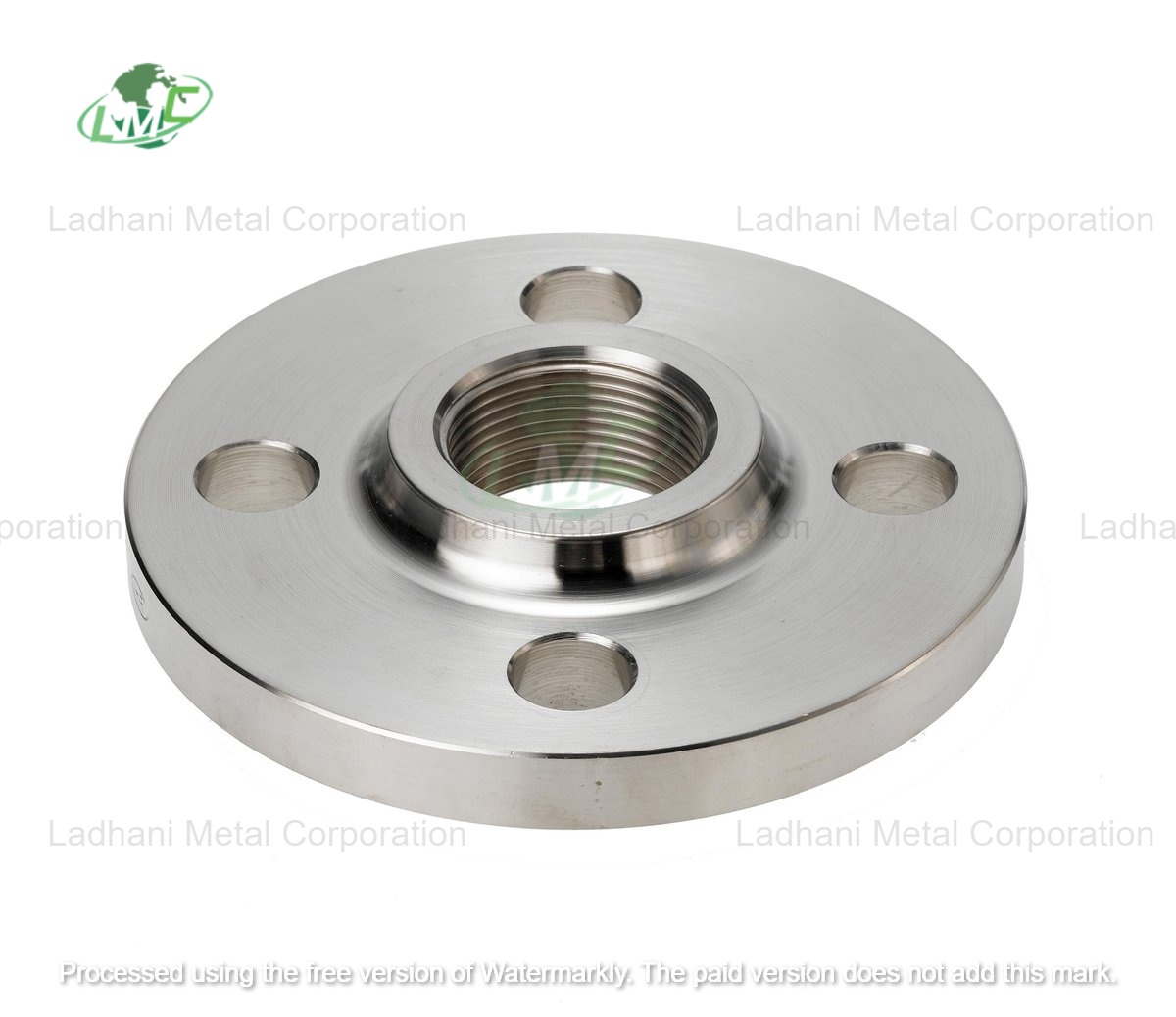

DIN 2566 Inconel flanges PN 16 are engineered for high-performance, medium-pressure piping systems exposed to extreme temperatures, corrosive chemicals, and high mechanical stress. Manufactured in compliance with DIN 2566 standards, these threaded flanges provide a secure, weld-free connection ideal for critical applications in challenging industrial environments. Ladhani Metal Corporation is a leading manufacturer and global exporter of Inconel flanges, offering precision-crafted products with superior resistance to heat, oxidation, and corrosive media. DIN 2566 Inconel flanges are trusted across industries such as aerospace, chemical processing, marine, thermal power, and nuclear energy. Flange Types: • Threaded (Screwed) Flanges: Allow for fast assembly and disassembly without welding, ideal for systems requiring frequent maintenance. • Raised Face (RF) Flanges: Enhances sealing performance by concentrating gasket pressure at the sealing surface. • Flat Face (FF) Flanges: Typically used with flat-faced equipment and non-metallic piping systems under moderate pressure. • Forged Threaded Flanges: Forged for improved mechanical properties, dimensional accuracy, and long-term reliability. • Custom-Machined Flanges: Available on request in custom dimensions, pressure classes, and material combinations. Available Inconel Grades and Composition: 1. Inconel 600 (UNS N06600) • Nickel (Ni): ≥ 72% • Chromium (Cr): 14.0 – 17.0% • Iron (Fe): 6.0 – 10.0% • Excellent resistance to oxidation, corrosion, and high temperatures. Applications: Furnace components, heat exchangers, food processing, and chemical vessels. 2. Inconel 625 (UNS N06625) • Nickel (Ni): ≥ 58% • Chromium (Cr): 20.0 – 23.0% • Molybdenum (Mo): 8.0 – 10.0% • Niobium + Tantalum (Nb + Ta): 3.15 – 4.15% • Superior resistance to seawater, acidic environments, and high mechanical stress. Applications: Marine systems, offshore platforms, exhaust systems, and chemical plant components. 3. Inconel 718 (UNS N07718) • Nickel (Ni): 50.0 – 55.0% • Chromium (Cr): 17.0 – 21.0% • Iron (Fe): Balance • Niobium + Tantalum (Nb + Ta): 4.75 – 5.5% • Molybdenum (Mo): 2.8 – 3.3% • Excellent high-temperature strength, creep resistance, and fatigue resistance. Applications: Aerospace turbines, nuclear reactors, high-speed rotating components, and pressure vessels. Applications of DIN 2566 Inconel Flanges: • Aerospace and Jet Engines: High-temperature, high-stress components • Petrochemical and Chemical Processing: Resistant to aggressive acids and solvents • Marine and Subsea Engineering: Excellent in chloride-rich and saltwater environments • Power Generation: Used in nuclear, geothermal, and thermal power systems • High-Performance Exhaust and Heat Systems: Reliable under thermal cycling and oxidation Key Features: • Manufactured to DIN 2566 standard with PN 16 pressure rating • Exceptional resistance to oxidation, pitting, and chemical corrosion • Outstanding performance under thermal stress and cyclic loading • Threaded design allows for easy, weld-free installation • High tensile and creep strength, especially at elevated temperatures • Supplied with complete MTCs, inspection reports, and full traceability Conclusion: DIN 2566 Inconel flanges PN 16 from Ladhani Metal Corporation are built to handle the most demanding operating conditions in high-temperature and corrosive environments. With premium-grade materials like Inconel 600, 625, and 718, these flanges offer unmatched durability, thermal stability, and corrosion resistance. For technical support, custom orders, or large-scale procurement, contact Ladhani Metal Corporation today.

Send Message