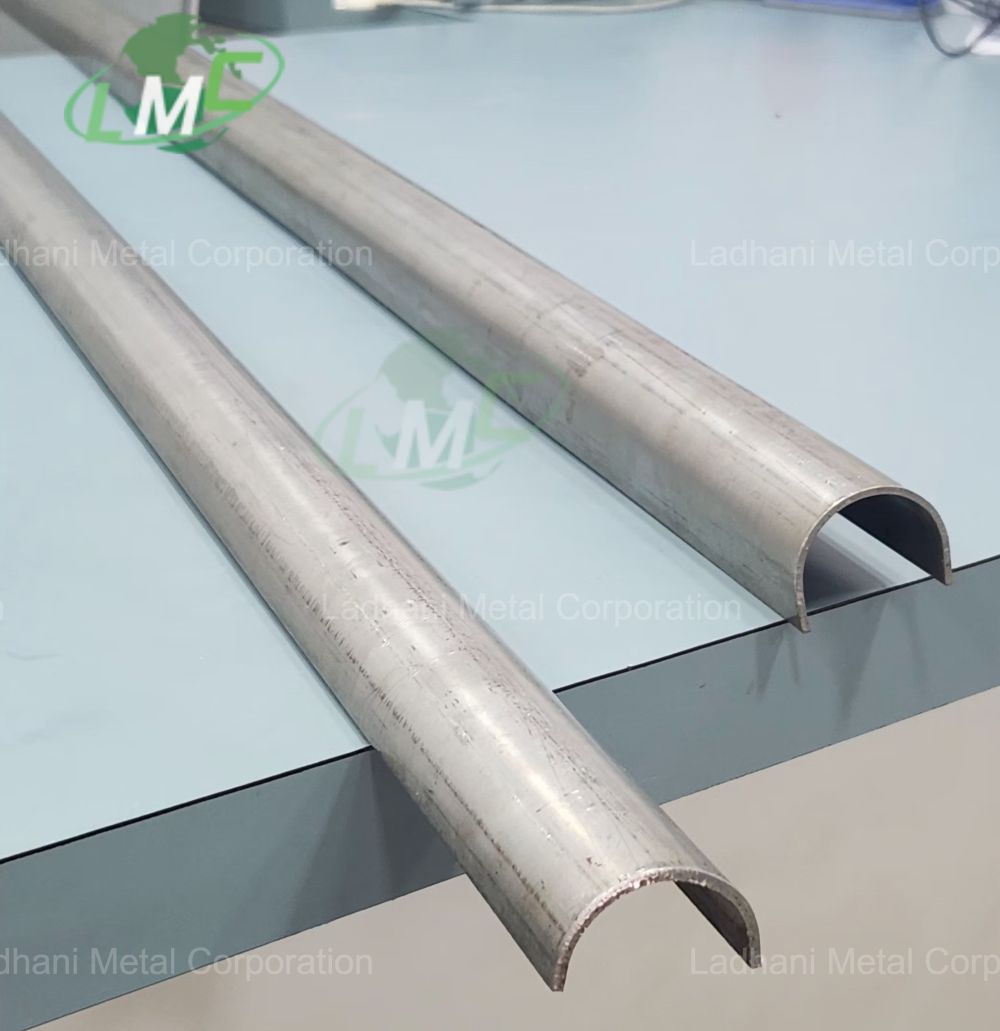

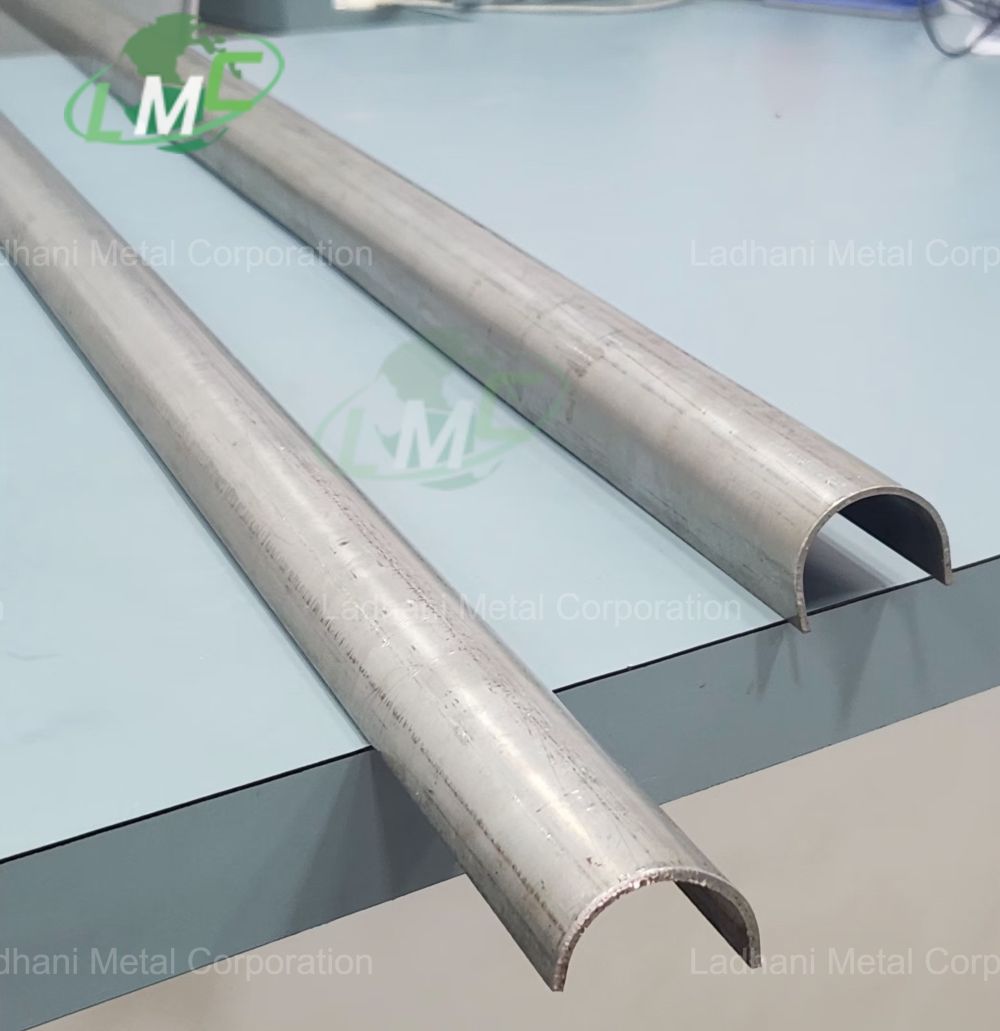

Half Round Tube Shield Half Round Tube Shields by Ladhani Metal Corporation are engineered protective components designed to safeguard heat exchanger, boiler, and superheater tubes from erosion, scaling, thermal stress, and corrosion. These shields are commonly applied in power generation, petrochemical, and high-temperature industrial systems where tube surfaces are subjected to flue gas turbulence, slag buildup, and elevated temperatures. Their half-round configuration ensures secure installation and reliable performance over curved or straight tube sections, extending equipment life and reducing maintenance costs. SS 304L U Type Inner Half Round Tube Shield The SS 304L U Type Inner Half Round Tube Shield is manufactured from stainless steel grade 304L, a low-carbon version of SS 304. It offers improved weldability and resistance to intergranular corrosion without sacrificing strength or oxidation resistance. The inner U-type design is specifically tailored to protect the inner arc of U-bend tubes, an area frequently exposed to turbulent flow, localized scaling, and corrosive gases that accelerate material degradation. • Inner U Type Half Round Tube Shield – Covers the inner curvature of U-bend tubes, shielding against erosion, scaling, and corrosion caused by turbulent gas flow and heat concentration. Ladhani Metal Corporation is a well-known manufacturer, supplier, and exporter of SS 304L U Type Inner Half Round Tube Shields, offering high-quality and custom-built protection for thermal and chemical process applications. Chemical Composition of SS 304L – Low Carbon Austenitic Stainless Steel • Carbon (C): ≤ 0.035% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.00% • Chromium (Cr): 18.0 – 20.0% • Nickel (Ni): 8.0 – 13.0% • Iron (Fe): Balance Applications: Best suited for environments requiring corrosion resistance and thermal stability, especially where welding is involved or where intergranular corrosion must be minimized. Uses • Inner bend protection in superheaters, reheaters, and economizer tubes