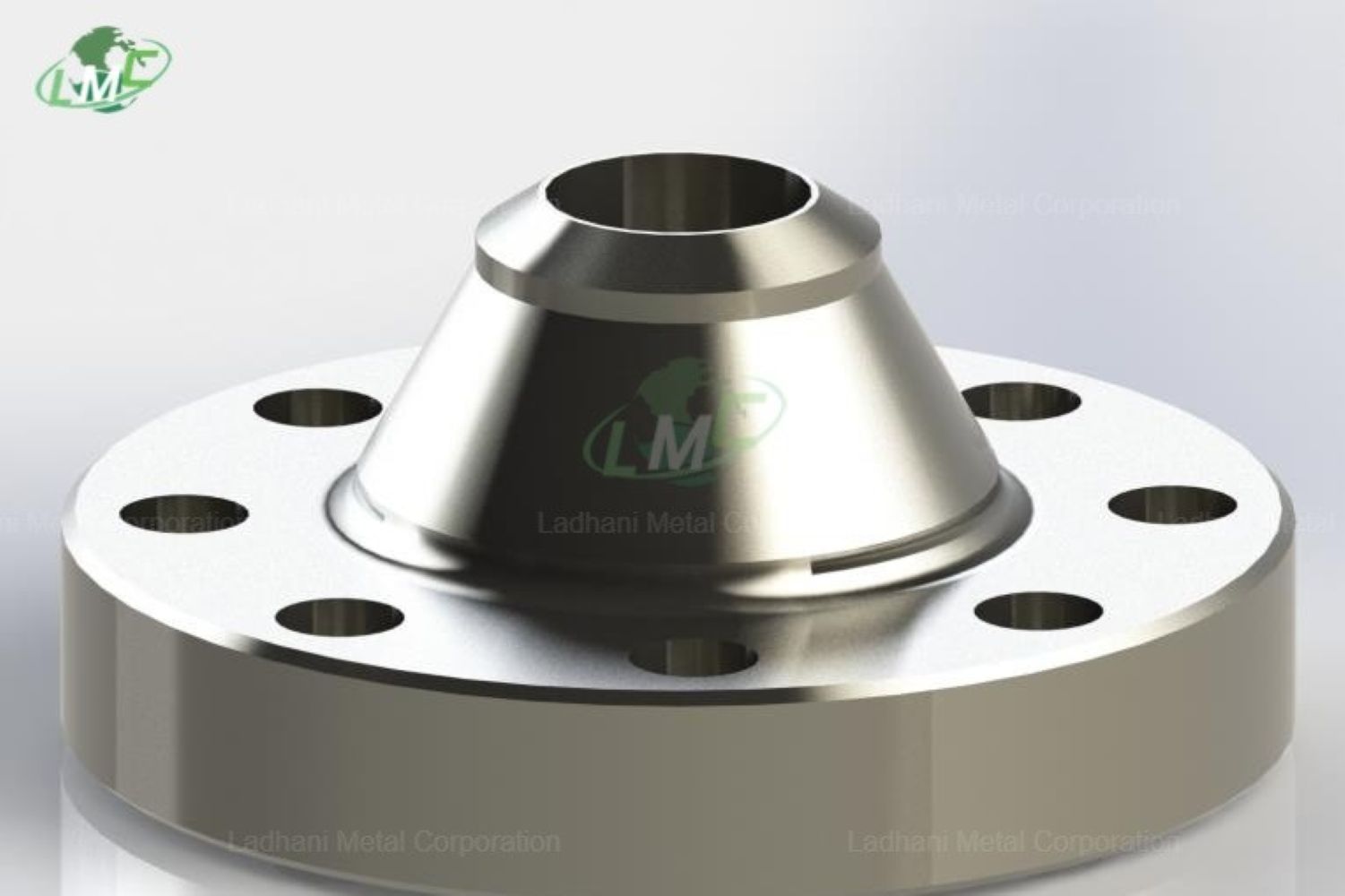

DIN 2633 super duplex steel flanges PN 16 are high-performance weld neck flanges manufactured in accordance with the DIN 2633 standard. Engineered for medium-pressure piping systems with a pressure rating of up to 16 bar (232 psi), these flanges are made from super duplex stainless steels, which offer a superior combination of high mechanical strength and outstanding corrosion resistance. They are specifically designed for critical applications in aggressive environments where standard stainless or duplex steels may not provide sufficient durability. Ladhani Metal Corporation is a globally recognized manufacturer and supplier of super duplex steel flanges, known for precision manufacturing, strict quality control, and compliance with international material and dimensional standards. Each flange is tested for performance, safety, and resistance to harsh operating conditions. Pressure Rating: • PN 16 (16 bar / 232 psi): Suitable for systems requiring secure, corrosion-resistant, and high-strength connections under moderate pressure. Flange Type: • Weld Neck Flanges Featuring a long tapered hub, these flanges offer optimal stress distribution, reduce turbulence at the joint, and ensure reliable pipe alignment in high-stress environments. • Flat Face (FF) Flanges Designed for uniform gasket compression, particularly effective when used with soft gaskets or cast iron mating components. Super Duplex Steel Grades and Full Composition: Super Duplex 2507 (UNS S32750) • Chromium (Cr): 24.0 – 26.0% • Nickel (Ni): 6.0 – 8.0% • Molybdenum (Mo): 3.0 – 5.0% • Nitrogen (N): 0.24 – 0.32% • Manganese (Mn): ≤ 1.2% • Silicon (Si): ≤ 0.8% • Carbon (C): ≤ 0.03% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.02% • Iron (Fe): Balance Applications: Ideal for offshore platforms, subsea systems, desalination plants, chemical process systems, and high-chloride environments requiring superior corrosion and pitting resistance. Super Duplex S32760 • Chromium (Cr): 24.0 – 