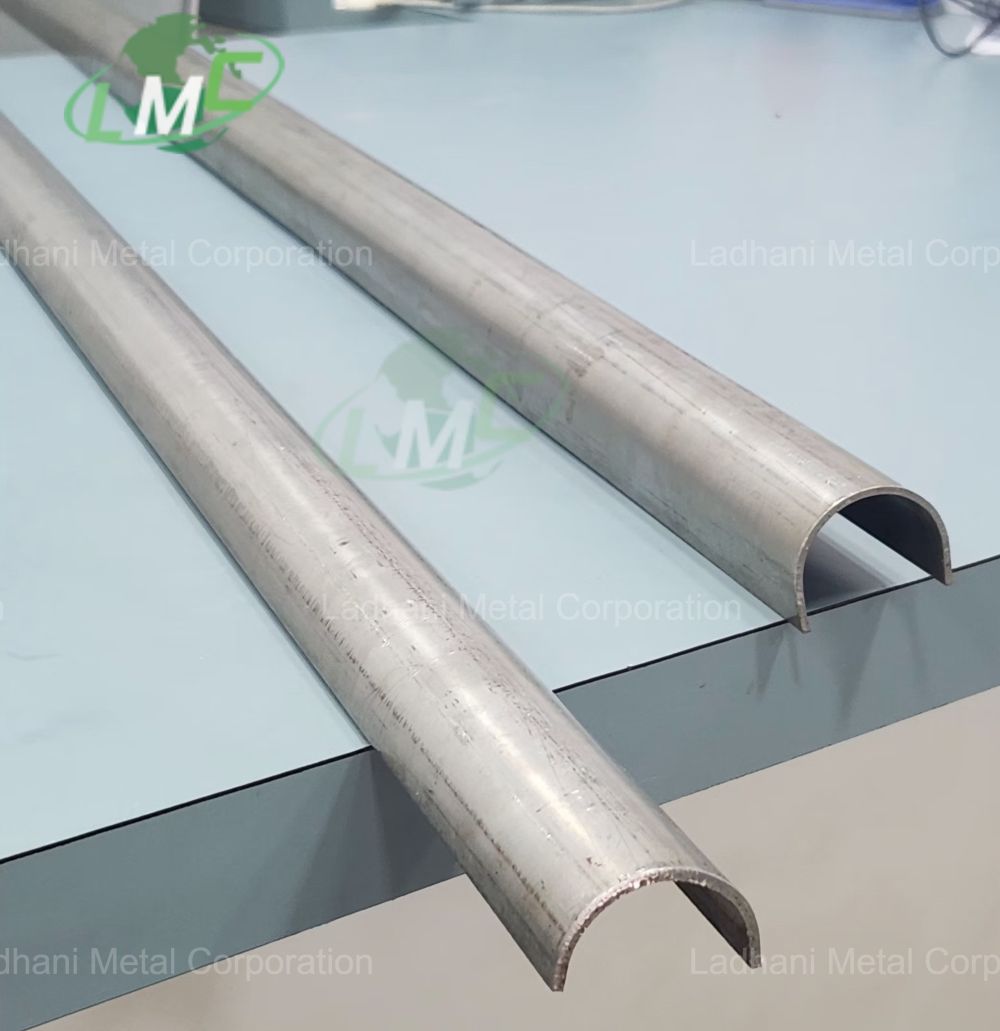

Ladhani Metal Corporation manufactures SS Arc Tube Shields engineered to provide maximum protection for boiler tubes operating under severe thermal and erosive conditions. These shields are designed with a curved or arc profile to cover specific tube sections that are most vulnerable to flue gas turbulence, abrasive ash particles, and soot blower impact. Widely used in superheaters, reheaters, economizers, and waste heat recovery boilers, SS Arc Tube Shields ensure extended service life, reduced downtime, and improved efficiency of boiler systems. Function of SS Arc Tube Shields • Protect tube surfaces from localized erosion and high-temperature oxidation • Provide angular coverage in zones most affected by flue gas and ash flow • Extend tube life and minimize costly replacements • Enhance operational reliability in high-stress boiler environments Ladhani Metal Corporation manufactures, supplies, and exports SS Arc Tube Shields in various radii, thicknesses, and custom-fit designs for use in power plants, WHRBs, HRSGs, and industrial steam boilers. Available Grades • SS 304 / SS 304L • SS 310 / SS 310S • SS 316 / SS 316L • SS 410 / SS 420 / SS 430 • 1Cr13 • 1Cr18Ni9Ti • 1Cr20Ni14Si2 • 1Cr25Ni20Si2 • Cr23Ni13 • Cr25Ni20 Applications: Suitable for thermal power plants, waste heat recovery boilers, HRSGs, petrochemical heaters, and cement industry boilers operating under erosive and high-temperature environments. Uses • Protects boiler tube bends, elbows, and high-impact areas • Shields against abrasive flue gas streams and soot blower erosion • Extends operational life of superheater, reheater, and economizer tubes • Reduces maintenance frequency and shutdown costs Features • High-temperature oxidation and erosion resistance • Strong mechanical integrity with precision-engineered fit • Manufactured in stainless steel and heat-resistant alloys • Easy to install, remove, and replace during boiler overhauls Applications • Power generation boilers – Protects high-erosion flue gas path tubes • Waste heat recovery boilers – Shields against abrasive gas flows • HRSGs – Ensures durability in cyclic temperature operations • Industrial and process heaters – Reliable in corrosive and scaling conditions Conclusion SS Arc Tube Shields by Ladhani Metal Corporation provide effective, long-lasting protection for boiler tubes exposed to harsh environments. Available in stainless steel grades (SS 304/304L, SS 310/310S, SS 316/316L, SS 410/420/430) and special alloys (1Cr13, 1Cr18Ni9Ti, 1Cr20Ni14Si2, 1Cr25Ni20Si2, Cr23Ni13, Cr25Ni20), these shields are precision-engineered to improve boiler tube performance, reduce wear, and deliver export-quality durability.

Send Message