exposed to flue gas turbulence • Installed in the return bends of waste heat recovery boilers (WHRBs) and HRSGs • Applied in curved tube sections of steam reformers and heat exchangers handling moderately corrosive gases • Used in condensers and evaporators in power and process plants • Ideal for environments where welded tube components are at risk of intergranular corrosion Features • Superior corrosion resistance – Excellent protection against oxidation and scaling in high-temperature service • Low carbon content – Reduces carbide precipitation during welding, minimizing risk of corrosion at weld zones • Inner arc shielding – Specifically designed to protect the internal arc of U-bends from erosion and thermal fatigue • Precision fabrication – Manufactured to fit the exact radius and diameter of the tube bend • Quick and easy installation – Mountable using clamps, stainless steel bands, or tack welding • Enhanced durability – Extends the life of tubes in cyclic and corrosive operating environments Applications • power plants – Protects inner U-bend surfaces in superheaters and heat recovery sections from slag and heat exposure • petrochemical industries – Shields internal arcs in process heaters and reactors operating with acidic gases • waste heat recovery – Prevents inner arc degradation in WHRBs and HRSGs under variable temperature loads • chemical plants – Installed in corrosive media systems where steam and acidic vapors cause wear • industrial heaters – Used in return bends subjected to thermal cycling and corrosive combustion products Conclusion The SS 304L U Type Inner Half Round Tube Shield by Ladhani Metal Corporation – manufacturer, supplier, and exporter – is a reliable and corrosion-resistant solution for protecting the inner curvature of U-bend tubes in moderate to high-temperature environments. With its low-carbon composition and excellent thermal performance, it is ideal for systems requiring welded components and long-term durability in corrosive service conditions. For technical consultation, custom sizes, or quotations, please contact Ladhani Metal Corporation.

Send Message