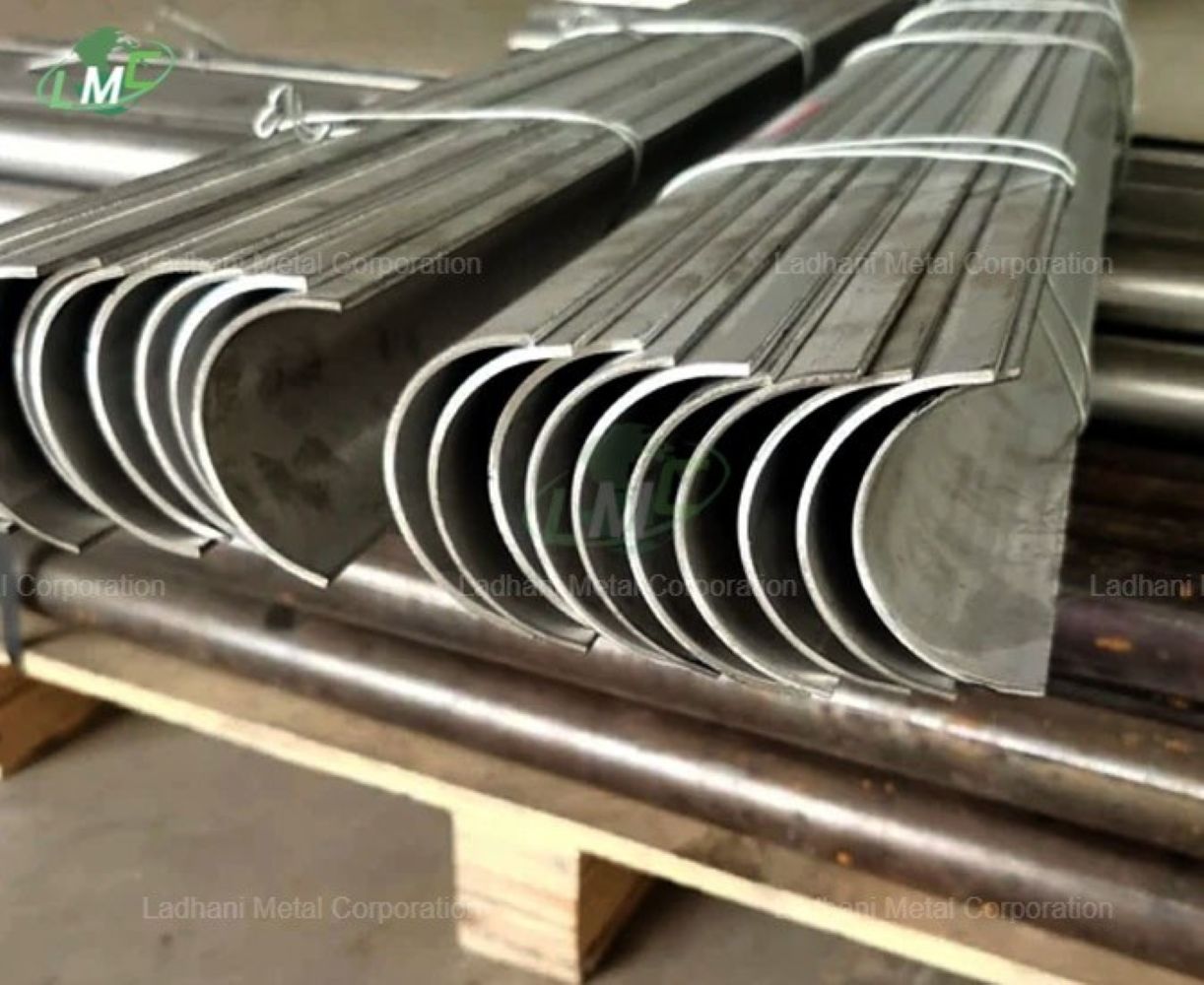

Ladhani Metal Corporation offers 1Cr20Ni14Si2 Outer Half Round 90 Degree Bend Tube Shields designed to protect the outer curvature of U-bends and 90-degree tube turns in high-temperature and moderately corrosive service environments. The half-round shields are precision-formed to fit the external radius of return bends, offering direct protection against erosion, scaling, and impact from soot blowing and ash-laden gas flow. 1Cr20Ni14Si2 shields are suitable for use in thermal power stations, waste heat recovery boilers, incinerators, and petrochemical plants operating at elevated temperatures. Ladhani Metal Corporation is a leading manufacturer, supplier, and exporter of 1Cr20Ni14Si2 Outer Half Round 90 Degree Bend Tube Shields, offering customizable sizes and configurations to meet the demands of varied industrial applications. 1Cr20Ni14Si2 Grade Chemical Composition – Austenitic Heat-Resistant Steel • Carbon (C): ≤ 0.15% • Manganese (Mn): ≤ 1.50% • Phosphorus (P): ≤ 0.035% • Sulfur (S): ≤ 0.030% • Silicon (Si): 1.50 – 2.50% • Chromium (Cr): 19.0 – 21.0% • Nickel (Ni): 13.0 – 15.0% • Iron (Fe): Balance Uses • Protects 90-degree bends in superheater and reheater tubes in power generation systems • Used in WHRBs and HRSGs exposed to oxidizing and dry gas flow • Shields heat exchanger and furnace tubing from scale formation and high-velocity gas erosion • Suitable for return bends in chemical and thermal processing units requiring heat durability Features • High oxidation resistance – Enhanced by silicon for long-term performance at elevated temperatures • Excellent heat stability – Resists deformation, fatigue, and creep during prolonged thermal cycling • Mechanical durability – Maintains structural integrity in harsh operating conditions • Precision-formed fit – Matches tube curvature for optimal surface coverage and protection • Adaptable installation – Can be welded, banded, or clamped to suit on-site assembly methods • Broad availability – Offered in a range of diameters, wall thicknesses, and arc lengths Applications • Thermal power plants – Shields superheater and reheater bends from erosion and surface scaling • Petrochemical and chemical processing – Protects tubing in high-temperature reaction and heating zones • Waste incineration and heat recovery – Guards bends in units subjected to corrosive and abrasive gas