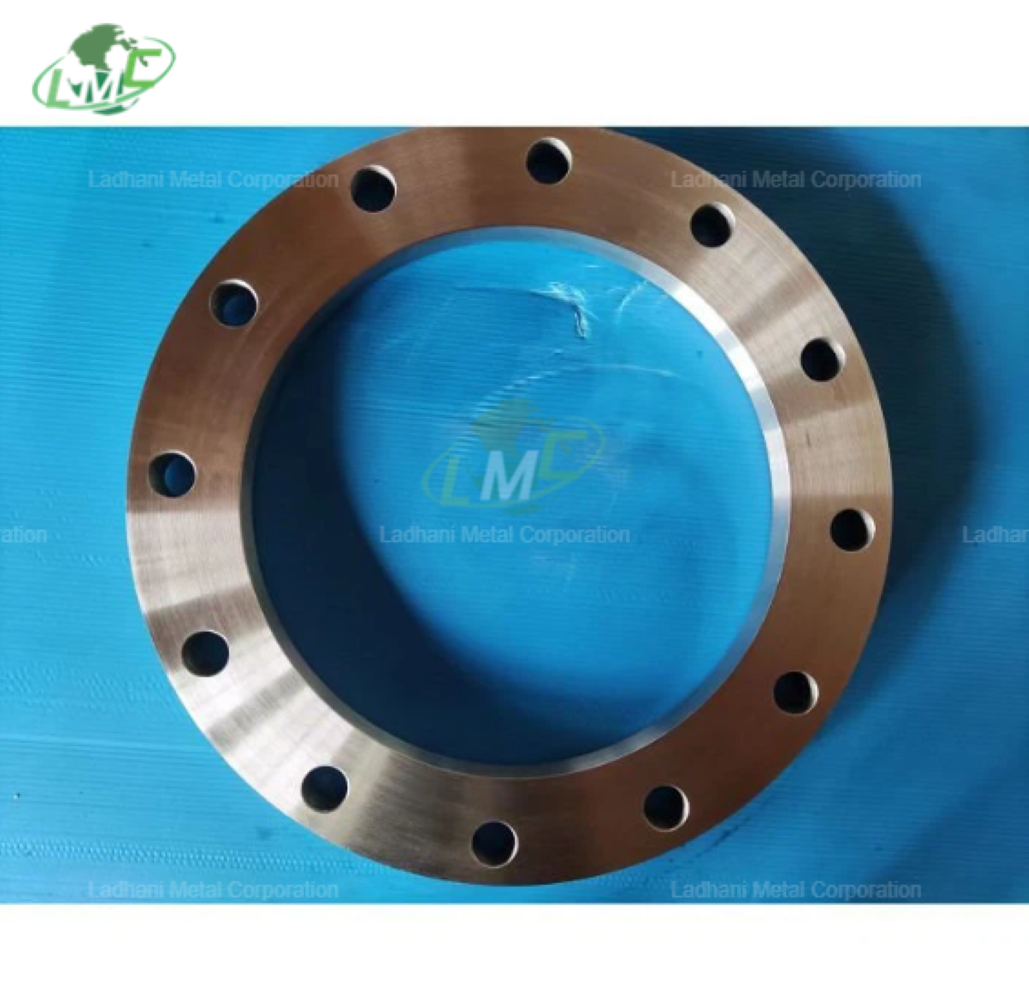

DIN 2576 Duplex Flanges PN 10 are robust, slip-on flanges engineered from duplex stainless steel, designed for piping systems operating under low to medium pressures. Manufactured according to the DIN 2576 standard, these flanges combine high mechanical strength with excellent corrosion resistance, particularly in chloride-rich and aggressive chemical environments. The slip-on configuration allows for simple positioning over the pipe and secure welding, ensuring accurate alignment and strong sealing integrity in a variety of industrial applications. Ladhani Metal Corporation is a renowned manufacturer and global exporter of duplex steel flanges, offering products that conform to international specifications in terms of dimensions, metallurgy, and performance. DIN 2576 duplex flanges are especially valued in industries requiring resistance to pitting, crevice corrosion, and stress corrosion cracking, including offshore, chemical, and wastewater systems. Pressure Rating: • PN 10 (10 bar / 145 psi): Suitable for moderate-pressure systems requiring long-term performance in harsh environments. Flange Types: • Slip-On Flanges Designed to slide over the pipe and be welded on both sides, these flanges offer easy installation and secure mechanical integrity. • Flat Face (FF) Flanges Used in conjunction with flat gaskets and flat mating surfaces, ideal for connections involving non-metallic or cast components. Duplex Stainless Steel Grades and Composition: Duplex 2205 (UNS S32205 / S31803) Composition: • Chromium (Cr): 21.0 – 23.0% • Nickel (Ni): 4.5 – 6.5% • Molybdenum (Mo): 2.5 – 3.5% • Nitrogen (N): 0.14 – 0.20% • Iron (Fe): Balance Applications: Duplex 2205 offers twice the yield strength of conventional stainless steels with superior resistance to chloride-induced corrosion. Common applications include chemical processing, desalination, marine systems, and structural components in offshore platforms. Applications of DIN 2576 Duplex Flanges: • Offshore and Marine Engineering Ideal for seawater cooling systems, risers, and structural supports exposed to harsh marine environments. • Chemical and Petrochemical Industries Used in systems handling aggressive acids, chlorides, and solvents where standard stainless steels are insufficient. • Water Treatment and Desalination Applied in brine systems, high-salinity piping, and reverse osmosis plants for their resistance to pitting and scaling. • Pulp and Paper Industry Resists corrosion from bleaching chemicals and process fluids under high pressure. • Oil and Gas Suitable for pressure control systems, separators, and sour service applications. • Structural and Pressure Vessel Fabrication Used in tanks, pressure vessels, and piping subjected to mechanical and corrosive stress. Key Features: • Compliant with DIN 2576 standards • PN 10 pressure rating for moderate-pressure use • Excellent resistance to chloride stress corrosion, pitting, and crevice corrosion • High strength-to-weight ratio, reducing component size and cost • Available in Duplex 2205, Super Duplex 2507, and other custom grades • Slip-on design ensures quick and accurate pipe connections • Flat face options compatible with a variety of gaskets and materials • Ideal for chemical, marine, oil and gas, and water treatment sectors • Custom dimensions, face types, and surface finishes available Conclusion: DIN 2576 Duplex Flanges PN 10 from Ladhani Metal Corporation provide outstanding durability and corrosion resistance for challenging industrial environments. With availability in Duplex 2205 and Super Duplex 2507, these flanges are a reliable solution for systems exposed to high chlorides, pressure, and temperature. For technical specifications, grade selection, or project-specific orders, contact Ladhani Metal Corporation today.

Send Message