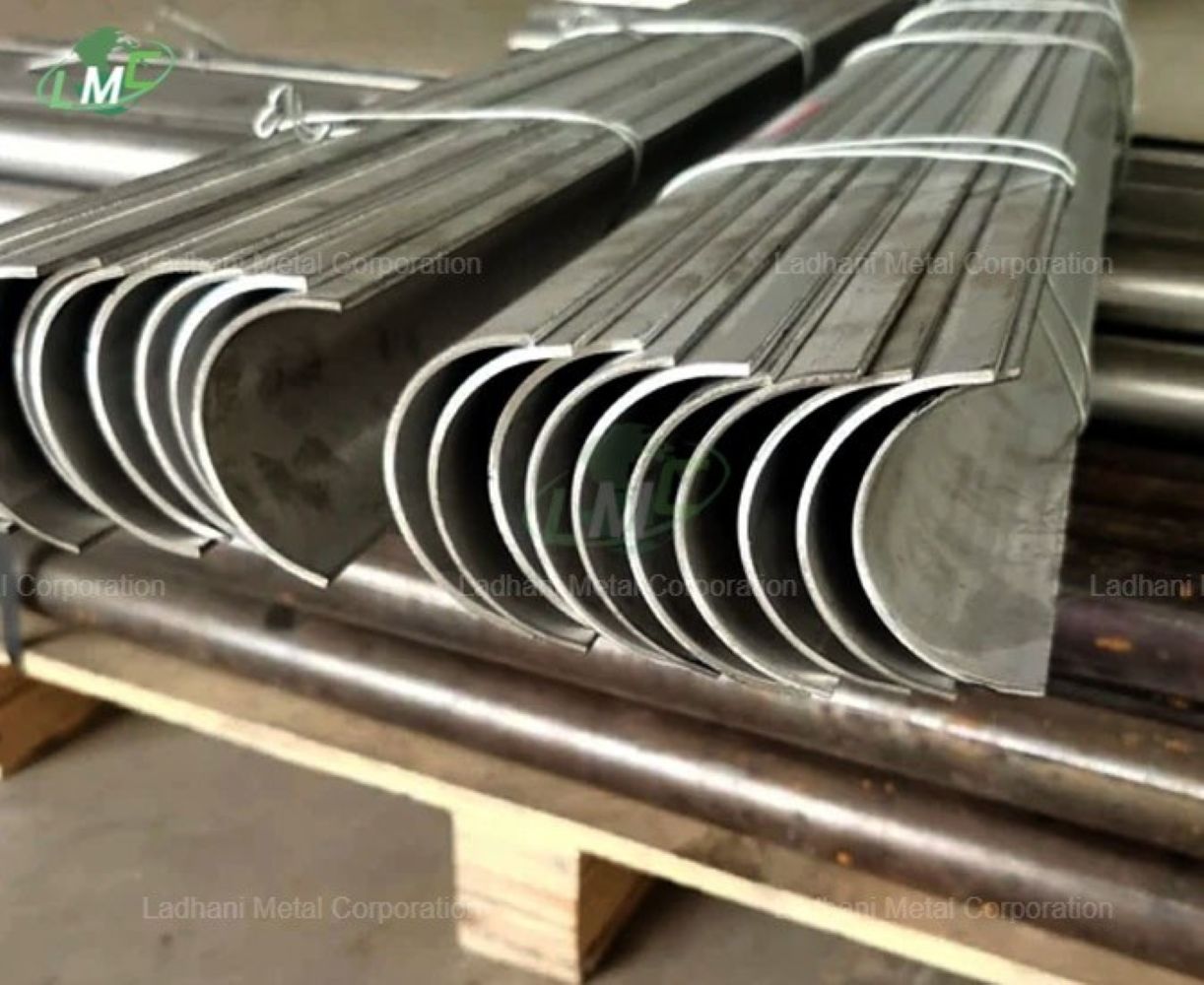

Half Round Tube Shield Half Round Tube Shields by Ladhani Metal Corporation are purpose-built components designed to extend the life of boiler, heat exchanger, and process tubes by offering robust protection from erosion, scaling, and thermal impact. These shields are essential for maintaining system performance and reducing unscheduled downtime in industries that operate under demanding thermal and mechanical conditions. SS 420 Half Round Tube Shield The SS 420 Half Round Tube Shield is a semi-cylindrical protector fabricated from martensitic stainless steel grade 420. Known for its high hardness, wear resistance, and moderate corrosion resistance, SS 420 is ideally suited for applications where abrasion and mechanical stress are predominant concerns. The half-round configuration ensures a secure fit over existing tubes, creating a physical barrier against direct exposure to high-velocity gases, fly ash, and thermal shocks. Its ability to retain strength at elevated temperatures makes it suitable for use in utility boilers, air preheaters, and other high-wear process systems. Chemical Composition of SS 420 – Martensitic Stainless Steel • Carbon (C): 0.15 – 0.40% • Manganese (Mn): ≤ 1.00% • Phosphorus (P): ≤ 0.040% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 12.0 – 14.0% • Nickel (Ni): ≤ 0.75% • Iron (Fe): Balance Uses • Boiler Tube Protection – Provides abrasion resistance in flue gas paths, soot blower zones, and areas exposed to particulate erosion in industrial boilers. • Heat Exchanger Shielding – Minimizes mechanical damage caused by turbulent flow and particulate-laden fluids, preserving heat transfer efficiency. • Furnace Tube Guarding – Protects furnace and kiln tubes from thermal scale buildup and flame impingement in harsh operating zones. • Steam and Condensate Systems – Shields tubes from vibration, pressure cycling, and moderate steam-induced corrosion. • Ash and Gas Flow Zones – Ideal for protecting tubes in areas of fly ash impact or high-speed combustion gas flow in WTE and biomass plants. Features • High Surface Hardness – Excellent resistance to surface wear, impact, and mechanical abrasion due to its high carbon and martensitic structure. • Moderate Corrosion Resistance – Withstands