #Tiruchirappalli #Mangalore #Mysore #Noida #Gurgaon #Faridabad #Ghaziabad #Ludhiana #Amritsar #Chandigarh #Jalandhar #Agra #Varanasi #Meerut #Aurangabad #Nashik #Solapur #Gwalior #Allahabad #Guwahati #Shillong #PipeShoeClamp #StainlessSteelPipeShoeClamp #SSPipeShoeClamp #PipeShoeClampManufacturer #PipeShoeClampSupplier #PipeShoeClampExporter #PipeShoeClampIndia #IndustrialPipeShoeClamp #HeavyDutyPipeShoeClamp #CustomPipeShoeClamp #HighQualityPipeShoeClamp #304PipeShoeClamp #316PipeShoeClamp #304LPipeShoeClamp #316LPipeShoeClamp #PipeShoeClampFittings #PipeShoeClampSupport #SS304PipeShoeClamp #SS316PipeShoeClamp #SS316LPipeShoeClamp #SS304LPipeShoeClamp #PipeShoeClampDesign #PipeShoeClampApplication #PipeShoeClampForBoilers #PipeShoeClampForRefinery #PipeShoeClampForPetrochemical #PipeShoeClampForPowerPlant #PipeShoeClampForOilAndGas #PipeShoeClampForChemicalPlant #PipeShoeClampSolutions #PipeShoeClampProducts #PipeShoeClampFabrication #PipeShoeClampInstallation #PipeShoeClampSupportSystem #PipeShoeClampAssembly #PipeShoeClampHardware #PipeShoeClampTechnology #DurablePipeShoeClamp #ReliablePipeShoeClamp #PipeShoeClampStockist #PipeShoeClampWholesale #PipeShoeClampTrading #PipeShoeClampDistribution #PipeShoeClampExports #PipeShoeClampWorldwide #PipeShoeClampIndustry #PipeShoeClampMarket #PipeShoeClampOnline #PipeShoeClampComponents #PipeShoeClampSystems

Send Message