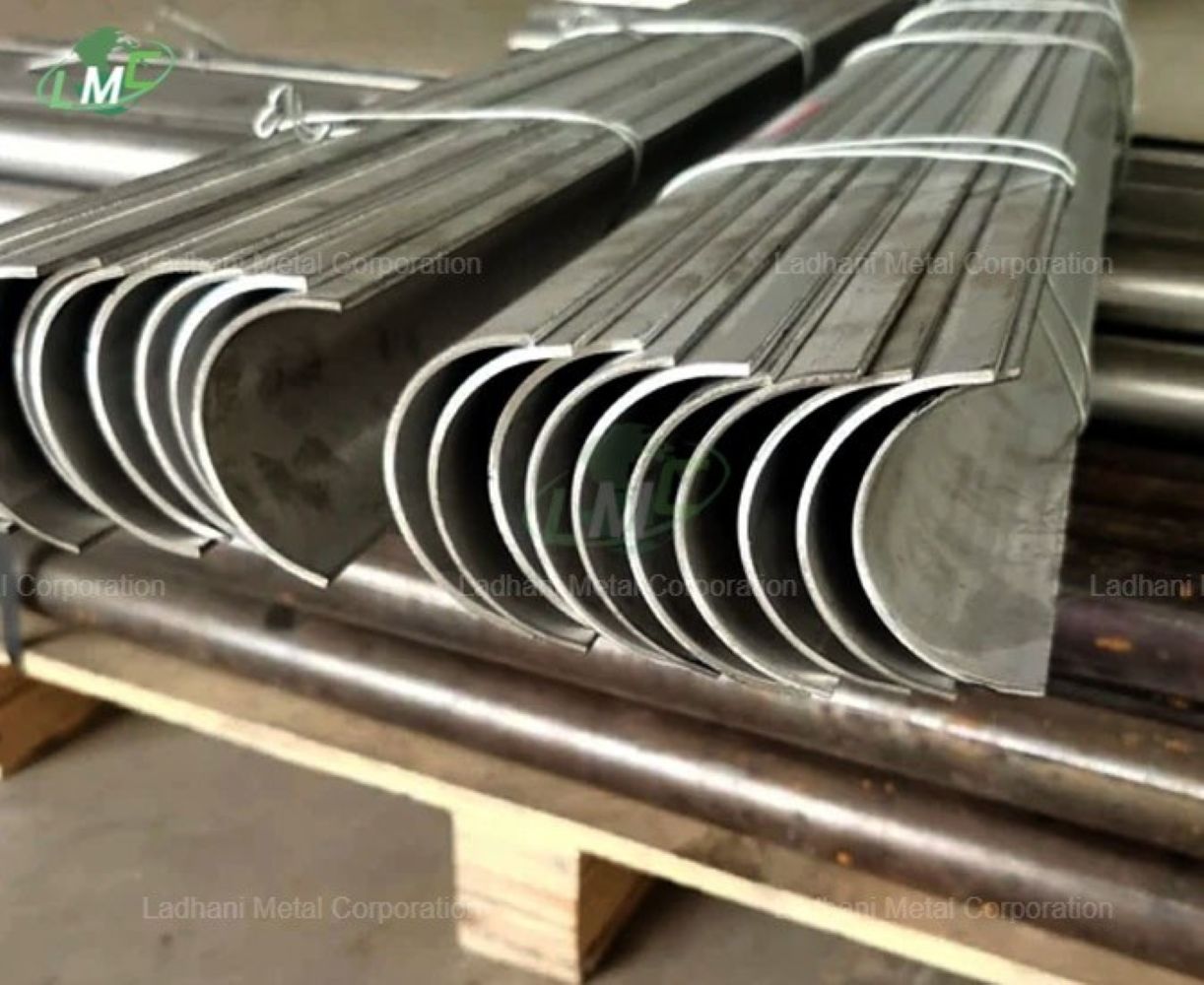

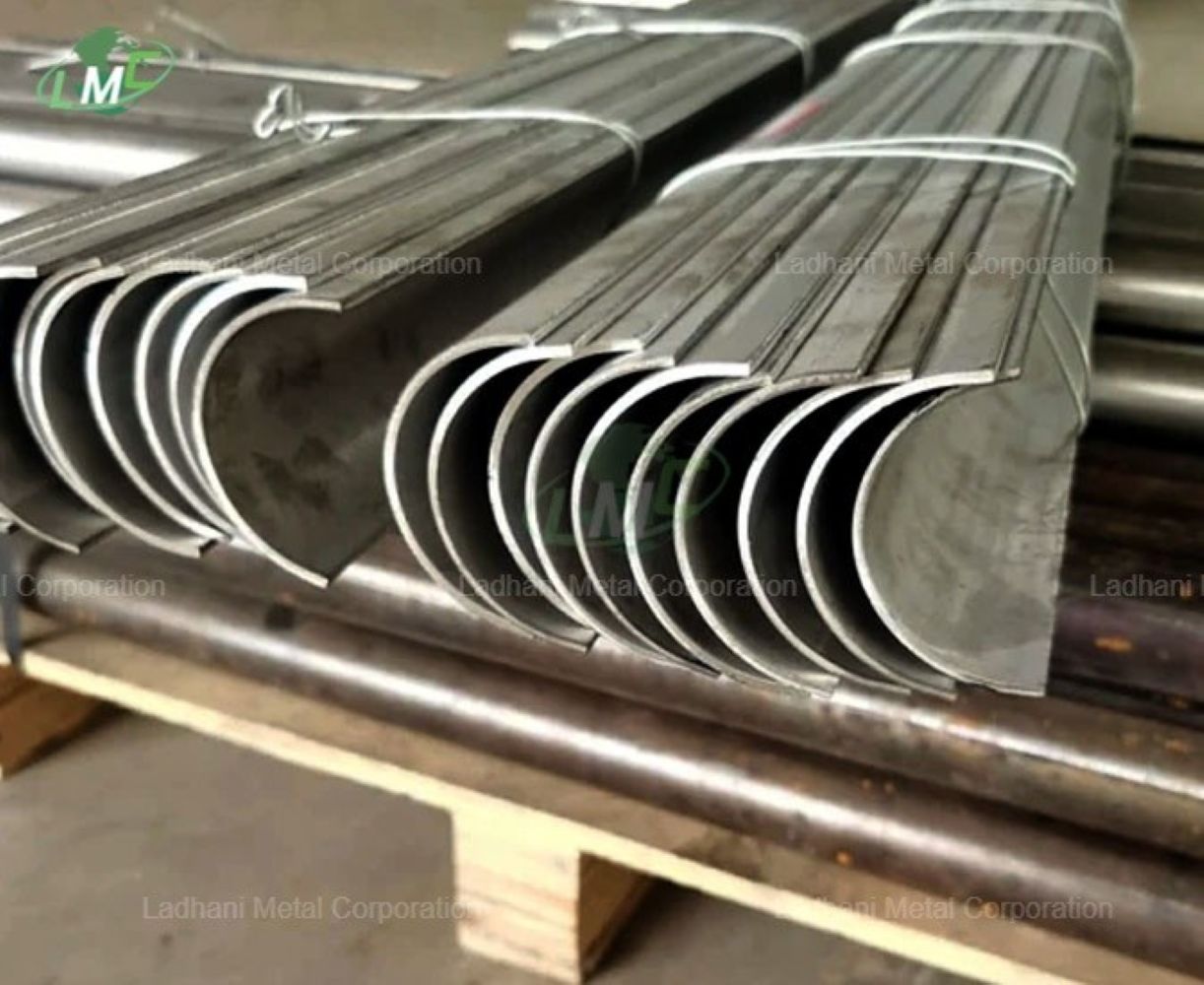

SS 310S Half Round Straight Tube Shield Half Round Tube Shield Ladhani Metal Corporation manufactures SS 310S Half Round Straight Tube Shields designed to protect straight boiler and heat exchanger tubes from high-temperature oxidation, corrosion, and mechanical erosion. SS 310S is a low-carbon version of SS 310, offering enhanced weldability and resistance to sensitization during thermal exposure. These shields are especially suited for harsh environments involving continuous or cyclic high heat, making them ideal for industrial boilers, fired heaters, and heat recovery systems. SS 310S Half Round Straight Tube Shield The SS 310S Half Round Straight Tube Shield is fabricated to tightly fit over straight tube surfaces, offering durable protection in thermal processing units. Its resistance to scaling at temperatures up to 1100°C and excellent mechanical strength under elevated temperatures makes it reliable for shielding heat-affected tubes. With easy installation methods such as tack welding, clamping, or banding, these shields minimize downtime and maintenance in critical operations. Ladhani Metal Corporation is a leading manufacturer, supplier, and exporter of SS 310S Half Round Straight Tube Shields, offering custom solutions to meet the demanding conditions of thermal power plants, petrochemical facilities, and steam reformers. Material Grade SS 310S – Austenitic stainless steel with low carbon content and superior heat and oxidation resistance. Chemical Composition of SS 310S • Carbon (C): ≤ 0.08% • Manganese (Mn): ≤ 2.00% • Phosphorus (P): ≤ 0.045% • Sulfur (S): ≤ 0.030% • Silicon (Si): ≤ 1.50% • Chromium (Cr): 24.0 – 26.0% • Nickel (Ni): 19.0 – 22.0% • Iron (Fe): Balance Applications: Recommended for continuous high-temperature service in aggressive gas environments, especially where welding and corrosion resistance