oxidizing and mildly corrosive conditions up to 650°C, suitable for moderate industrial atmospheres. • Structural Integrity – Maintains strength under pressure and temperature cycling, offering long service life in mechanical protection roles. • Easy Installation – The half-round design enables fast application in the field with minimal disruption to tube layout or operation. • Finishing Options – Available in bright annealed, pickled, or passivated surfaces depending on operational requirements. • Custom Built – Offered in varied lengths, diameters, thicknesses, and attachment styles (clamp-on or weld-on) to match specific installations. Applications • Thermal and Biomass Power Stations – Used to protect boiler tubes from ash erosion and gas turbulence in high-velocity flue paths. • Cement and Steel Industries – Shields kiln and heat recovery tubes from particulate impact, slag, and high-temperature dust environments. • Waste-to-Energy Plants – Guards tubes in combustion chambers and economizers where gas stream erosion and soot buildup are persistent issues. • Oil Refineries – Applied in heat exchangers and preheater tubes exposed to abrasive flow or moderate corrosion risk. • Pulp and Paper Mills – Used in black liquor recovery boilers and steam generators handling fibrous or corrosive waste products. • Air Preheaters – Ideal for tubes located in dust-laden environments requiring protection against wear and gas abrasion. Conclusion The SS 420 Half Round Tube Shield from Ladhani Metal Corporation offers a high-performance, wear-resistant solution for tube protection in mechanically aggressive and thermally intensive environments. Its martensitic structure provides outstanding surface hardness, making it especially effective in soot blower zones, high-velocity ducts, and areas subject to abrasive particle flow. While not intended for severe chemical environments, SS 420 delivers exceptional value where mechanical durability is the top priority. With full customization options and precision manufacturing, Ladhani Metal Corporation ensures durable, reliable shielding products tailored to your plant’s exact operational needs. For technical consultations, order customization, or to request a quotation, please contact Ladhani Metal Corporation.

Send Message