26.0% • Nickel (Ni): 6.0 – 8.0% • Molybdenum (Mo): 3.0 – 4.0% • Tungsten (W): 0.5 – 1.0% • Copper (Cu): 0.5 – 1.0% • Nitrogen (N): 0.2 – 0.3% • Carbon (C): ≤ 0.03% • Iron (Fe): Balance Applications: Commonly used in seawater systems, heat exchangers, fire-fighting systems, and oil & gas equipment due to excellent resistance to erosion, stress corrosion cracking, and fatigue. Applications of DIN 2633 Super Duplex Steel Flanges PN 16: • Offshore Oil and Gas Platforms Resists chloride-induced corrosion and high mechanical loads in topside and subsea installations. • Desalination and Marine Systems Performs well in high-salinity environments where other alloys may suffer from pitting or crevice corrosion. • Chemical and Petrochemical Plants Suitable for handling strong acids, caustic solutions, and oxidizing environments at elevated temperatures and pressures. • Fire Protection and Water Injection Systems Ensures reliability and corrosion resistance in safety-critical and high-pressure fluid delivery systems. • Pulp and Paper Industry Used in bleach plant systems and recovery boilers where exposure to corrosive agents is routine. Key Features: • Manufactured in compliance with DIN 2633 standards • PN 16 pressure rating for medium-pressure service • Weld neck design ensures secure, vibration-resistant connections • Available in high-strength super duplex grades S32750 and S32760 • Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking • High mechanical strength and fatigue resistance • Custom sizes, coatings, and pressure classes available upon request Conclusion: DIN 2633 super duplex steel flanges PN 16 from Ladhani Metal Corporation are designed to meet the most demanding operational requirements in highly corrosive and high-pressure environments. With unmatched strength and corrosion resistance, these flanges are ideal for offshore, marine, chemical, and industrial applications. For technical specifications, custom designs, or pricing information, contact Ladhani Metal Corporation today.

Send Message