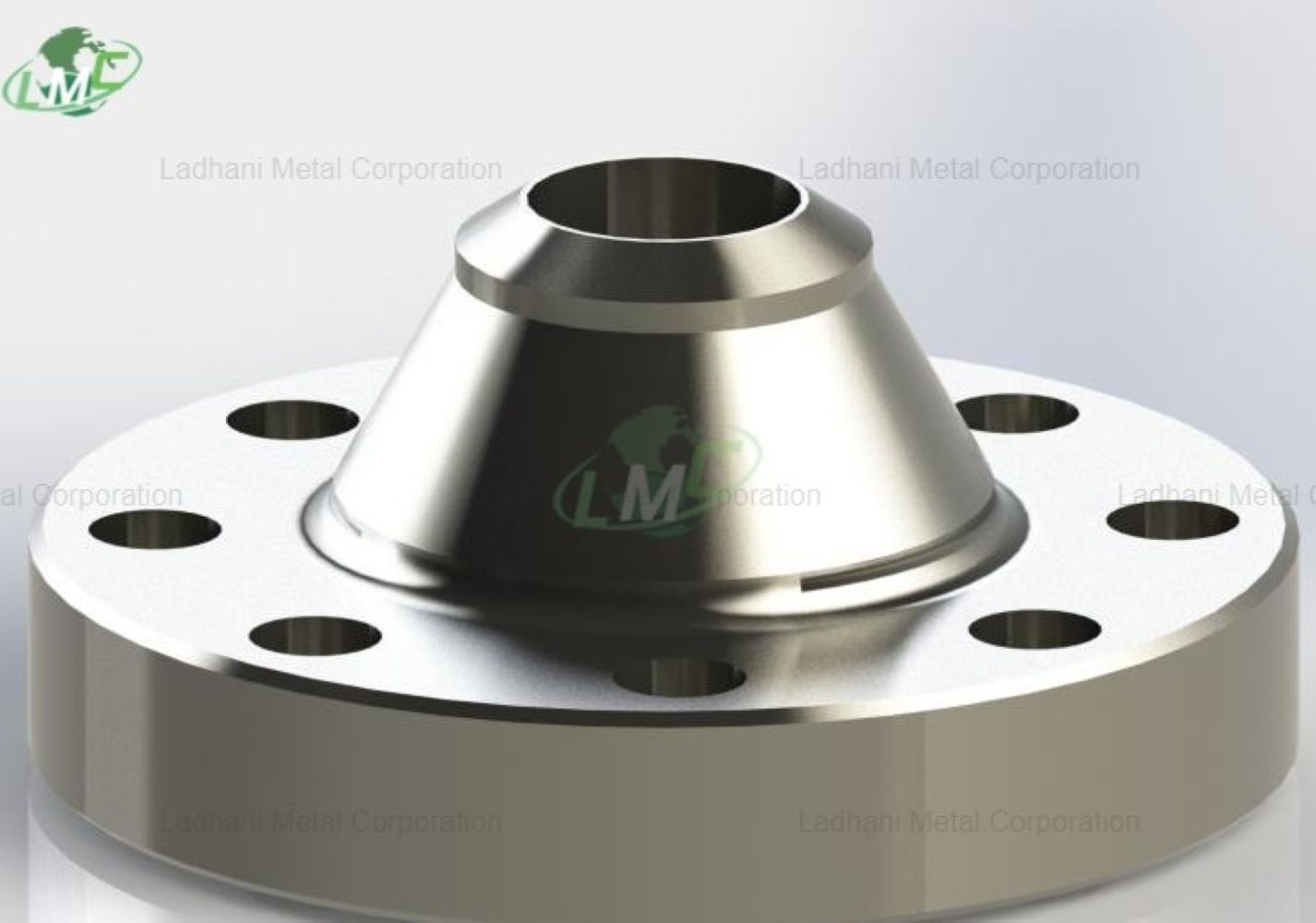

Stainless Steel Flanges

DIN 2634 stainless steel flanges PN 25 are precision-engineered weld neck flanges designed and manufactured in accordance with the DIN 2634 standard. These flanges are suitable for high-pressure pipeline systems operating up to 25 bar (362 psi), providing robust and secure connections for a variety of critical industrial applications. Constructed from high-quality stainless steel grades such as 304, 316, and 321, these flanges offer excellent mechanical properties, enhanced corrosion resistance, and dependable performance in aggressive service conditions.