are key. Uses • Shielding straight tubes in superheaters, reheaters, and steam coil systems • Protection against flue gas erosion in waste heat boilers • Heat shielding in fired process heaters and refinery furnaces • Lining straight tube segments in chemical and fertilizer heat exchangers • Defending against scaling and surface degradation in steam reformers Features • Low carbon for better weldability – Prevents sensitization and intergranular corrosion • High resistance to scaling – Maintains integrity under continuous exposure to extreme heat • Durable and long-lasting – Withstands mechanical and thermal fatigue • Available in custom sizes – Fabricated to match exact tube diameters and operating conditions • Quick installation – Compatible with standard weld-on, clamp-on, or banded attachment methods • High service life – Reduces tube wear and lowers maintenance frequency Applications • power generation – Installed on straight boiler tubes in areas with high thermal load and flue gas flow • refineries – Protects tubes in process heaters from oxidation and heat-related damage • petrochemical plants – Used in straight sections of heat exchangers and reformer coils • WHRB systems – Improves durability of tubes in gas turbine exhaust recovery units • fertilizer industry – Extends lifespan of tube sections exposed to acidic and high-temperature gas streams Conclusion The SS 310S Half Round Straight Tube Shield from Ladhani Metal Corporation provides superior protection in high-temperature environments, offering excellent oxidation resistance, long-term structural performance, and easy adaptability. Its low carbon content makes it suitable for welded applications where corrosion resistance must be preserved. Engineered for precision and performance, this shield is a reliable choice for heavy-duty thermal systems. For technical assistance, custom orders, or quotes, contact Ladhani Metal Corporation.

Send Message