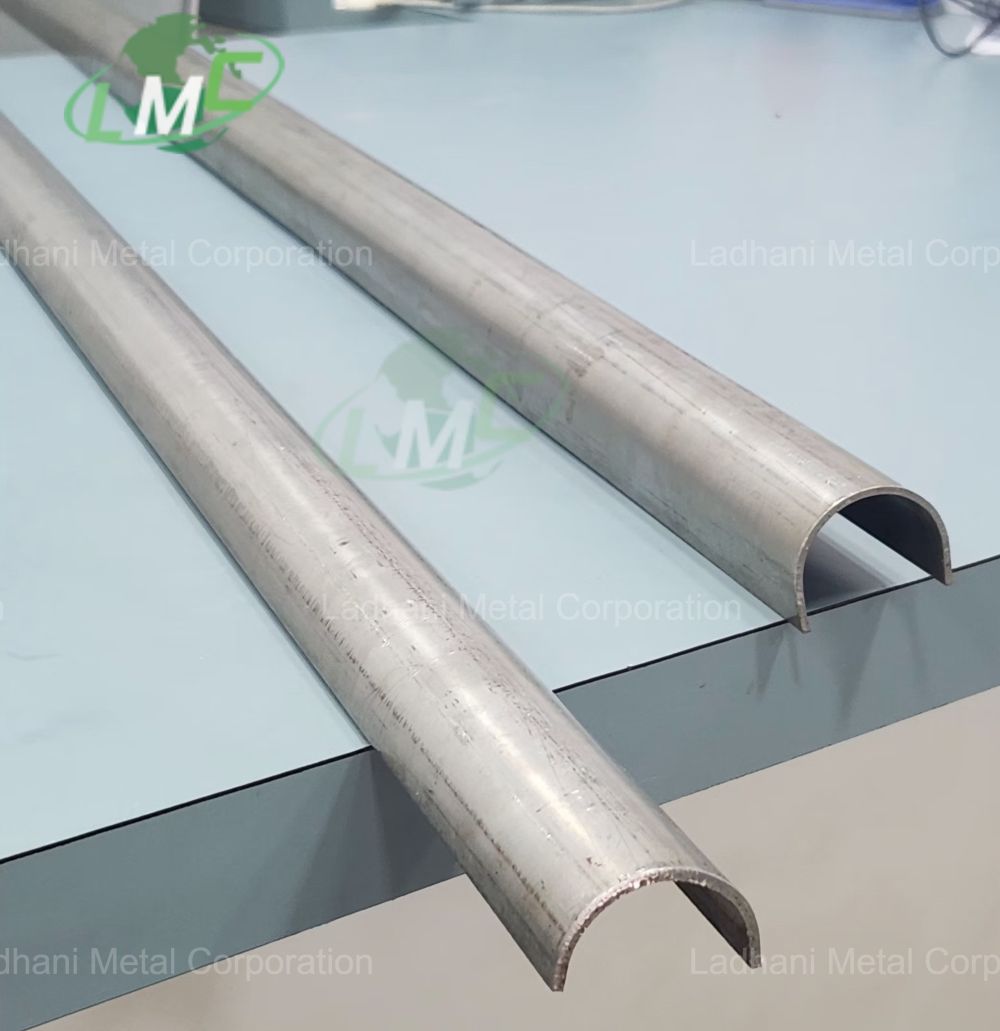

Product name: ASTM B338 titanium Seamless Tubes for Condensers Standard:ASTM B338 ASTM B861 ASTM B862 Material:Titanium Gr7 Diameter:5-914mm Wall thickness:0.5-50mm Length:Max 16000mm Surface:Pickling surface/Polished Type:Seamless, welded Application:Heat Exchanger, chemical industry etc. Technique:Rolled ASTM B338 titanium Seamless Tubes for Condensers ASTM B338 Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers ASTM B338 covers 28 grades of seamless and welded titanium alloy tubes for surface condensers, evaporators, and heat exchangers. Standard ASTM B338, ASME SB338 Regular Grade Grade 1 Grade 2 Outer Diameter 12.7mm 15mm 17mm 19mm 25.4mm 31mm etc. Wall thickness 0.9mm/1.0mm/1.2mm/1.5mm Length 3000 - 6000mm or other economical lengths Finish Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF Form Straight titanium Pipe, Coiled titanium tube Type Seamless, ERW, EFW, Welded, Fabricated End Plain End, Beveled End, Treaded Marking Standard, Grade, OD, Thickness, Length, Heat No. (Or as per customer's request.) Application Oil Tube, Gas Tube, Fluid Tube, Boiler and Heat exchanger Value Added Service Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. Test Certificate Mill Test Certificate EN 10204/3.1,TPI Report, EN10204/3.2 Precautions for titanium pipe processing: During the deformation process, titanium pipe will gradually reduce wall and diameter with the rotation and feeding of the rolling mill. The pipe size required by the process can be obtained only after 5 ~ 10 rolling and finishing in one rolling pass. The cold rolling pipe mill can carry out large diameter reduction and wall reduction, but the dimensional accuracy is low after rolling, and the pipe end is prone to cracking, uneven concave convex and other phenomena. The cracking phenomenon can be solved mainly by grinding and leveling before pipe blank processing; For the uneven pipe end, similar to the "fish mouth" phenomenon, flat head treatment is required in the subsequent processing process, otherwise it will cause the plug stuffy accident. Therefore, this paper analyzes from the aspects of process, tooling and equipment, in order to find out the causes of uneven concave convex of pipe end and take effective measures to solve it. Chemical composition (Wt%) ASTM No. Fe max O max N max C max H max Pd Al Bal Grade 1 0.2 0.18 0.03 0.1 0.015 - - Ti Grade 2 0.3 0.25 0.03 0.1 0.015 - - Ti Physical Properties (Min) ASTM Grade Alloy Composition Tensile Strength Yield Strength Elongation min % ksi Mpa ksi Mpa Grade 1 Unalloyed Ti ("Pure") 35A -CP1 35 240 25 170 30 Grade 2 Unalloyed Ti ("Pure") 50A -CP2 58 400 40 275 25

Send Message