Ladhani Metal Corporation is a globally recognized manufacturer and supplier of stainless steel flanges, known for delivering high-precision products that meet stringent international quality and dimensional standards. Each flange undergoes rigorous testing and quality checks to ensure optimal performance, safety, and longevity under high-pressure conditions.

Pressure Rating:

• PN 25 (25 bar / 362 psi): Engineered for high-pressure environments requiring reinforced flange connections with reliable resistance to corrosion and mechanical stress.

Flange Type:

• Weld Neck Flanges

Incorporating a long tapered hub, weld neck flanges help maintain pipe alignment, reduce stress concentration at the weld joint, and enable smooth fluid flow with minimal turbulence.

• Flat Face (FF) Flanges

Ideal for systems utilizing soft gaskets or cast components, flat face flanges promote consistent gasket compression and sealing integrity.

Stainless Steel Grades and Typical Composition:

Stainless Steel 304

• Chromium (Cr): 18.0 – 20.0%

• Nickel (Ni): 8.0 – 10.5%

• Carbon (C): ≤ 0.08% (304), ≤ 0.03% (304L)

• Manganese (Mn): ≤ 2.0%

• Silicon (Si): ≤ 1.0%

• Phosphorus (P): ≤ 0.045%

• Sulfur (S): ≤ 0.03%

• Iron (Fe): Balance

Applications: Suitable for general-purpose piping systems in environments with moderate corrosion exposure, including potable water and light-duty process lines.

Stainless Steel 316

• Chromium (Cr): 16.0 – 18.0%

• Nickel (Ni): 10.0 – 14.0%

• Molybdenum (Mo): 2.0 – 3.0%

• Carbon (C): ≤ 0.08% (316), ≤ 0.03% (316L)

• Manganese (Mn): ≤ 2.0%

• Silicon (Si): ≤ 1.0%

• Phosphorus (P): ≤ 0.045%

• Sulfur (S): ≤ 0.03%

• Iron (Fe): Balance

Applications: Ideal for systems exposed to chlorides, cleaning agents, or other corrosive substances such as in chemical processing, pharmaceuticals, and marine environments.

Stainless Steel 321

• Chromium (Cr): 17.0 – 19.0%

• Nickel (Ni): 9.0 – 12.0%

• Titanium (Ti): ≥ 5 × C (typically 0.20 – 0.70%)

• Carbon (C): ≤ 0.08%

• Manganese (Mn): ≤ 2.0%

• Silicon (Si): ≤ 1.0%

• Phosphorus (P): ≤ 0.045%

• Sulfur (S): ≤ 0.03%

• Iron (Fe): Balance

Applications: Frequently used in high-temperature services such as thermal processing equipment, exhaust systems, and heat exchangers due to its stability against intergranular corrosion.

Applications of DIN 2634 Stainless Steel Flanges PN 25:

• Chemical Processing Units

Handles higher operating pressures in systems transporting acids, alkalis, and solvents.

• Marine and Offshore Installations

Resistant to pressure fluctuations and saltwater corrosion in offshore piping networks.

• Pharmaceutical and Biotech Plants

Used in clean process environments where both pressure integrity and corrosion resistance are critical.

• Industrial Steam and Thermal Systems

Suitable for steam distribution and thermal expansion pipelines operating under high pressure.

• Power Generation Facilities

Applied in turbine piping, heat recovery systems, and pressurized cooling water circuits.

Key Features:

• Manufactured to DIN 2634 dimensional and pressure specifications

• PN 25 pressure rating supports high-pressure operation

• Weld neck design ensures leak-tight, stress-resistant connections

• Available in stainless steel grades 304, 316, 321 and their low-carbon variants

• Superior resistance to high-temperature corrosion and chemical attack

• Long-term mechanical strength and fatigue resistance

• Custom sizes, finishes, and pressure ratings available upon request

Conclusion:

DIN 2634 stainless steel flanges PN 25 from Ladhani Metal Corporation are engineered for high-performance use in high-pressure industrial environments where safety, corrosion resistance, and durability are paramount. These flanges are ideal for chemical, marine, thermal, and high-purity applications requiring strong, leak-resistant, and corrosion-resistant connections. For technical support, customized solutions, or pricing details, contact Ladhani Metal Corporation today.

Send

Message