streams • Cement and metallurgy industries – Applied in tube shields for high-heat rotary kilns and preheater units Conclusion The 1Cr20Ni14Si2 Outer Half Round 90 Degree Bend Tube Shield by Ladhani Metal Corporation offers dependable protection for tube bends in high-temperature and oxidizing environments. With enhanced thermal and oxidation resistance, these shields extend the life of heat-exposed tubing while maintaining mechanical reliability. For product customization, material selection, or technical specifications, contact Ladhani Metal Corporation. #Mumbai #Pune #Ahmedabad #Vadodara #Surat #Rajkot #Jamnagar #Bharuch #Ankleshwar #Vapi #Delhi #Faridabad #Ghaziabad #Noida #Gurugram #Chennai #Coimbatore #Tiruchirappalli #Hyderabad #Visakhapatnam #Vijayawada #Bangalore #Mangalore #Mysore #Kolkata #Durgapur #Asansol #Bhubaneswar #Rourkela #Raipur #Bhilai #Bilaspur #Nagpur #Nashik #Aurangabad #Indore #Bhopal #Jabalpur #Kanpur #Lucknow #Varanasi #Jaipur #Kota #Udaipur #Jodhpur #Chandigarh #Ludhiana #Jalandhar #Haridwar #Dehradun #Agra #Meerut #Aligarh #Moradabad #Bareilly #Mathura #Gwalior #Rewa #Satna #Sagar #Ujjain #Ratlam #Solapur #Kolhapur #Amravati #Akola #Jalgaon #Latur #Sangli #Nanded #Gandhinagar #Bhavnagar #Mehsana #Surendranagar #Junagadh #Nadiad #Nizamabad #Karimnagar #Warangal #Kurnool #Nellore #Tirupati #Salem #Erode #Madurai #Tirunelveli #Thoothukudi #Belgaum #Hubli #Tumkur #Hassan #Cuttack #Sambalpur #Jamshedpur #Ranchi #Dhanbad #Patna #Gaya #Muzaffarpur #TubeShield #HalfTubeShield #SSHalfRoundShield #BoilerTubeShield #BoilerShield #TubeProtection #Tubeshieldmanufacturer #BoilerTubeProtection #SSTubeShield #MetalIndustry #SteelFabrication #IndustrialShielding #SS304Shield #SS316Shield #StainlessSteelShield #WeldOnShield #WeldedTubeShield #TubeCladding #BoilerTubeSleeve #TubeSleeve #MetalFabrication #PowerPlantSupplies #RefineryEquipment #ProcessIndustry #MetalComponent #TubeShieldForBoilers #BoilerParts #SteelSolutions #TubeShieldManufacturer #TubeShieldSupplier #SSShielding #IndustrialTubeShield #BoilerTubeGuard #CustomMetalParts #SteelIndustryIndia #MetalEngineering #HeavyIndustrySupply #StainlessSteelIndia #SteelExporters #MetalComponentExport #FabricatedProducts #SteelDealer #IndustrialSupplyIndia #BoilerTubeFittings #TubeShieldingSolutions #HalfTubeCover #HeatExchangerShield #halftubeshield #utypehalftubeshield #tubeshieldexporter

Send Message